Nextrom puts special into specialty fiber production

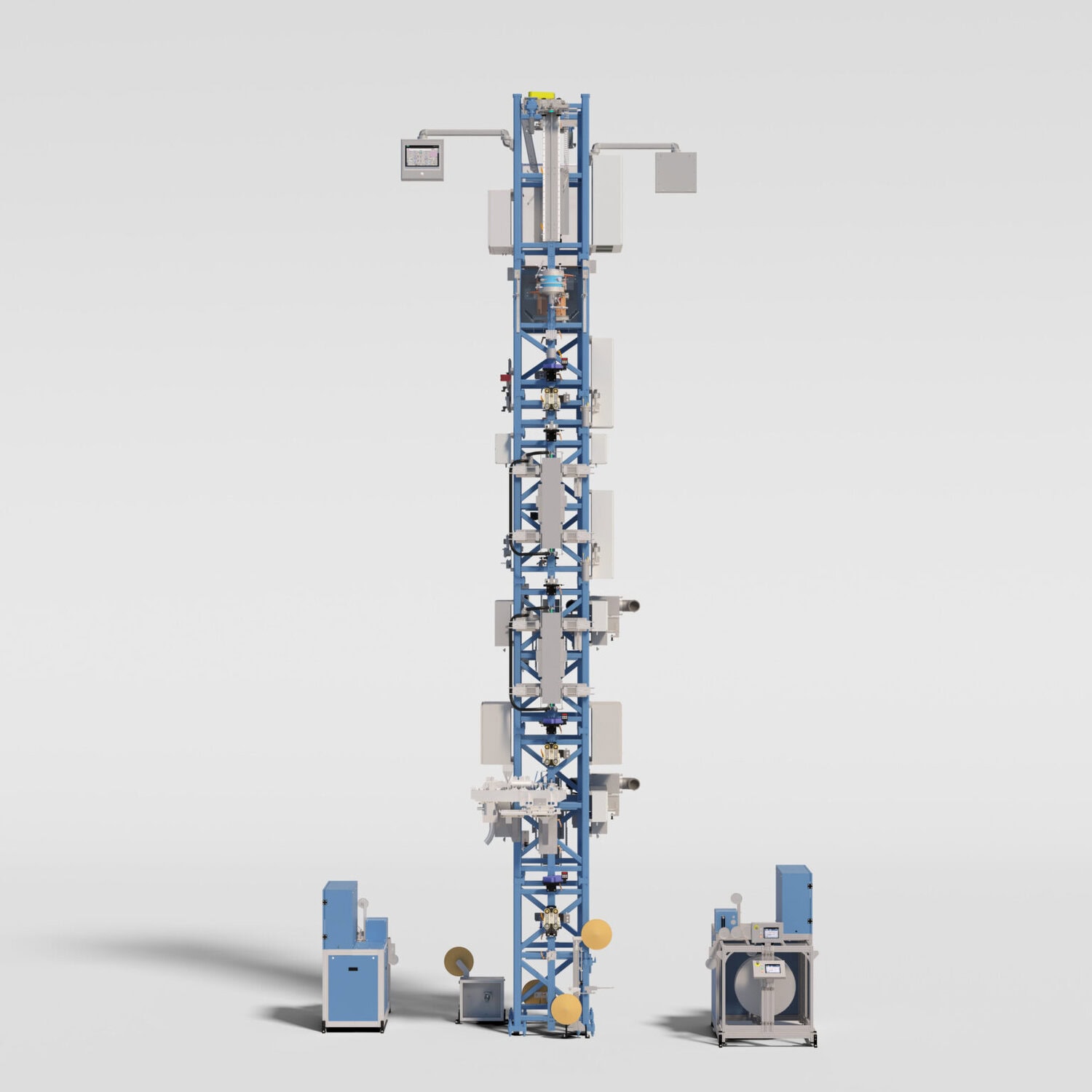

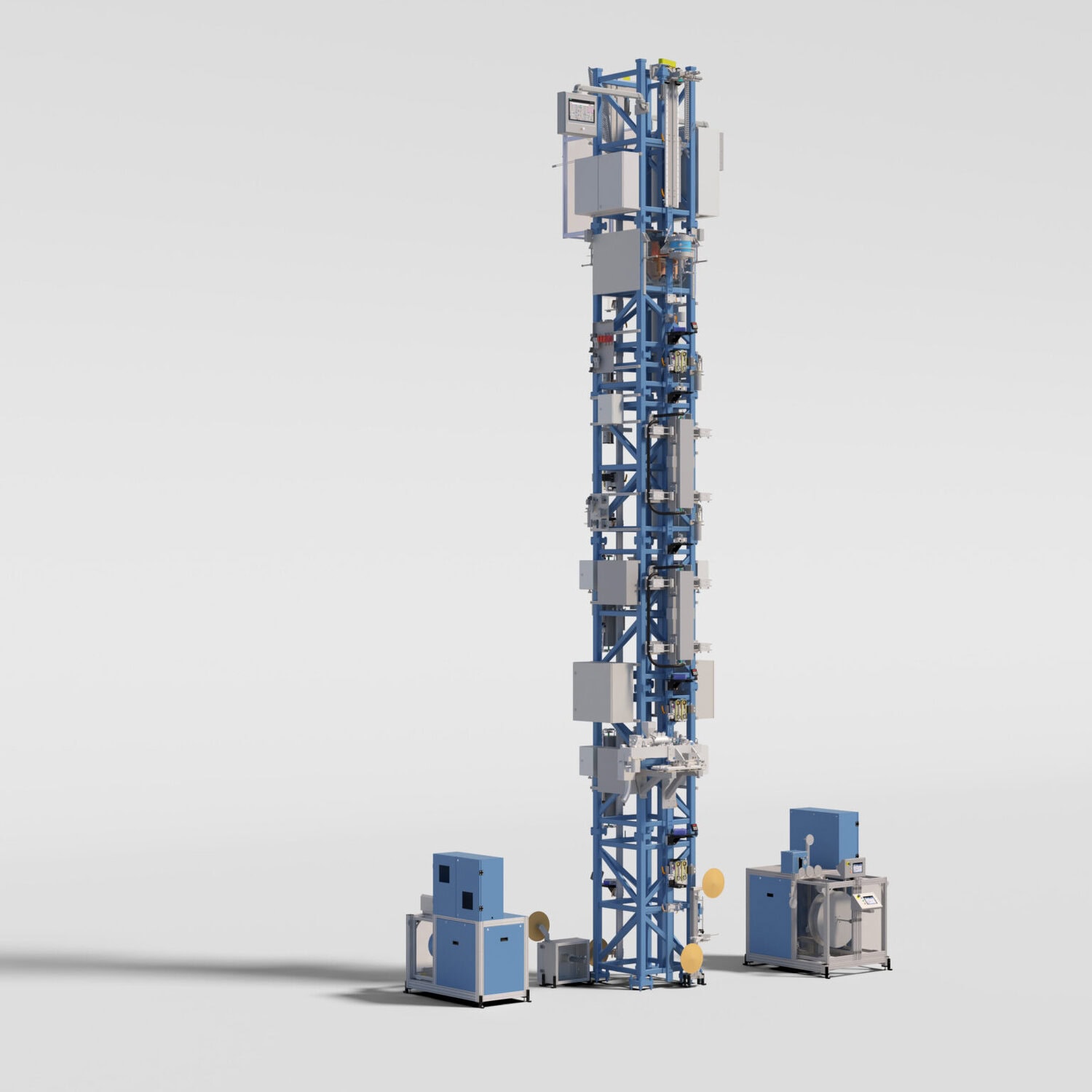

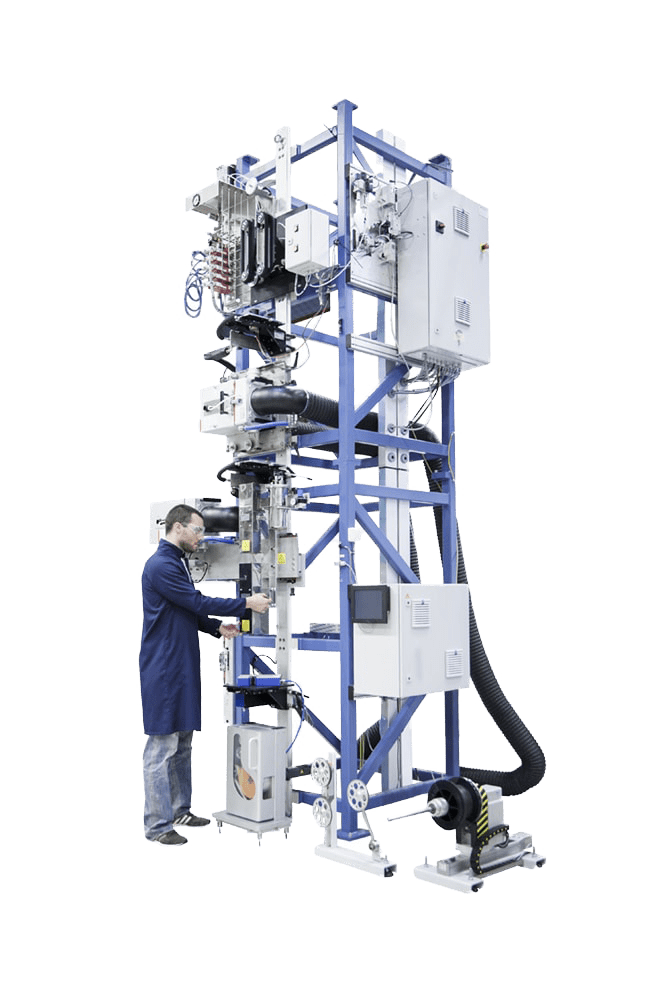

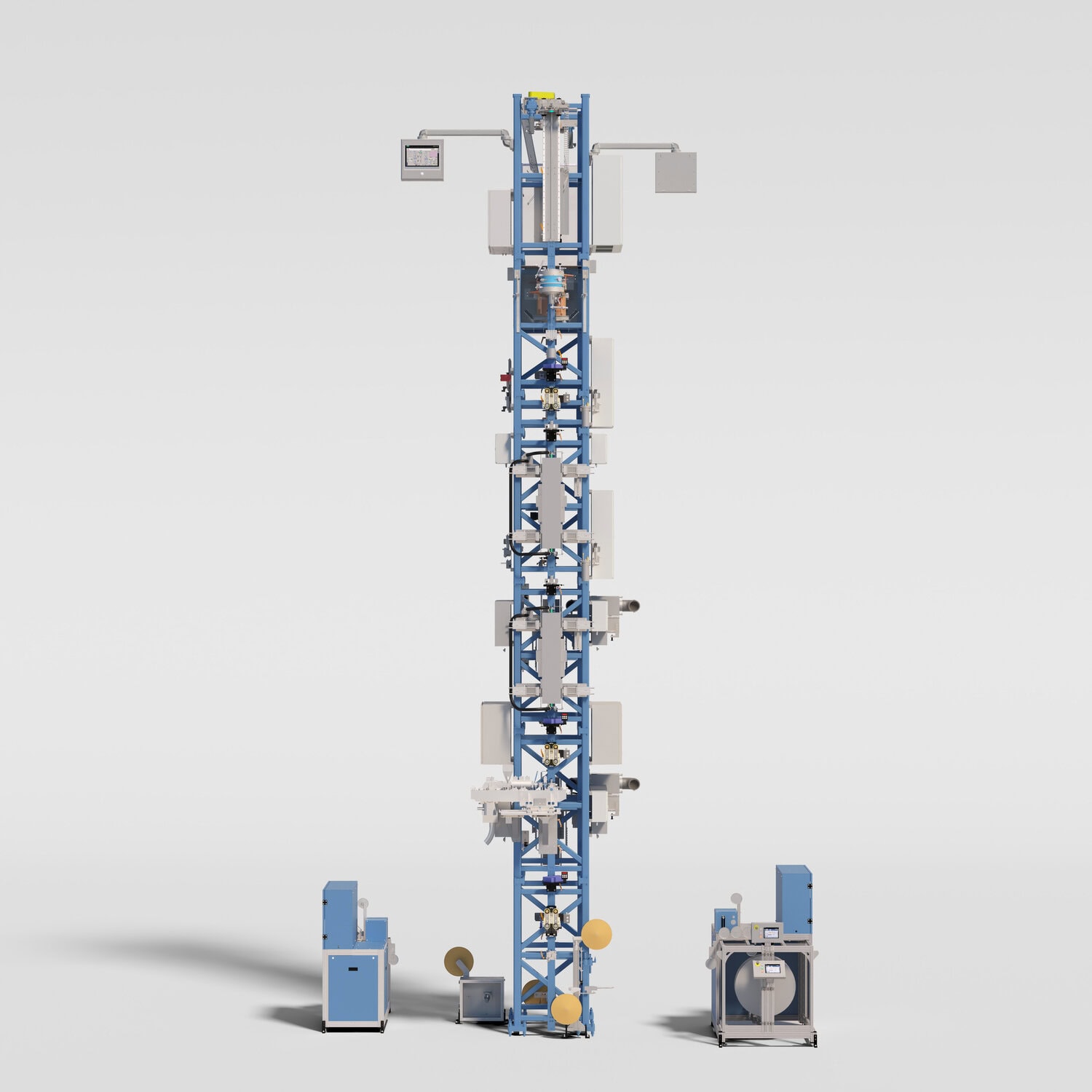

Nextrom OFC 20SF fiber draw tower for specialty fiber production

flexible specialty fiber production with Nextrom’s OFC 20 SF fiber draw tower

The OFC 20SF is a state-of-the-art specialty fiber draw tower designed to produce an extensive range of specialty fiber types—including soft glass, silica, cane and capillary tubes, and advanced designs such as microstructured (HCF), multi-mode, amplifier, laser, holey, and chalcogenide fibers and others. It´s built on a foundation of continuous innovation—ensuring it remains at the forefront of technology.

Specifications and functionalities are defined together to meet even the toughest demands. It´s perfect for industries and ideal for universities and industrial research labs looking to push the boundaries of optical fiber technology.

