precision equipment for MCVD preforms

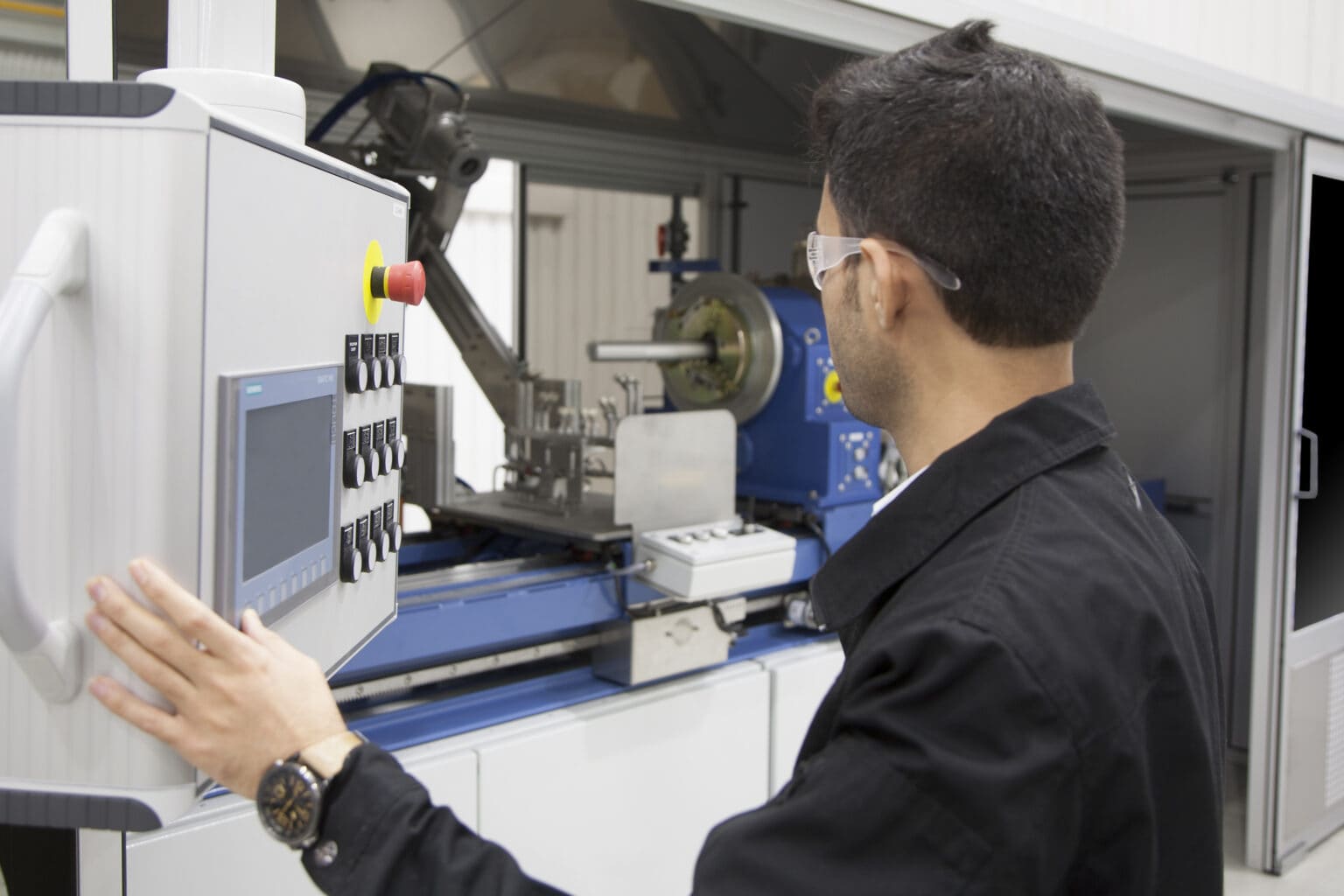

Embrace excellence with Nextrom´s OFC 12 MCVD System

Modified Chemical Vapor Deposition (MCVD) is a well-known and widely used method for the fabrication of high-quality optical fiber preforms.

The Nextrom OFC 12 MCVD system offers a wide variety of options and configurations to create the perfect preform for your needs.

With hundreds of units delivered since 1990, it’s the industry’s most widely used MCVD solution. Metallic piping ensures exceptional purity during the MCVD process and helps to achieve exceptional refractive index stability. Expect high-quality, repeatable results for your preform production.

