plasma chemical vapor deposition (PCVD) system for specialty preforms

shaping the future of technology - today

precision equipment for PCVD preforms

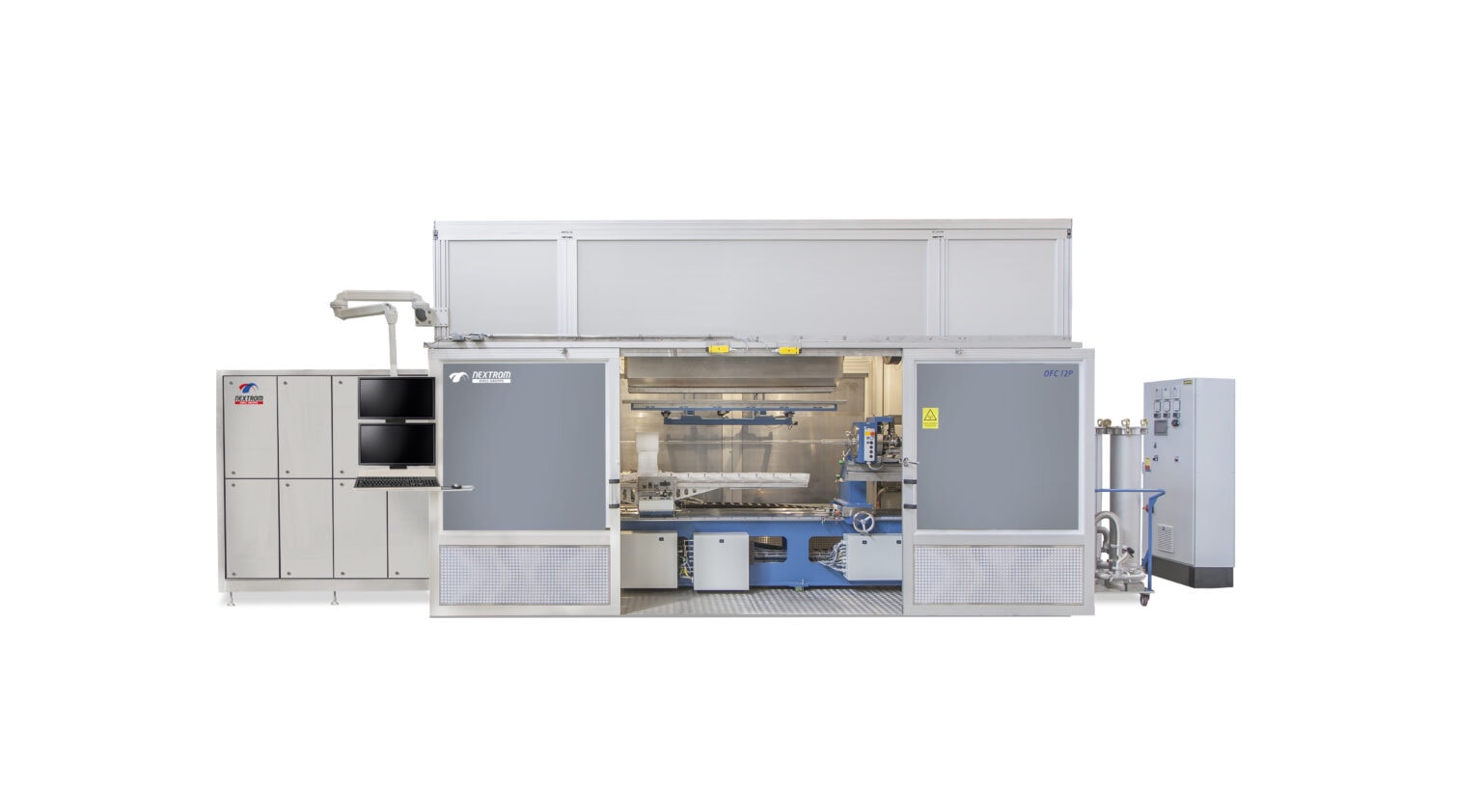

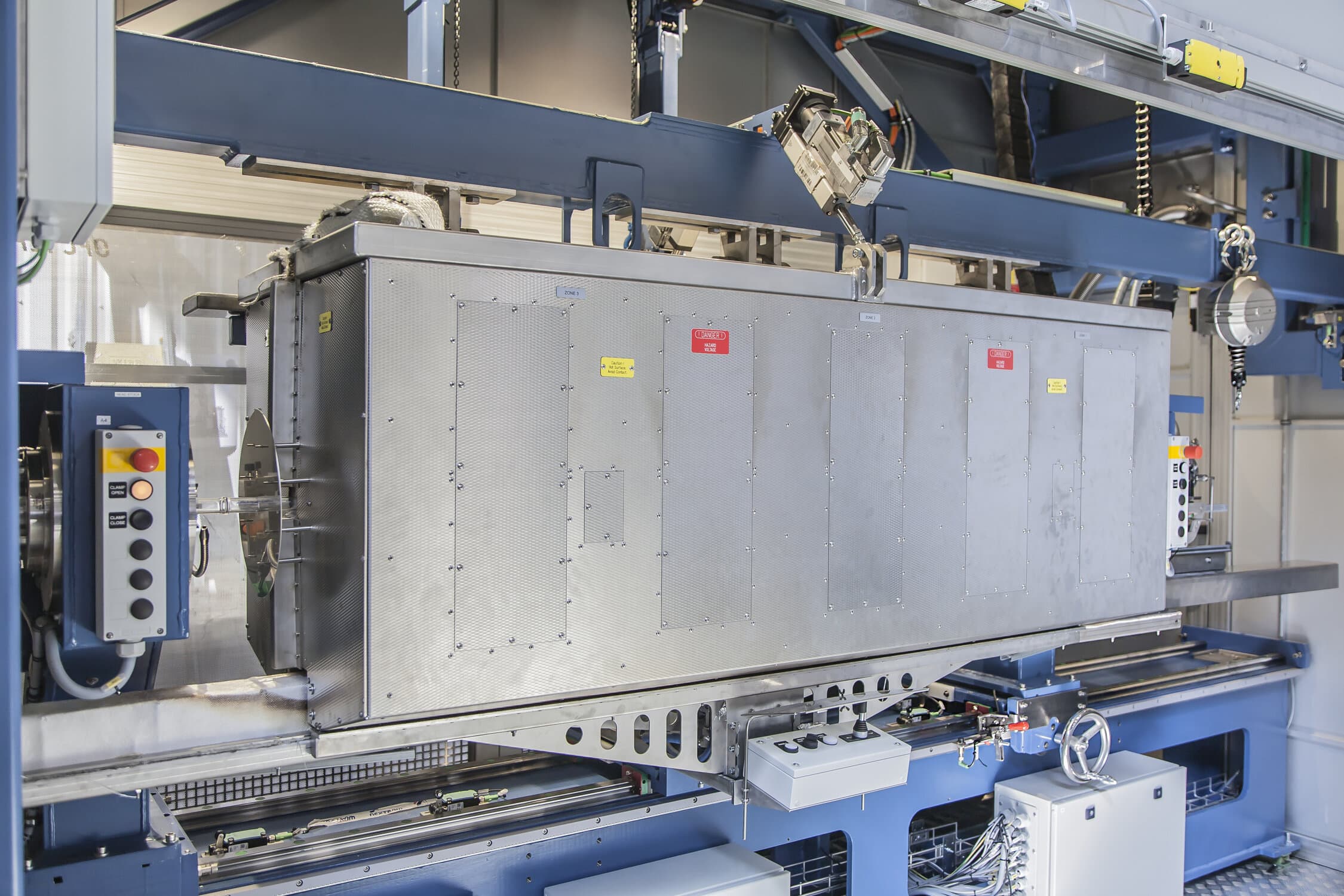

OFC 11 PCVD System – Precision, Purity, and Performance

Nextrom’s OFC 11 Plasma Chemical Vapor Deposition (PCVD) system represents the cutting edge of manufacturing technology for specialty fiber preforms.