advantages of Nextrom specialty fiber draw tower

greater precision, higher yield, and streamlined process

process stability

Unmatched process stability and precision: With ±1°C furnace control and ±0.1 µm fiber diameter variation, the OFC 20SF delivers the most accurate bare fiber geometry on the market—proven by real-world production data.

online

measurement

Real-time control for non-circular fibers: Advanced gauge and software enable precise online measurement of hexagonal and octagonal fibers—boosting yield, cutting OPEX, and ensuring performance for high-end laser applications.

online

extrusion

Integrated polymer jacketing coating solution removes extra steps and cuts costs—leveraging Rosendahl’s pioneering extrusion expertise for proven performance in specialty fiber draw.

water-free

cooling

water-free polyimide coating system uses electrical cooling for precise, reliable temperature control—reducing costs, maintenance, and risks while ensuring high-quality specialty fiber production.

process stability

Industry-leading process stability and product quality. By maintaining furnace temperature to within ±1°C, glass viscosity is precisely controlled at the melting point, delivering bare fiber diameter variations as tight as ±0.1 µm. Backed by real-world data logs, this consistency makes it ideal for applications where dimensional accuracy is essential—the most accurate bare fiber diameter in the market.

online measurement

Measure and control non-circular fibers online. Specialized gauge and advanced software enable real-time diameter measurement for hexagonal and octagonal fibers—improving yields, reducing OPEX, and supporting high-performance laser applications. This solution ensures precise, reliable control for demanding non-circular fiber production.

online extrusion

Nextrom’s polymer jacketing removes the need for a separate process step or dedicated extrusion line—cutting both CAPEX and OPEX. As the only proven online extruder on the market in specialty fiber draw, backed by the Rosendahl´s & Knill Gruppe’s deep extrusion expertise, it provides a more streamlined approach.

water free cooling

Seamless PI coating application with Nextrom’s water-free temperature control system. By using electrical cooling instead of water, this innovative solution reduces operational costs, maintenance requirements, and production risks. Delivering precise, reliable temperature management for PI coatings, it offers a straightforward, cost-effective way to produce high-quality specialty fibers.

How to increase precision & flexibility in specialty fiber draw production

with RFS draw furnace, tension measurement and

specialty fiber proof testing

furnace flexibility

The RFS furnace family spans an exceptional 10–100 mm preform diameter range, letting you draw everything from narrow canes to large‑core preforms without swapping equipment. By covering the full spectrum, you slash CAPEX, streamline changeovers, and keep your OFC20SF tower ready for any specialty‑fiber demand.