Specifications and functionalities are defined together to meet even the toughest demands. It´s perfect for industries and ideal for universities and industrial research labs looking to push the boundaries of optical fiber technology.

unmatched accuracy

Achieve unmatched preform accuracy with our best-in-class Bow Control System—designed to straighten preforms automatically.

purest

materials

By eliminating the need for extra nitrogen shielding with metal piping you´ll significantly reduce contamination risks and operational costs, while delivering a cleaner, purer product.

minimal

variation

thanks to our precise deposition temperature and pressure control, you can achieve exceptional refractive index in the cladding and core.

trusted

repeatability

By delivering reliable results, you’ll reduce process time, boost yield, and cut operating expenses. Nextrom is trusted by industry leaders worldwide for its high repeatability and stable performance.

advantages of Nextrom MCVD equipment

efficiency through process stability & product control

unmatched accuracy

Achieve unmatched preform accuracy with our best-in-class Bow Control System—designed to straighten preforms automatically. By minimizing manual intervention and ensuring precise concentricity, you’ll spend less time on corrections, reduce scrap, and optimize overall yield. The result – Lower operating expenses, higher profit, and consistently superior specialty preform quality.

pure materials

Experience the benefits of a completely stainless steel piping system with an electro-polished finish, engineered for unmatched leak tightness. By eliminating the need for extra nitrogen shielding, you’ll significantly reduce contamination risks and operational costs, while delivering a cleaner, purer product. This robust, industrial-grade design supports a wide range of production requirements, maximizing both flexibility and productivity.

minimal variation

Achieve near perfect refractive index, thanks to our precise control of deposition temperature and pressure. This advanced approach delivers minimal index variation in the cladding and core, resulting in consistent geometry, higher yields, and top-quality preforms throughout.

trusted repeatability

We are trusted by by industry leaders worldwide for its high repeatability and stable performance. These ensures consistent preform properties, preform after preform, thanks to rigorous process controls and decades of industry validation. By delivering the same reliable results each time, you’ll reduce process time, boost yield, and cut operating expenses.

How to increase the productivity & yield in specialty preform production

with automatic tube preparation, automatic material fill, advanced soot box, and vapor phase doping

automatic tube preparation

Increase production flexibility and yield with the Automatic Tube Preparation System, which lets you quickly adjust tube dimensions to your exact needs. By customizing tubes instead of stocking specific size tube you gain supplier independence, and streamline your supply chain — cutting operating expenses.

automatic

material fill

Boost repeatability and efficiency with automatic refilling. By maintaining consistent bubbler fill levels, process repeatability is increased and with automatic refilling, there is no downtime due to material vessel changes.

