technology space

In a total we have 3 development centers where our machines are assembled, commissioned and pre-acceptance tested.

In the field of lead-acid battery manufacturing we have two halls which are solely dedicated to our lead-acid machines and lines. These areas are subject to strict safety precautions and may only be entered with appropriate protective equipment, such as safetey shoes, etc.

In general safetey is a major concern for us – but when it comes to producing lithium-ion battery systems it is an absolute must. Therefore we built LIB development center.

LIB development center

Exclusive space for innovation and development.

We focus on a highly flexible production solution without sacrificing the cost-effectiveness of flow production and with the ability to be easily scalable. A core element is our R&D&I centre to carry out process and production developments to achieve a new, agile, automated manufacturing solution.

A core element is our development centre to carry out process and production developments to reach a new agile automated manufacturing solution.

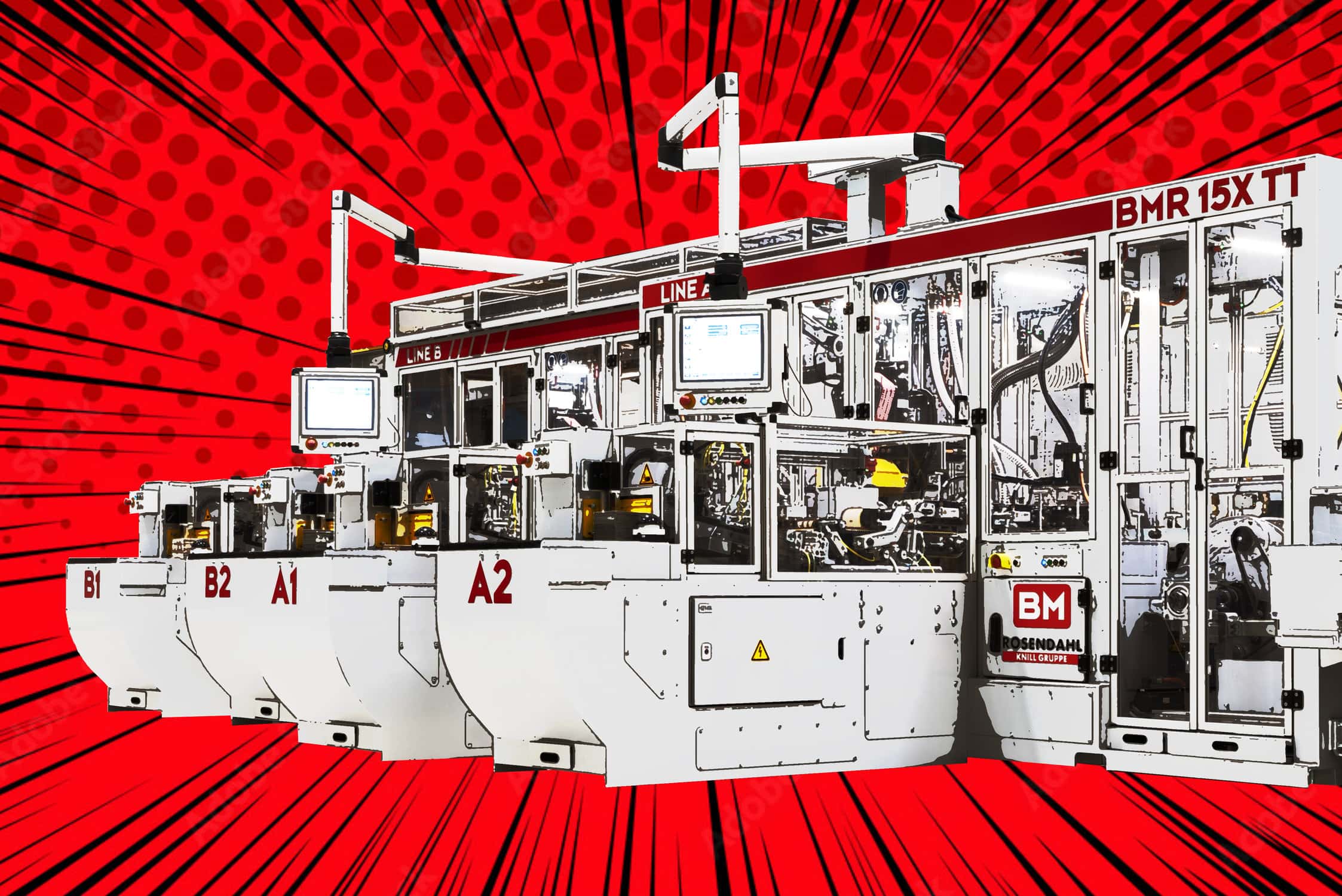

Currently in display:

laboratory

In the BMe Laboratory welding connection samples can be tested. Different qualification tests can be run in a short time.

We are offering a tensile testing machine with capacities of up to 10 kN, electric resistance testing equipment and everything for macro and microscopic metallurgy analysis.

Thanks to our expertise in laser welding and welding analysis, we have enabled the development of an optimized and stable welding processes for your welding connection design.

contact

get in

touch

with us