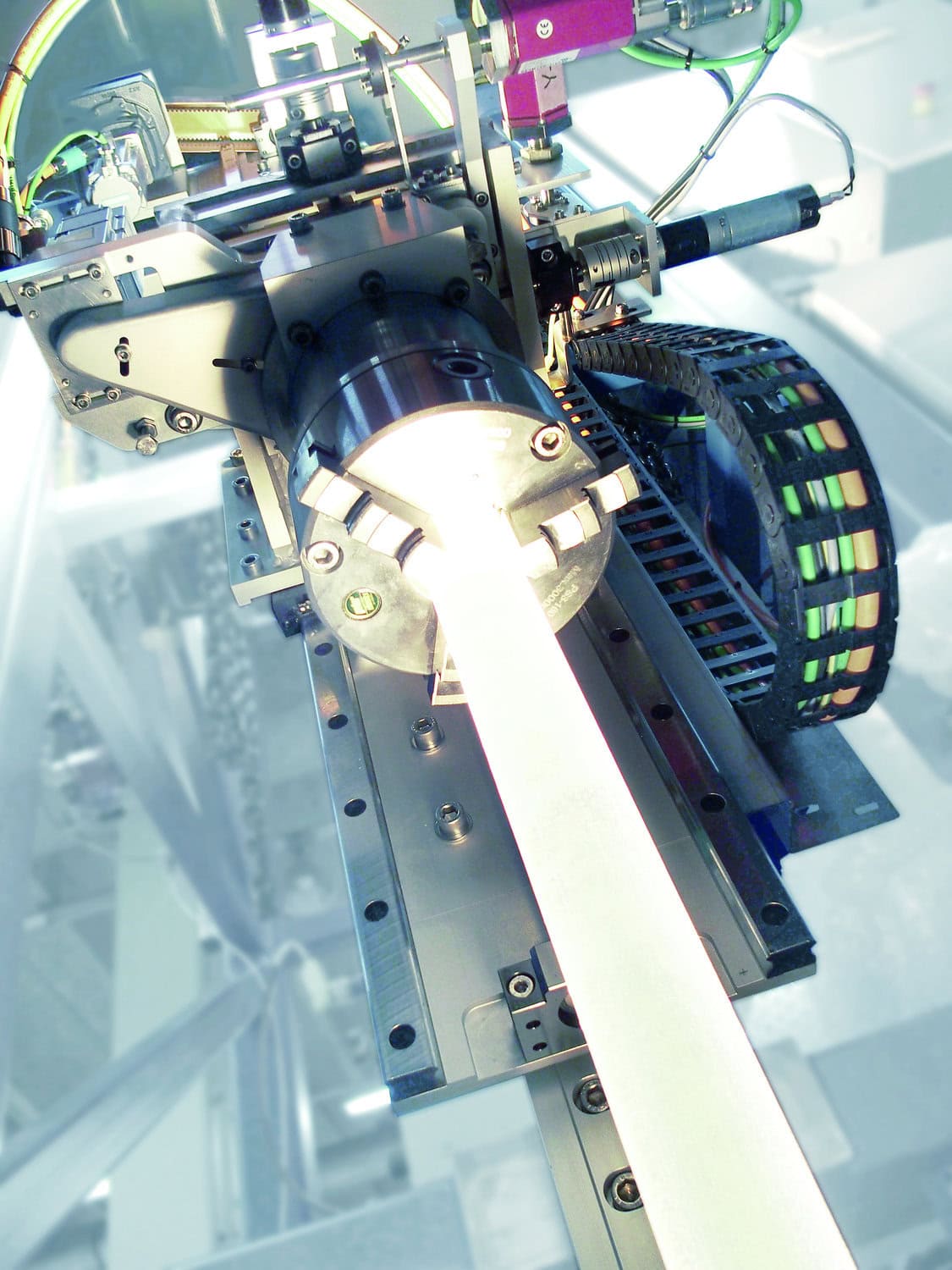

CTC tension measurement

Gain a new layer of process control for cane, tube, and capillary production. The CTC caterpillar capstan tension measurement captures draw tension in real time, giving operators actionable data to fine‑tune parameters on the fly. By spotting deviations instantly, you boost yield, cut scrap, and drive OPEX down—consistent specialty fiber with every run.

proof testing

Advanced proof testing solution purpose-built for the unique demands of specialty optical fibers. Whether handling hollow-core, photonic crystal, or doped fibers, these systems combine high-precision alignment, low-tension winding, and twist-minimizing design to protect delicate microstructures. This reduces fiber breakage, ensures consistent mechanical screening, and preserves critical optical performance.

