our telecom

fiber and preform

solutions

Nextrom provides solutions for all your needs regarding the telecom preform and optical fiber production.

We offer a comprehensive range of customizable and cutting-edge manufacturing solutions to serve the distinguished telecom fiber market.

From complete solutions for VAD Core and OVD Clad production to state-of-the art optical fiber draw towers. As a one-stop shop we enable you to produce high quality preforms and optical fibers for the Telecom optical fiber market.

With our tailor-made equipment you can maximize your production output from start to finish.

Nextrom’s manufacturing solutions for producing preforms and optical fibers for telecom fiber producers are widely used within the industry across the globe by the most prestigious fiber producers in the business.

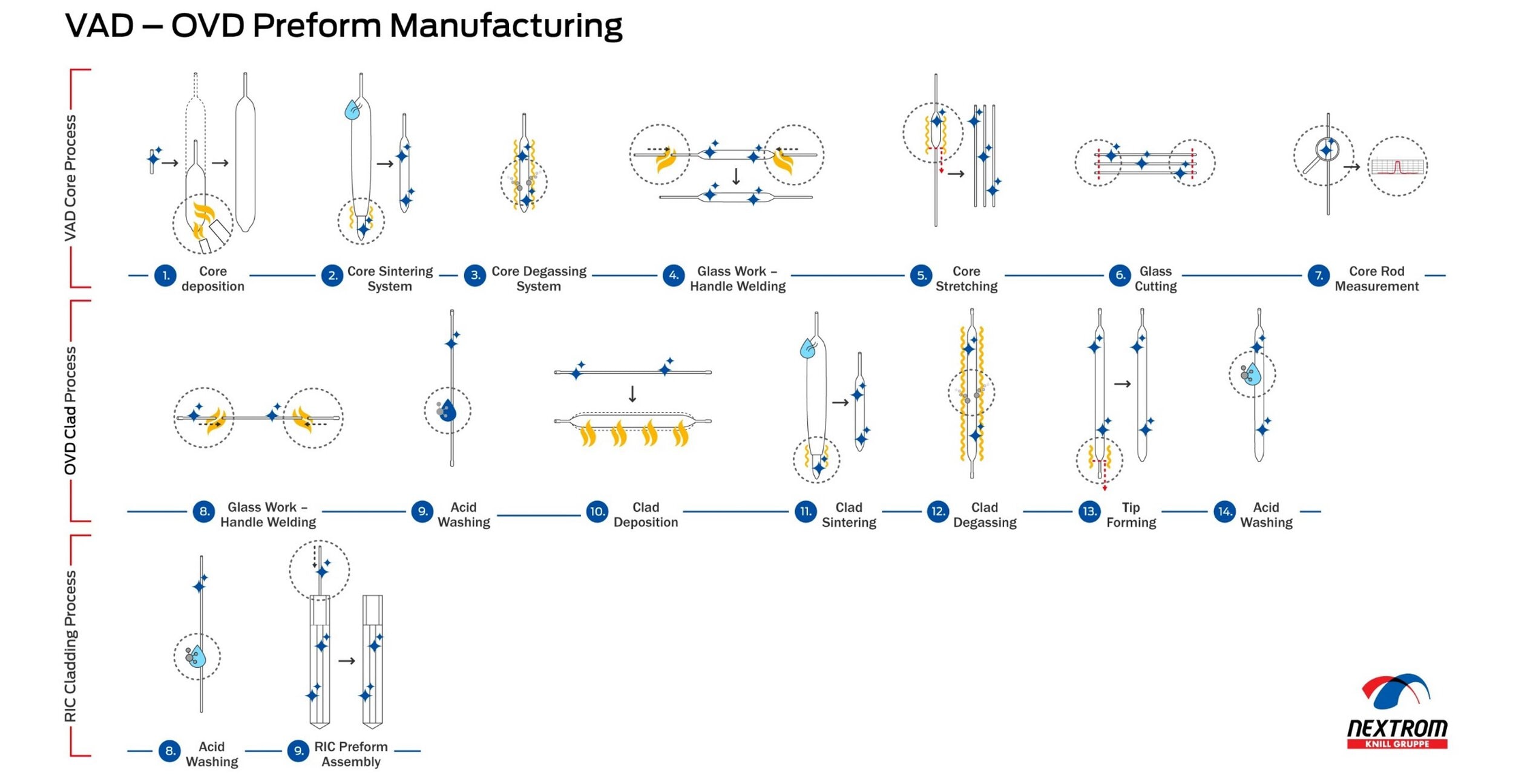

Preform Manufacturing

VAD Core & OVD Clad

Achieve perfection in optical preform production. Nextrom provides all necessary steps to manufacture high quality optical preforms. Achieve optimal results in fiber draw and in the quality of the optical fiber.