As a provider of advanced production solutions – the OFC 11 enables fiber manufacturers to meet stringent demands of modern optical fiber applications—including high-power lasers, precise sensing devices, and complex telecommunications fibers.

Offering unparalleled refractive index control and exceptional layer purity, the OFC 11 sets new benchmarks for manufacturing quality and reliability.

Specifications and functionalities are defined together to meet even the toughest demands. It´s perfect for industries and ideal for universities and industrial research labs looking to push the boundaries of optical fiber technology.

advantages of Nextrom PCVD equipment

unparalleled refractive index control, exceptional layer purity, and scalable production

Superior Refractive Index Precision

Achieve unmatched precision in refractive index profiling, allowing manufacturers to create fibers with highly specific and complex optical characteristics. PCVD's fine-layer deposition and trenching capabilities enable precise tailoring of single-mode, multi-mode, and specialty fiber profiles for superior application performance.

Exceptional Layer Purity

Advanced design ensures ultra-pure layer deposition, significantly reducing defects and impurities. This results in enhanced fiber performance, higher strength, reduced signal loss, and improved overall reliability of the finished product.

Effiency

With over 95% collection efficiency

—

the OFC 11 ensures that nearly all introduced materials are effectively utilized in the preform. This results in higher yield per batch, reduced consumption of expensive raw materials, and less waste handling. For manufacturers, this means not only lower operational costs but also increased throughput, better resource efficiency, and a more sustainable production.

how to increase the productivity & yield in specialty preform production

with ferro-fluidic rotary joints, flexible gas configurations, and advanced process control

