can you keep pace?

Rosendahl Nextrom machines are built for superior efficiency and speed.

enabling the best product possible

With our production equipment for the global cable&wire, optical fiber and battery industry, we focus on efficiency, quality and speed. With all 3 brands we deliver record breaking production equipment:

RD-A high-speed datacom insulation line

2,500 m/min

With this datacom core insulation line, you can produce a variety of cable designs—both solid and foamed— on a single line, at speeds of up to 2,500 m/min, with unmatched product quality.

MCM multicolor ringmarking system

80+ unique identifiable fibers

MCM redefines fiber coloring and ring marking. The integrated process enables over 80 unique identification combinations at speeds up to 1,600 m/min.

BMR 15 XTT enveloping and stacking machine

340 plates/min

The BMR 15X TT is the fastest and most efficient enveloping & stacking machine in the market. The new Twin Track (TT) concept adds value by saving your expensive floor space.

RD-A

Rosendahl core insulation line

for LAN and high-speed data cables

The RD-A core insulation line is equipped with the latest features for high-end data cable production.

Thanks to fully and semi-automatic processes, this extrusion line can be easily operated by a single operator.

Optimized for speeds up to 2,500 m/min, it features high-efficiency spray cooling, an integrated capstan with AC drive, low tension build-up, and a 3-step integrated drying unit.