Nextrom offers two complementing process steps in manufacturing first-rate optical telecom preforms to draw the highest of quality optical fibers.

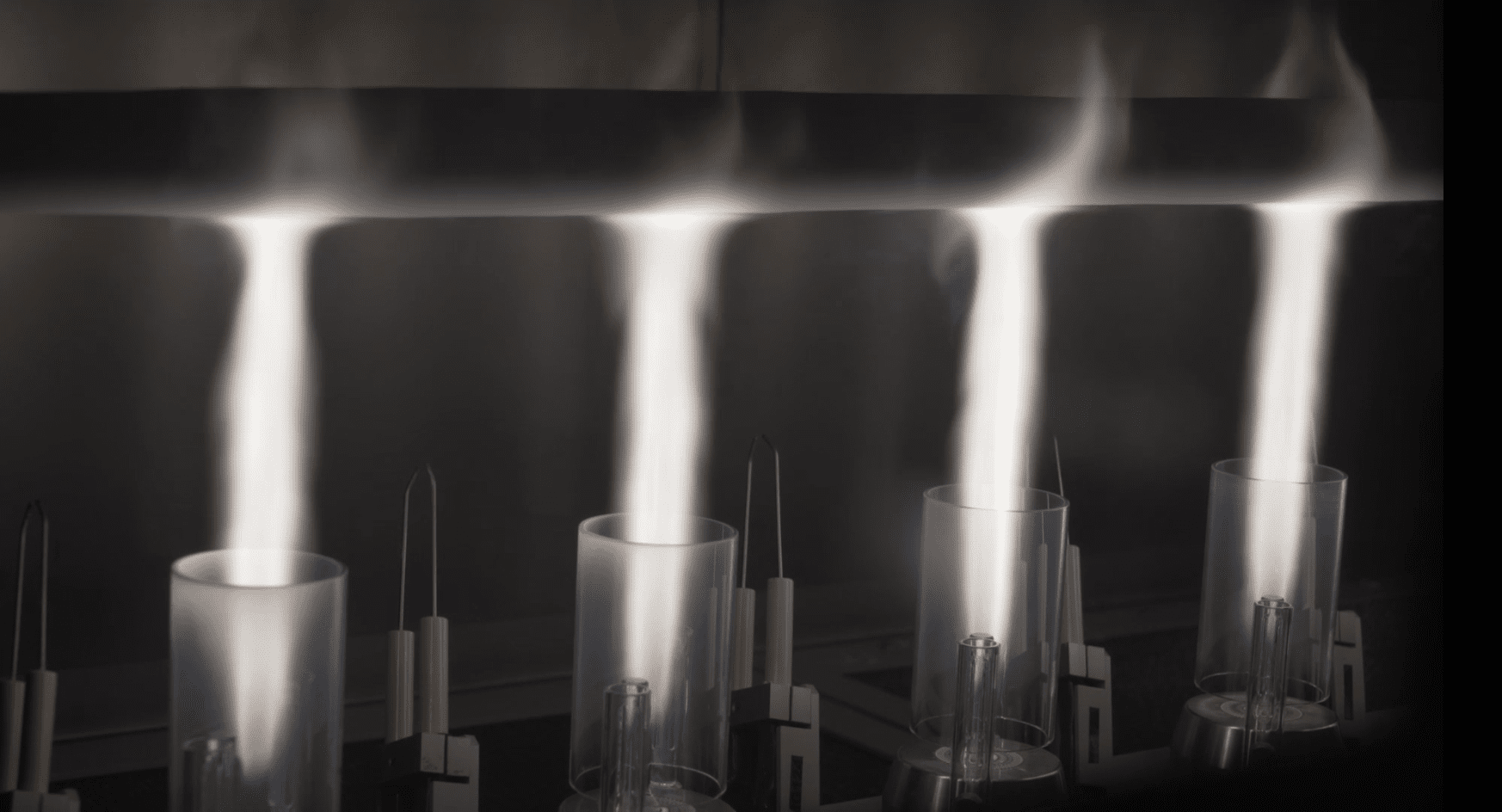

Vapor Axial Deposition (VAD)

A fiber preform production technique where core and cladding layers are simultaneously deposited as glass particles to form the fiber inner cladding and core structure of the preform.

Outside Vapor Deposition (OVD)

A process where the silica soot is deposited on the outer surface. Once enough layers are in place, the rod is removed, and the layers are then consolidated into a solid preform which can be drawn into optical fiber.