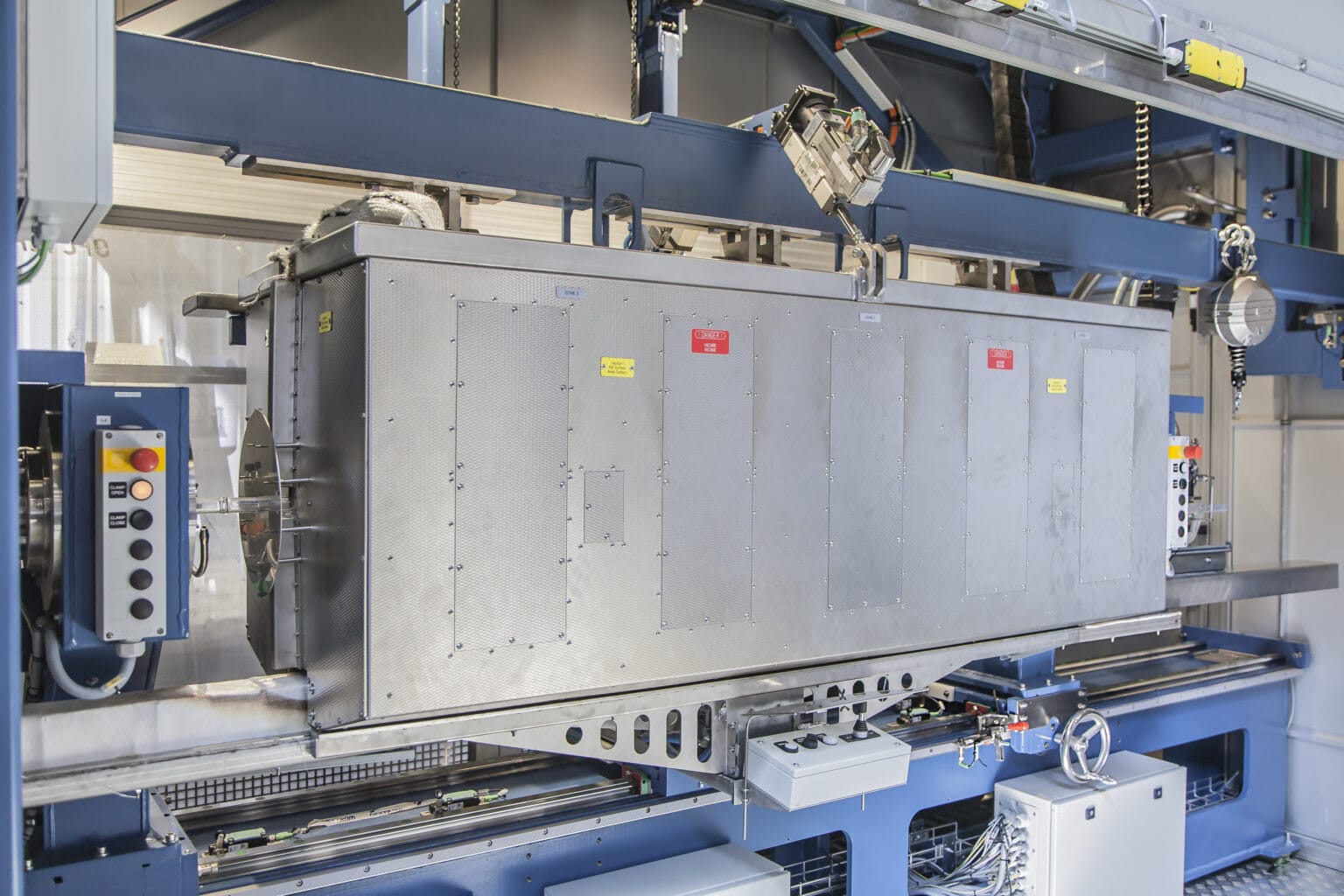

ferro-fluidic rotary joints

Provides exceptional leak-tightness and smooth, continuous rotation of the deposition tube under extreme vacuum and high-temperature conditions. These joints reduce the need for mechanical maintenance and minimize production interruptions, making them essential for high-throughput operations. Their ability to maintain stability ensures consistent layer formation during long deposition cycles.

gas configuration

Allow users to rapidly switch between gas types and flow profiles to accommodate different fiber designs and doping requirements. This flexibility reduces setup time, simplifies recipe changes, and supports the production of a broad range of specialty fibers without hardware reconfiguration.

process control and data logging

comprehensive monitoring of all key process parameters including gas flow, plasma power, and internal pressure. Real-time feedback enables immediate adjustments, reducing scrap rates and ensuring tighter process control. Historical data logging also supports quality assurance, traceability, and continuous process improvement.

nextrom's special experience in specialty fiber preform equipment

unmatched durability, unrivaled expertise

durability

OFC 11 PCVD Systems are built to last – due to our PCVD system’s uncompromising build quality. This proven design significantly reduces downtime, maintenance, and reinvestment costs, cutting both CAPEX and OPEX over its extended service life. You can rely on it for unmatched reliability, consistent output, and higher profitability.

process knowledge

Rely on our dedicated experts—to guide you through thorough commissioning and process training. Our tailored setup recommendations minimize tuning time and speed up your production ramp-up. With a proven global track record and hands-on industry know-how, we ensure you get into full-scale production faster, more efficiently, and with unwavering confidence.

local support

Benefit from truly local teams across the US, China, India, and Europe—each offering quick response times, spare part availability, and support in your local language. With experienced PCVD engineers on-site, you’ll minimize downtime, optimize productivity, and have peace of mind knowing expert help is always within reach.