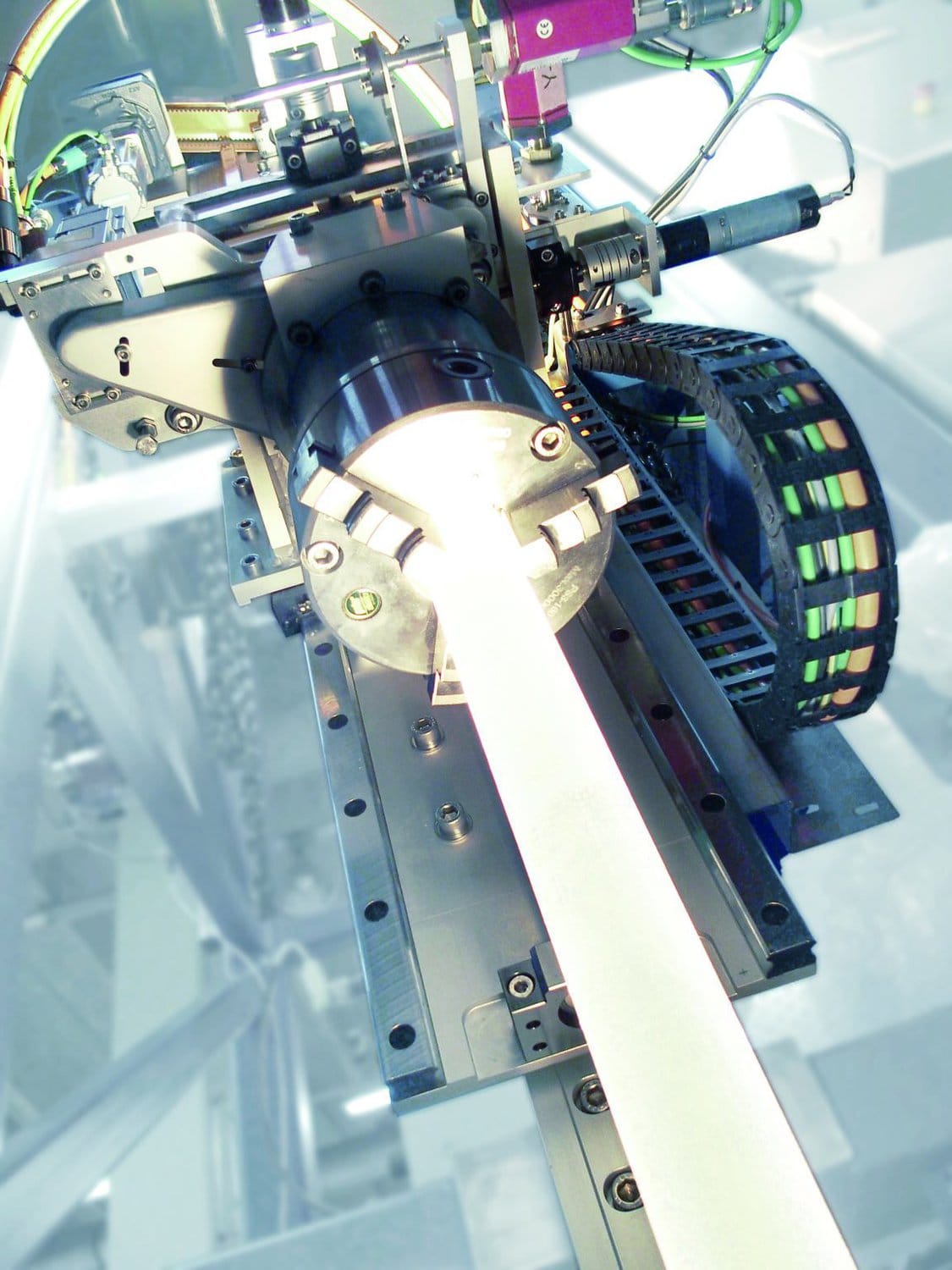

tension measurement system CTC

Tension Measurement System integrated into caterpillar capstan is an advanced solution designed to monitor and control the tension of canes & tubes during the drawing process in a specialty fiber production.