Telecom Fiber Draw Towers

High-speed fiber draw tower

The Nextrom OFC 20 fiber draw tower for Telecom optical fiber production is available with different furnaces and precise preform feeding solutions to produce high quality optical fibers for the Telecom market. We cater individual and specific needs for your flexible production of optical fiber.

High quality components and solutions in the Nextrom Fiber Draw Tower, tailor-made in Europe, guarantee excellent production conditions. This gives you the security of quality operation in short term and a strong reliability in long-term.

Always at the forefront of draw tower technology

- Continuous improvement

- Development and research programs

- For new and existing users

When producing telecom fibers, you can trust Nextrom’s manufacturing solutions like most prestigious fiber producers within the industry across the globe.

Boost your existing production lines performance by adding individual integral machines and components to your fiber draw or preform production line.

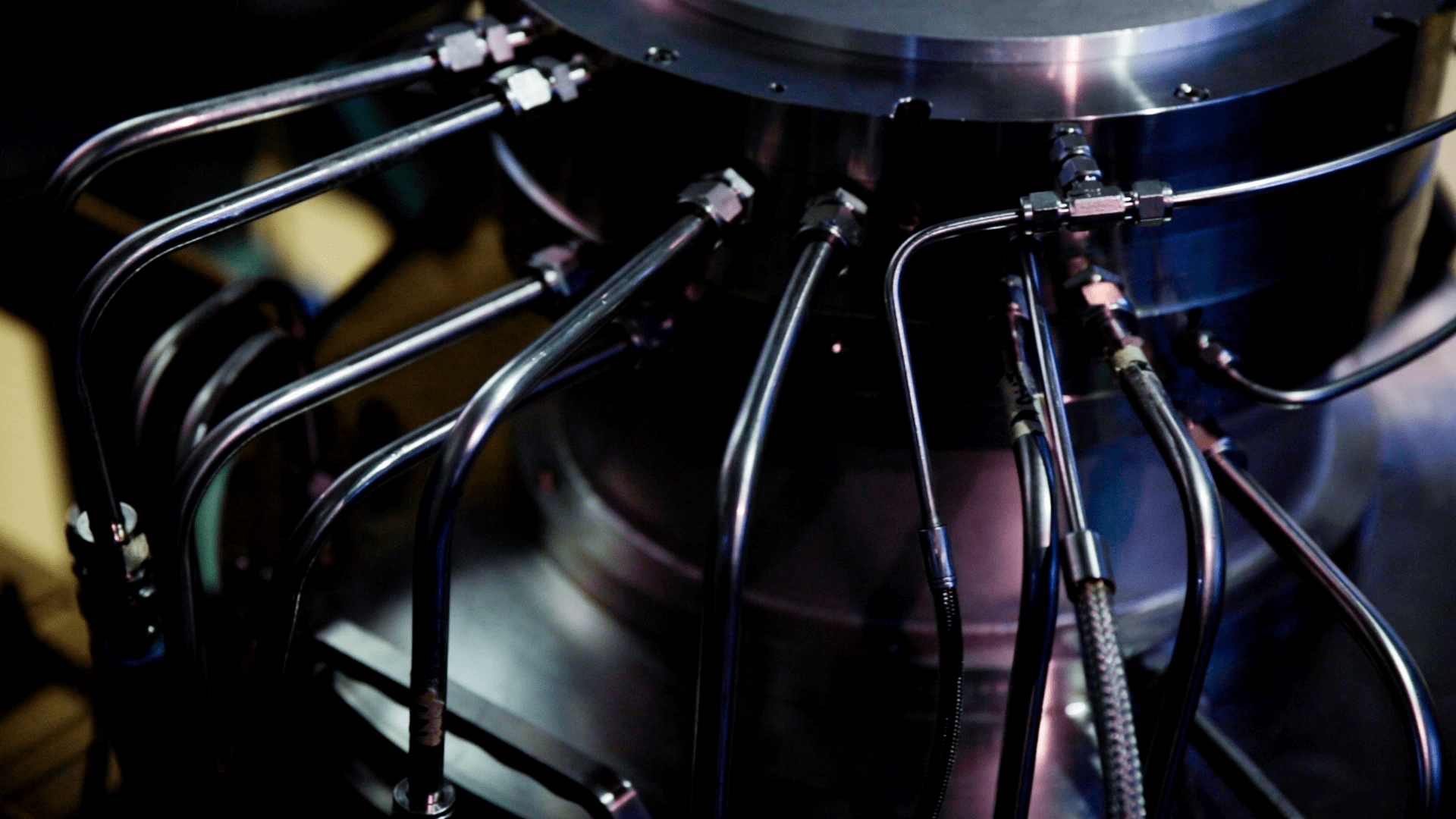

The Induction Furnace is designed for fast drawing of large diameter up to 230 mm optical fiber preforms. Induction technology results in a simpler graphite design which is robust, easy to change and guarantee long operating lifespan with proper operating procedures.