precision equipment for PCVD preforms

OFC 11 PCVD – Plasma Chemical Vapor Deposition

Preforms with high accuracy index profiles

High numerical aperture and doping levels

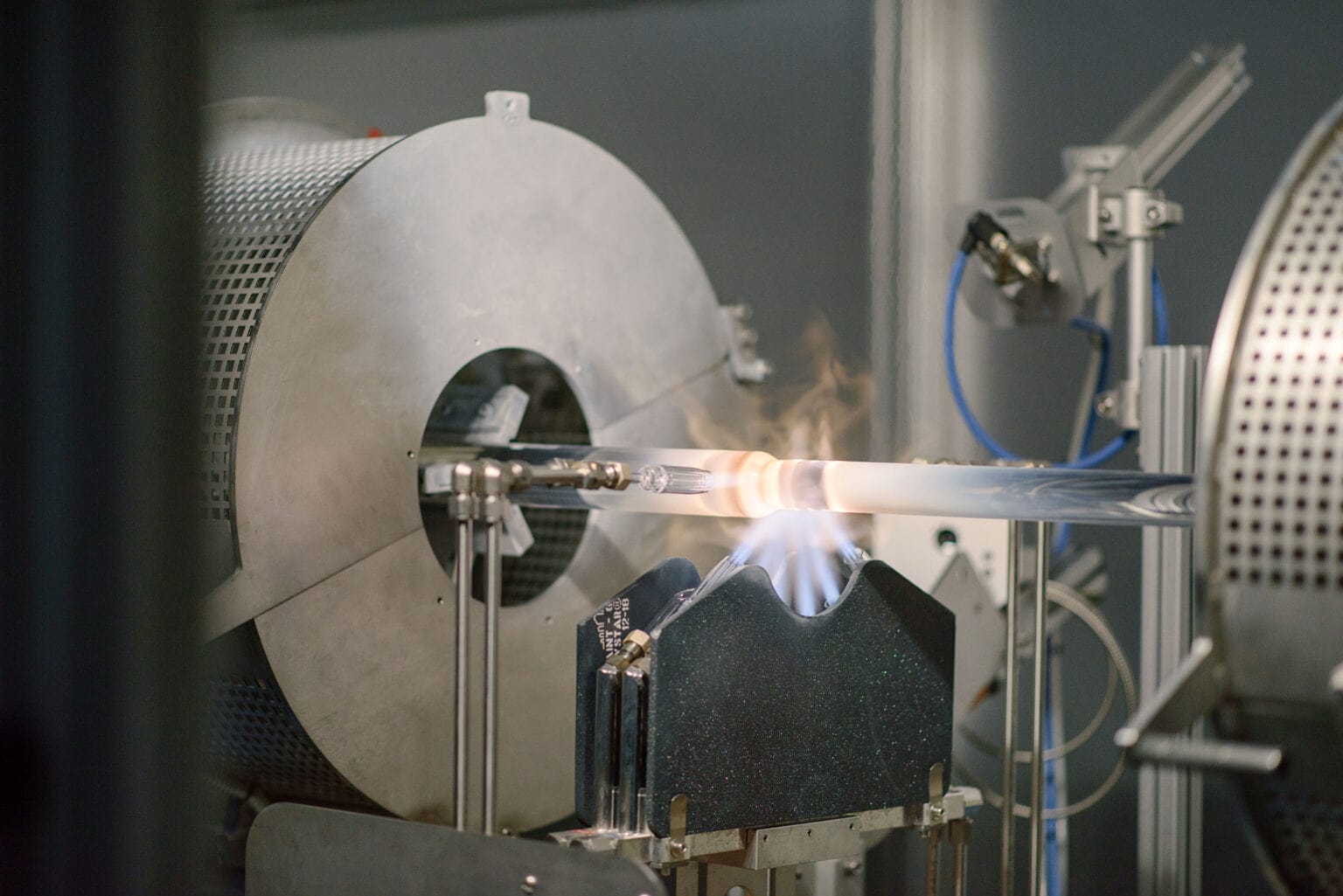

Collapsing Lathe

Faster and more efficient collapsing with furnace

PCVD key features

Repeatable and consistent results:

- Fine layers (Multimode fibers)

- Deeper down doping (trenching) for single mode or specialty fibers

- Over 95 % collection efficiency

Superior Refractive Index Control: Achieve unmatched control over the refractive index profile, enabling the creation of fibers tailored to specific applications.