Directly measuring the tension within caterpillar capstan eliminates the need for expensive tension gauge or separate tension pulley. Furthermore, solution like this is essential for drawing capillaries and canes successfully when the product cannot be bent and non-contact measurement gauges cannot measure correctly.

By ensuring precise tension control by real-time tension monitoring the system enhances fiber quality, reduces breakage, and maintains uniformity. When integrated into a Nextrom draw line, a feedback loop is established, allowing for automatic adjustments to drawing parameters, further optimizing the production process.

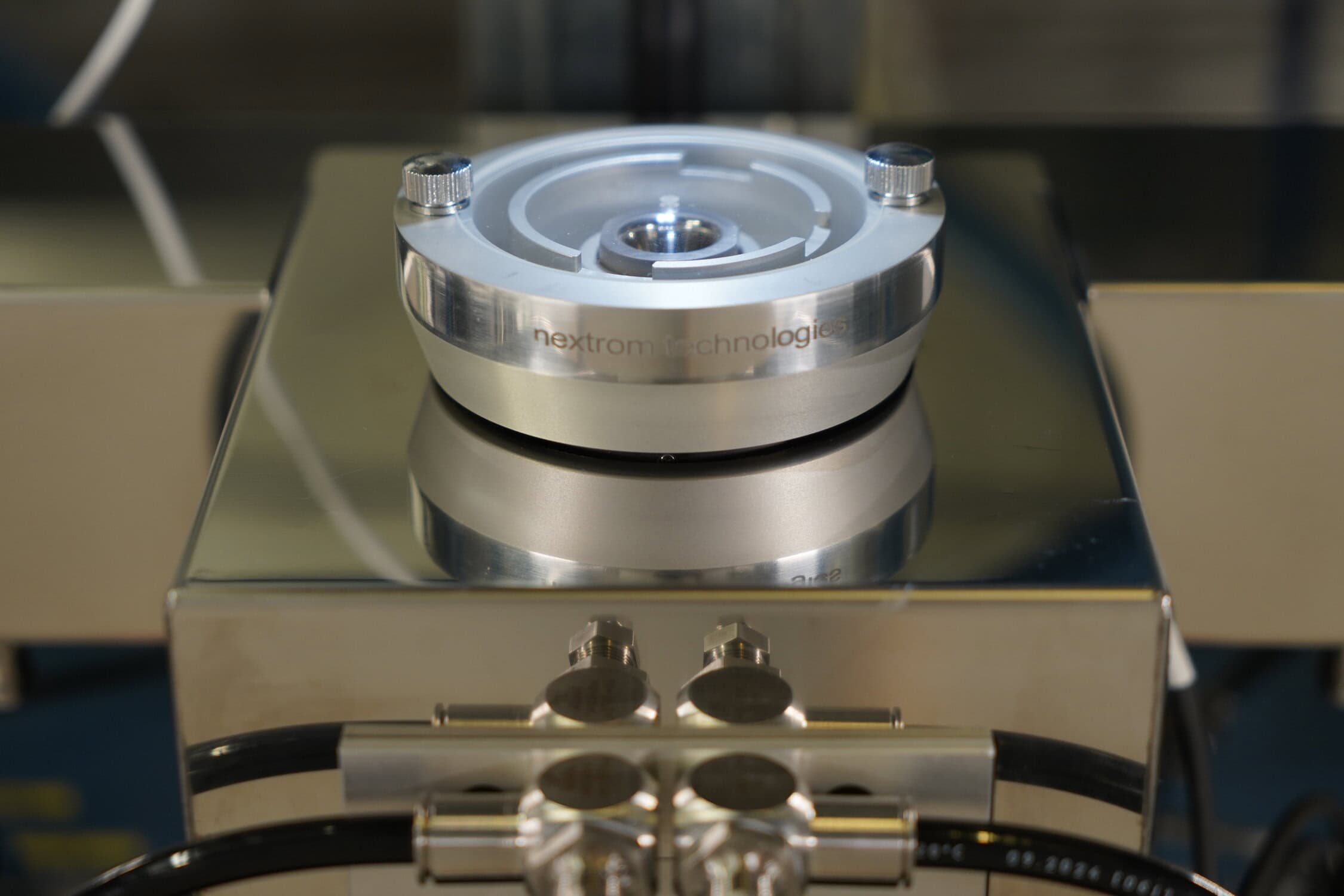

w-o-w coating applicator

wet-on-wet (W-O-W) coating applicator is purpose-built for specialty fiber production, ensuring uniform coating thickness and excellent concentricity. With precise alignment and stability, it minimizes contamination risk and delivers repeatable, high-quality results. Die change in minutes and tool-free cleaning for easy operation, reducing downtime and improving overall process efficiency.

nextrom's special experience

unmatched flexibility, unrivaled expertise

upgradability

Keep your draw tower at the cutting edge—today, tomorrow, and decades from now. Nextrom’s dedicated team upgrades even the oldest OFC20SF systems, integrating the latest hardware and software. Enjoy minimal downtime, sustained performance, and confidence that your technology will remain state‑of‑the‑art for years to come.

process knowledge

Rely on our dedicated experts—backed by years of combined specialty draw experience—to guide you through thorough commissioning and process training. Our tailored setup recommendations minimize tuning time and speed up your production ramp-up. With a proven global track record and hands-on industry know-how, we ensure you get into full-scale production faster, more efficiently, and with unwavering confidence.

references

We deliver proven know-how to jump-start your production, maintain top-tier quality, and preempt operational pitfalls. Industry leaders repeatedly rely on Nextrom—clear proof of our unwavering reliability and superior performance.

local support