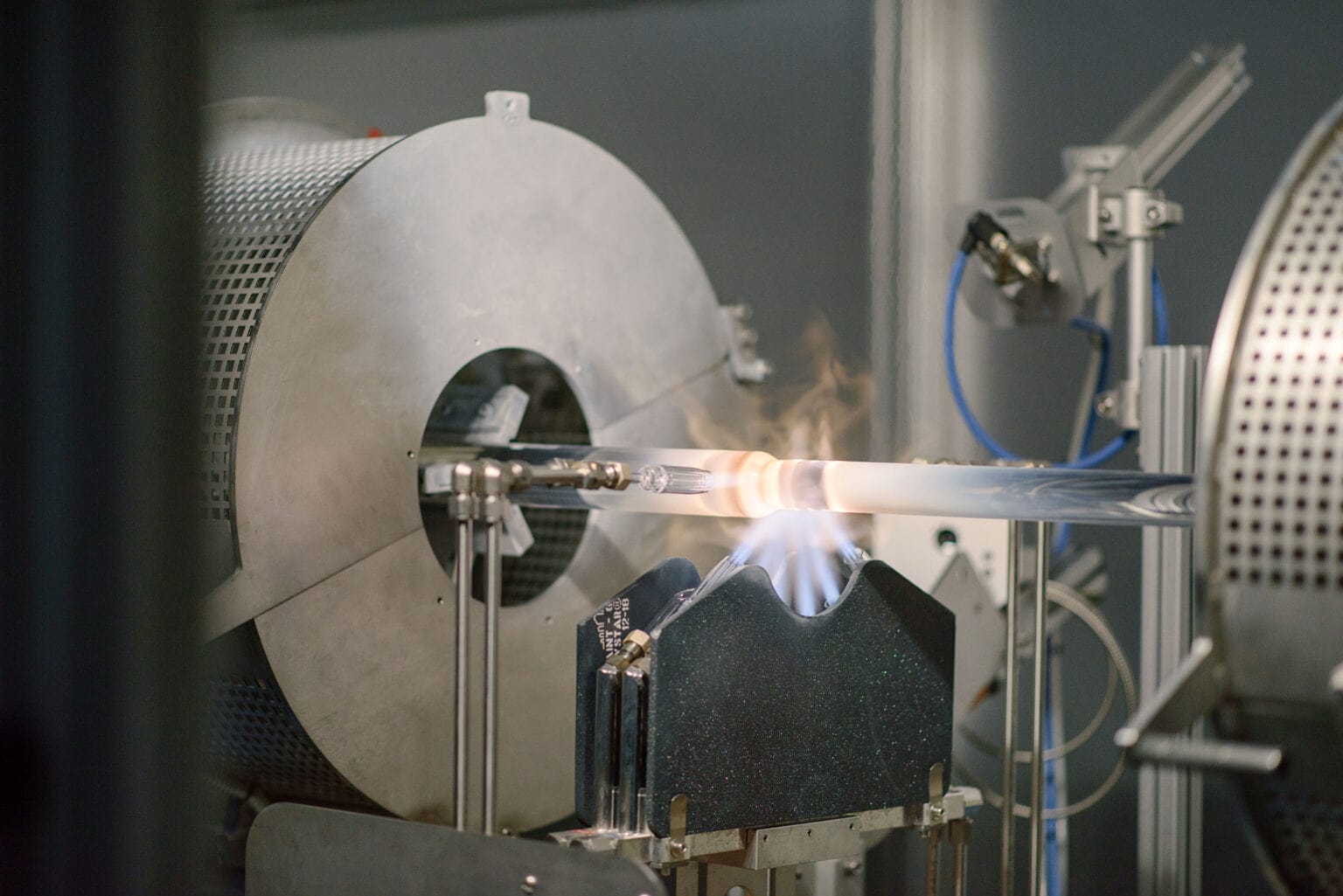

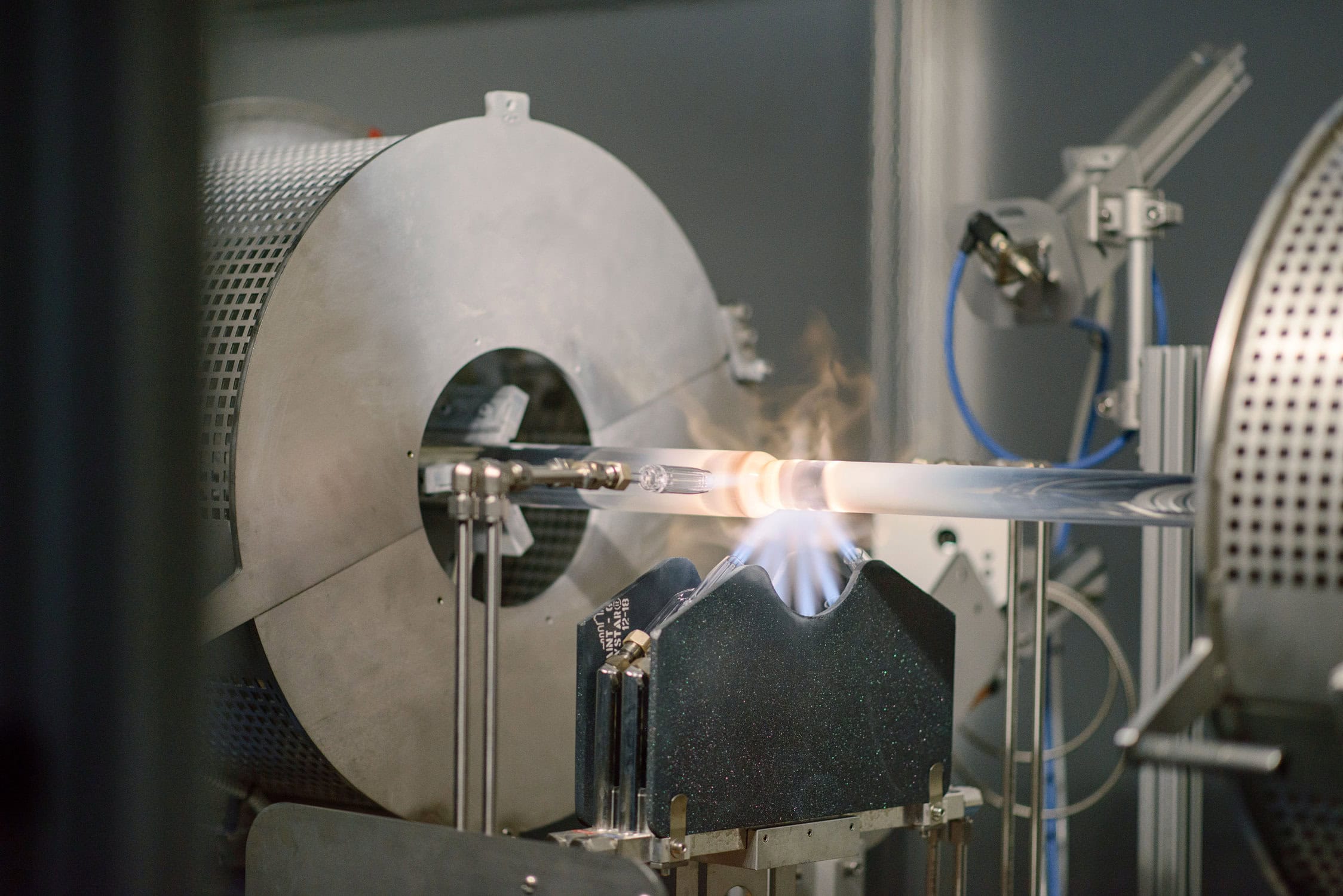

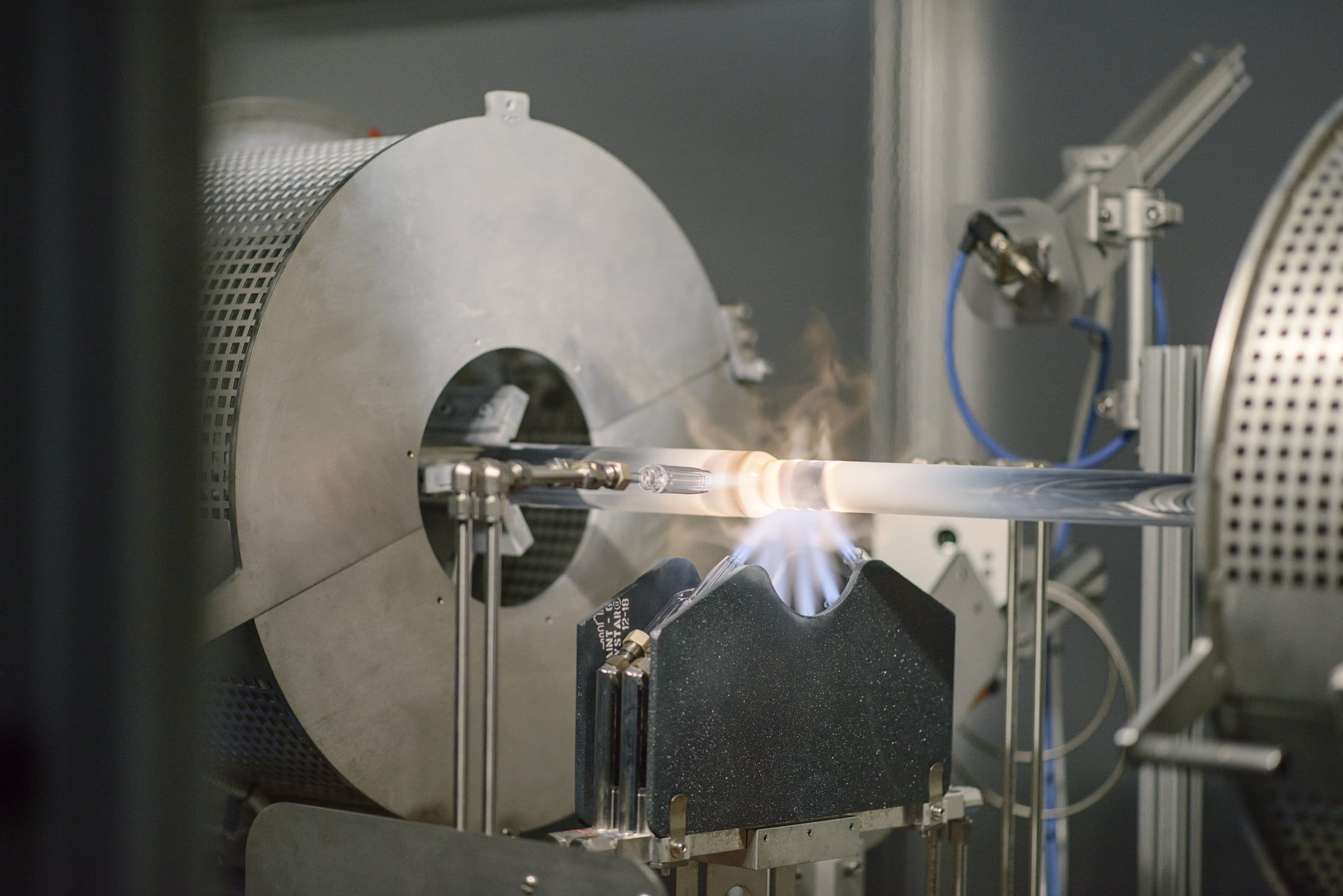

advanced

soot box

Ensures exceptional purity and precise control of silica soot deposition during preform manufacturing. Its advanced design effectively minimizes contamination, leading to consistent quality and superior optical fiber performance with reduced nitrogen consumption. Allowing operators to spend less time on maintenance and more time producing consistent, high-quality preforms.