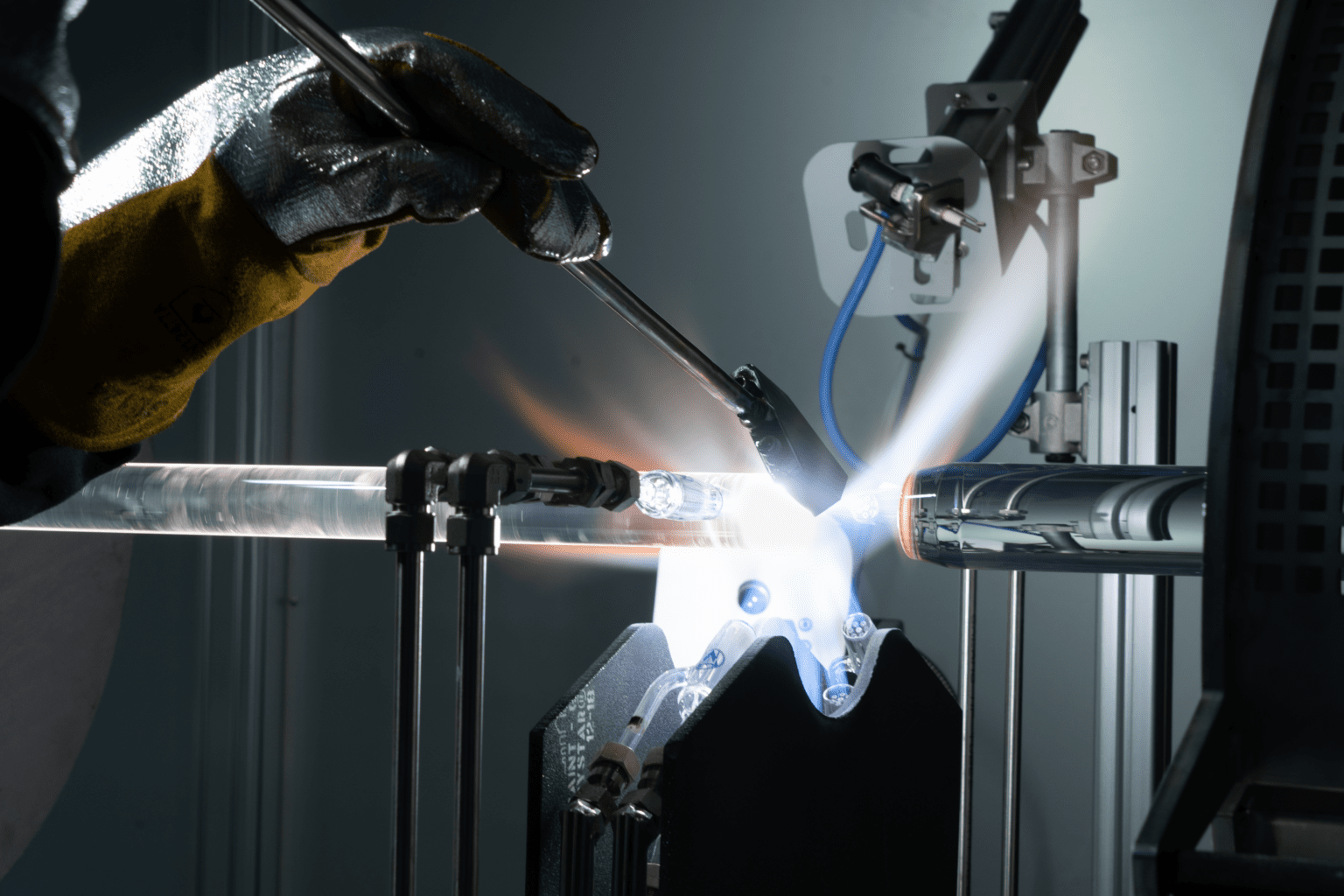

High Purity Deposits: Advanced plasma technique ensures that every layer is of the highest purity, ensuring optimal fiber performance.

Efficient and Scalable: Designed for both R&D and large-scale production, adapting seamlessly to your production requirements.

User-Friendly Interface: Equipped with an intuitive control panel and real-time monitoring, making it easy even for newcomers to the field.

Robust and Reliable: Built with longevity in mind, guarantees consistent results every time, ensuring an excellent return on investment.