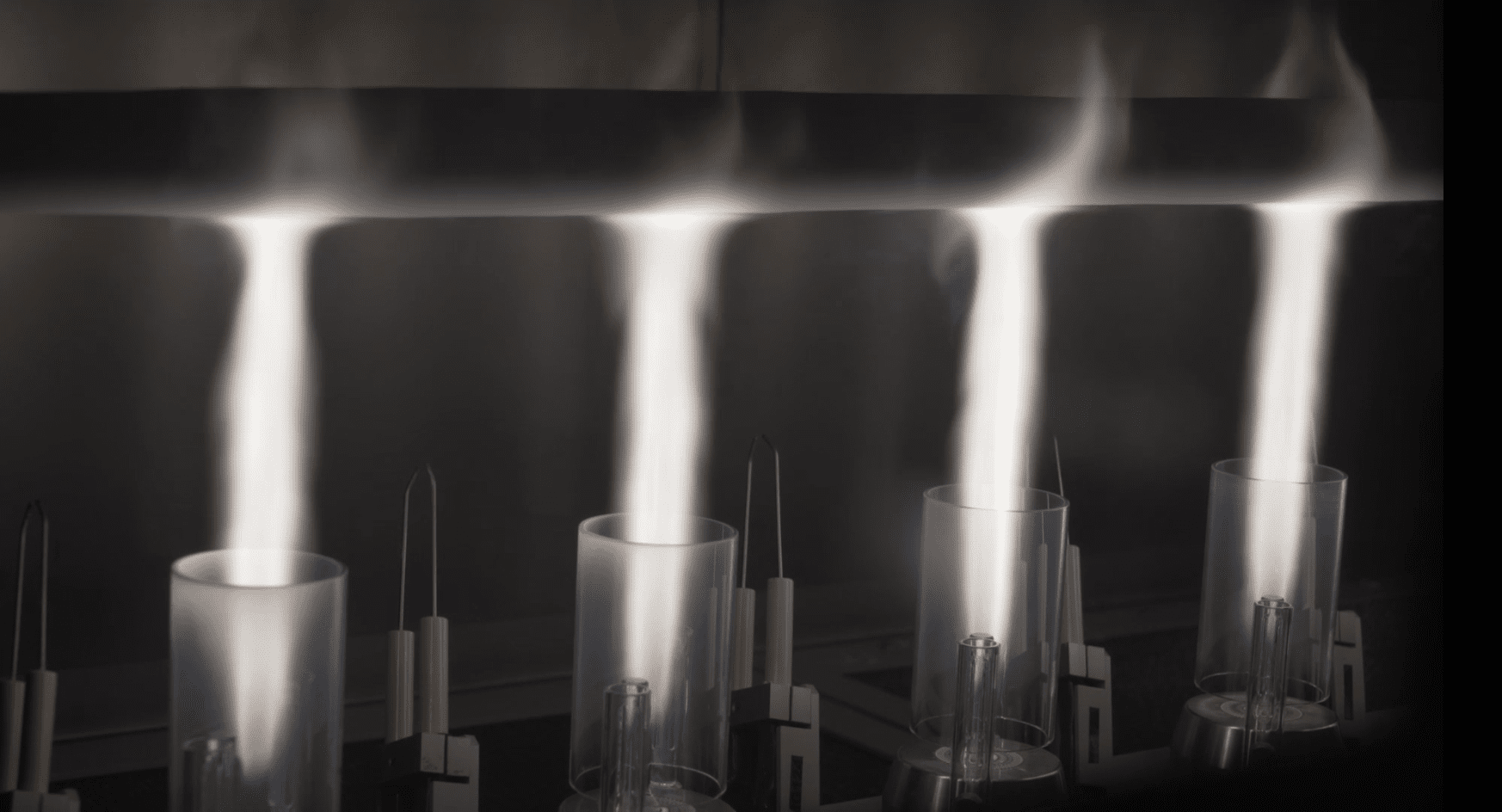

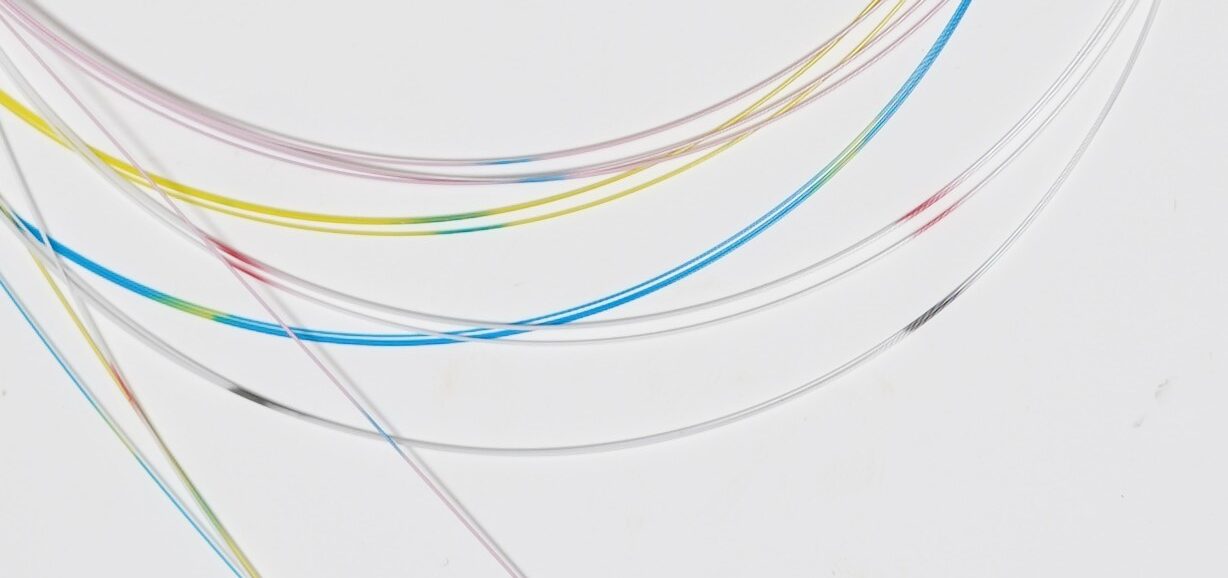

MCM Multicolor Ringmarking

Nextrom MCM High-Speed Multicolor Ring Marking System

MCM redefines fiber coloring and ring marking. Integrated directly within the fiber coloring process, it enables over 80 unique identification combinations, up from 36 in current standard solutions, at speeds up to 1,600 m/min. All with minimal attenuation and no need for extra dryers.

With MCM, you can simplify fiber identification, unlock new cable designs, and boost productivity. Achieving up to 50 % higher line speeds and 95 % lower attenuation increase compared to conventional inkjet systems.

Stable at 1,600 m/min, the system ensures consistent spacing, sharp rings, and seamless integration into existing Nextrom coloring lines.

BMR15 XTT

BM-Rosendahl enveloping & stacking machine for SLI and VRLA battery production

Although having enveloping 2 machines in one frame, you can handle them separately. For example, if you have to handle something at track 1, you can do so while track 2 is still running – this is no issue when having a BMR 15X TT.

The brand-new horizontal plate feeding unit and inclined plate feeders enable us to address double or missing plates immediately in the plate feeding unit. This functionality – combined with an improved machine concept using independent servo driven units – has enabled us to implement a unique automatic element repair system.

With our technical superhero called “X-factor” you can automatically detect and repair defect elements during running production.

do you know our LinkedIn channels? Follow our brands for more product related updates.

contact

do you want to know more?