Dynamic iris provides sealing solution for uneven performs. It is designed for preforms with large outer diameter variation along the preform length. Sealing elements can be used continuously.

Nextrom offers multiple options to customize every furnace system to specific customer products and needs.

DFT 2500 Dual take-up is used to collect the drawn fiber onto large aluminum reels. These reels can each hold up to 1500 km of drawn fiber. Due to the weight of the spool (up to 100 kg), aluminum reels are a good alternative for commonly used plastic ones, providing the required accuracy and durability without adding more weight. A specially designed reel cart can be ordered along with the DFT 2500 to assist with the loading, un-loading and moving of the reels. Automatic change over at full line speed allows a continuous drawing process and minimizes the scrap with long fiber lengths.

The faster the draw is, the better DFT 2500 operates. DFT 2500 meets and exceeds the needed take-up requirements of today´s market. With the help of our customers, Nextrom is always on the lookout on how we can make their production conditions better and more suitable for the end user.

Nextrom’s OFC 02 NDS deuterium treatment system treats Low Water Peak Fibers (ITU-G.652C) with deuterium gas. The properties in the optical fiber stay intact in operation of the optical fiber. The deuterium treatment ensures that OH-related attenuation does not rise during the lifetime of the optical fiber.

Additionally, a Hydrogen Ageing Test option can be added into the Deuterium System. Hydrogen ageing is done to determine the optical fiber’s hydrogen sensitivity. Attenuation levels of the optical fiber is then measured to determine if there are permanent attenuation increases caused by hydrogen.

NDS is a modular system, which can easily be tailored for different treatment capacities. It comes in 12 different standard configurations, each with different treatment capacity.

To meet the requirements of Telecom optical fiber properties, Nextrom offers three different solutions for the proof-testing process of your optical fibers.

OFC 55 Coloring & Proof Testing Line with Automatic Reel Change

An automated tandem line that combines both coloring and proof-testing processes for a faster and for more cost-efficient results. Also, by combining these processes there are valuable floorspace savings in production facilities.

OFC 30 Proof Testing Line with Automatic Reel Change

Our proof testing and rewinding line. We designed it to be highly productive for fiber manufacturers who require high capacity with low labor cost.

OFC 35 Proof testing and rewinding line

An axial tension proof testing system especially designed for Telecom fibers. With extended tension ranges for tensile testing and proof testing, it uses integrated bending wheels to test fiber strength in 8 directions. It is a highly accurate system where the resolution is maintained with multiple tension gauges for different fiber ranges. In all our solutions we pay special attention to

- high-quality take-ups and pay-offs

- flexible configurations

- quick set-up

- easy operation and maintenance

You can reach a top performance level by efficient servo motors, high accuracy tension sensors, and purpose to special design dancer which guarantee effective winding at high speeds. You can also key a cutting plan into the unit so that it stops when you reach the desired length.

Ergonomic and safety focus

We put a lot of effort in ergonomics and ease of use as well as on safety. The operator only needs to change full reels in the pay-off and empty reels in the take-up. It is a system that is easy to handle, and it fulfills international proof testing standards.

Nextrom’s solutions to Proof test telecom optical fibers are widely used across the globe by the most prestigious fiber producers within the industry.

As the optical fiber count is ever increasing in optical fiber cables, it´s important to differentiate your optical fibers by using Nextrom´s high-speed and reliable solutions for coloring.

Nextrom offers advanced high-speed coloring lines along with, automated tandem line that combines both coloring and proof-testing processes for faster and for more cost-efficient results. Also, by combining these processes there are valuable floorspace savings in production facilities.

With our Nextrom equipment, you can color all types of fibers from single mode optical fiber to multimode fibers as well as specialty optical fibers. We can also add solutions for ring marking and upcoating to your line.

All the coloring parameters are controlled, which provides flexible and easy-to-use coloring for the operator. The pressurized coloring system can handle all types of inks.

Nextrom’s solutions of coloring optical fibers are widely used across the globe by the most prestigious fiber producers within the industry.

Rosendahl Nextrom´s OFC 21 High Speed Ribbon Line offers advanced cutting edge technology for the Ribbon process. Long term process development together with proven production technology enables reliable and flexible ribbon production.

OFC 21 is a compact system that enables the user to take advantage of the latest developments of optical fiber coating and fiber handling technology. High quality ribbons with accurate dimensions and excellent optical properties are manufactured with this new advanced, modular system.

contact

get in

touch

with us

From first contact onwards, we provide customized high quality solutions and personal support to ensure total customer satisfaction.