Benefit from truly local teams across the US, China, India, and Europe—each offering quick response times, spare part availability, and support in your local language. With experienced engineers on-site, you’ll minimize downtime, optimize productivity, and have peace of mind knowing expert help is always within reach.

OFC 20 SF – Fiber Draw Tower

SFT – Specialty Fiber Take-up

Flexible production for wide selection of specialty fibers

SPF Specialty Preform Feeding

PSS Preform Spinning System

RFS Draw Furnace

Preforms up to 100 mm

Measurement devices:

Diameter, lump, tension

NCT Cooling Tube

Active cooling of the fiber

CTC Cane & Tube caterpillar capstan

ACA Single layer coating applicator

UV-cured or thermal coatings

UV-Curing (left) or Thermal Curing (right)

ACA Single layer coating applicator

UV-cured or thermal coatings

UV-Curing (left) or Thermal Curing (right)

Measurement devices:

Diameter, lump, tension

SFC – Specialty fiber capstan with

tension measurement

Speeds up to 700m/min

Multiple options for single and dual reel take-ups

range of fiber types

The Nextrom OFC 20SF Fiber Draw Tower supports production of an extensive range of specialty fiber types—including soft glass, silica, cane and capillary tubes, and advanced designs such as microstructured (HCF).

Single-mode

Multi-mode

- Hollow-core

Amplifier fiber

Laser fiber

Holey fiber

Chalcogenide fiber

- Polarization maintaining fibers

- Rare earth doped fibers

Features

Advanced temperature controller with ±1 °C stability at 2100 °C

Caterpillar capstan ensures low-stress, concentric pulling (optional tension measurement available)

Proven fiber diameter precision of ±0.1 µm

Real-time production monitoring via user-friendly line control system

Applicator cooling system for consistent coating

Compact footprint – available in single or dual-face layouts to optimize cleanroom space

Wide take-up options for various reel sizes, including Dual take-up option for continuous production with minimal downtime

Tailored-solutions to match your requirements:

Preform internal pressure/vacuum system

Preform rotating equipment

Gas purification (Ar/N₂)

Start-up and master capstans

Clean air system options

Online extrusion for coatings

High-Capacity Solutions:

RFS 100 Specialty Fiber Draw Furnace– Supports preforms up to 100 mm diameter

FCS – Active fiber cooling system for enhanced quality

NKP 450 – Dual take-up for continuous production and draw sampling

contact

get in

touch

with us