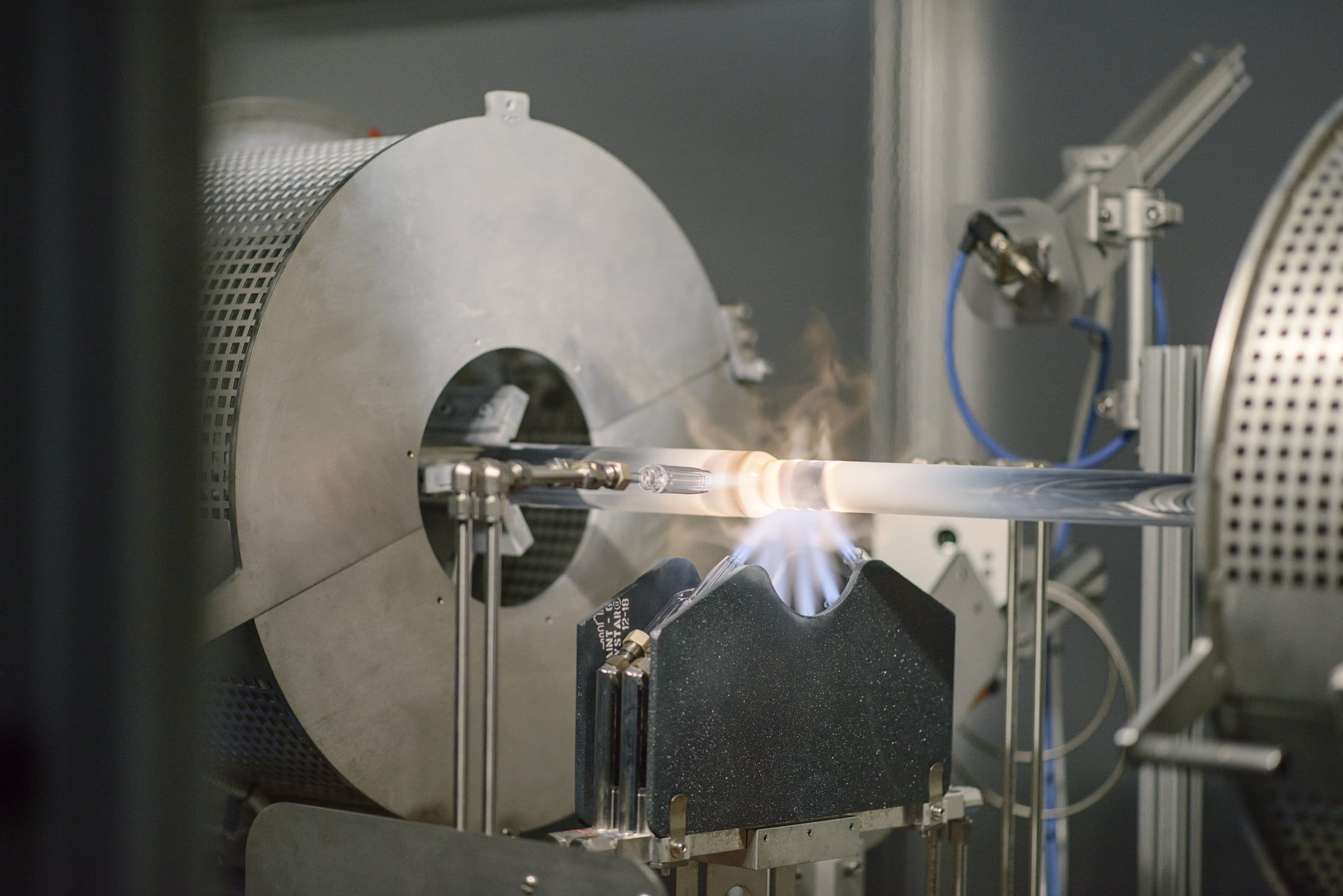

Glass-working, sleeving, and collapsing lathes:

Specifically designed to complement PCVD process in specialty preform production.

Lathes are supplied with all the instrumentation needed according to customer specific needs for high quality glass-working, sleeving or for collapsing purposes and are equipped with special burners for optimal results.

| product | description |

|---|---|

| horizontal glass-working and sleeving lathe system – OFC 15 | used for glass and preform processing in specialty fiber production. The lathe is suitable for various glass-working operations as well as for fire polishing and tube sleeving. |

| Collapsing Lathe | used for collapsing process. Once deposition phase is complete, the preform must be collapsed into a solid rod/preform before it can be drawn into specialty fiber. |

contact

get in

touch

with us