vapor phase doping system (NHS)

Nextrom’s Vapor Phase Doping System (NHS) is specially engineered for precise handling of low vapor pressure dopants such as Al, Er, and Yb. Fully integrated with the MCVD system, it accurately delivers rare-earth solutions and aluminium chloride using helium as an inert carrier gas. With precise temperature and mass flow control, it ensures exceptional uniformity, repeatability, and ease of operation.

nextrom's special experience

unmatched durability, unrivaled expertise

durability

OFC 12 MCVD Systems are built to last for decades – due to our MCVD system’s uncompromising build quality. This proven design significantly reduces downtime, maintenance, and reinvestment costs, cutting both CAPEX and OPEX over its extended service life. With many of our systems still running strong after 25+ years, you can rely on it for unmatched reliability, consistent output, and higher profitability.

process knowledge

Rely on our dedicated experts—backed by over 40 years of MCVD experience—to guide you through thorough commissioning and process training. Our tailored setup recommendations minimize tuning time and speed up your production ramp-up. With a proven global track record and hands-on industry know-how, we ensure you get into full-scale production faster, more efficiently, and with unwavering confidence.

references

Leverage our unmatched MCVD expertise—backed by 40+ years in the market and the largest installed base in the laser industry. With majority of China’s laser fibers produced on Nextrom equipment, we deliver proven know-how to jump-start your production, maintain top-tier quality, and preempt operational pitfalls. Industry leaders repeatedly rely on Nextrom—clear proof of our unwavering reliability and superior performance.

local support

Benefit from truly local teams across the US, China, India, and Europe—each offering quick response times, spare part availability, and support in your local language. With experienced MCVD engineers on-site, you’ll minimize downtime, optimize productivity, and have peace of mind knowing expert help is always within reach.

precision equipment for MCVD preforms

OFC 15 – Glass Working Lathe

High precision glass working

Working length up to 3000 mm

OFC 12 MCVD – Modified Chemical Vapor Deposition

Reliable and repeatable specialty fiber production

Key features

Advanced Control System

The state of the art process monitoring and controlling enables the most complex recipes for production of the widest product range and optimizes preform yields.

Advanced Gas Flow Control

Precision gas flow management ensures the perfect blend for accurate doping and layer characteristics.

Exceptional Layer Uniformity

With advanced control mechanisms, achieve uniform deposition ensuring impeccable quality and consistency.

Durable and reliable

Crafted from the finest materials, our MCVD system is built to withstand rigorous production schedules, ensuring longevity and reliability.

additional equipment

| product | description |

|---|---|

| Line scanner: | Displays the temperature profile of the hot zone, enabling precise analysis and control of deposition characteristics. |

| FCVD Furnace | FCVD Furnace instead of or in addition to the H2/O2-burner. 50 % reduction in collapsing time with FCVD furnace. Reduced production costs, increased productivity and higher fiber quality (LWPF) are examples of the advantages which are achieved with this furnace |

Glass-working, sleeving, and collapsing lathes:

Specifically designed to complement MCVD process in specialty preform production.

Lathes are supplied with all the instrumentation needed according to customer specific needs for high quality glass-working, sleeving or for collapsing purposes and are equipped with special burners for optimal results.

| product | description |

|---|---|

| horizontal glass-working and sleeving lathe system – OFC 15 | used for glass and preform processing in specialty fiber production. The lathe is suitable for various glass-working operations as well as for fire polishing and tube sleeving. |

| Collapsing Lathe | used for collapsing process. Once deposition phase is complete, the preform must be collapsed into a solid rod/preform before it can be drawn into specialty fiber. |

nextrom offers specialty fiber equipment for these specialty products

- ITU-T G 651 graded index multimode fibers

- ITU-T G 652D single mode low water peak fibers

- ITU-T G 655 non zero dispersion shifted fibers (NZDS)

- rare earth doped fibers

- polarization maintaining fibers (Panda)

- select cut-off fibers

- step index multimode fibers

- boron rods for PM fibers

- etc.

contact

get in

touch

with us