high speed

for data

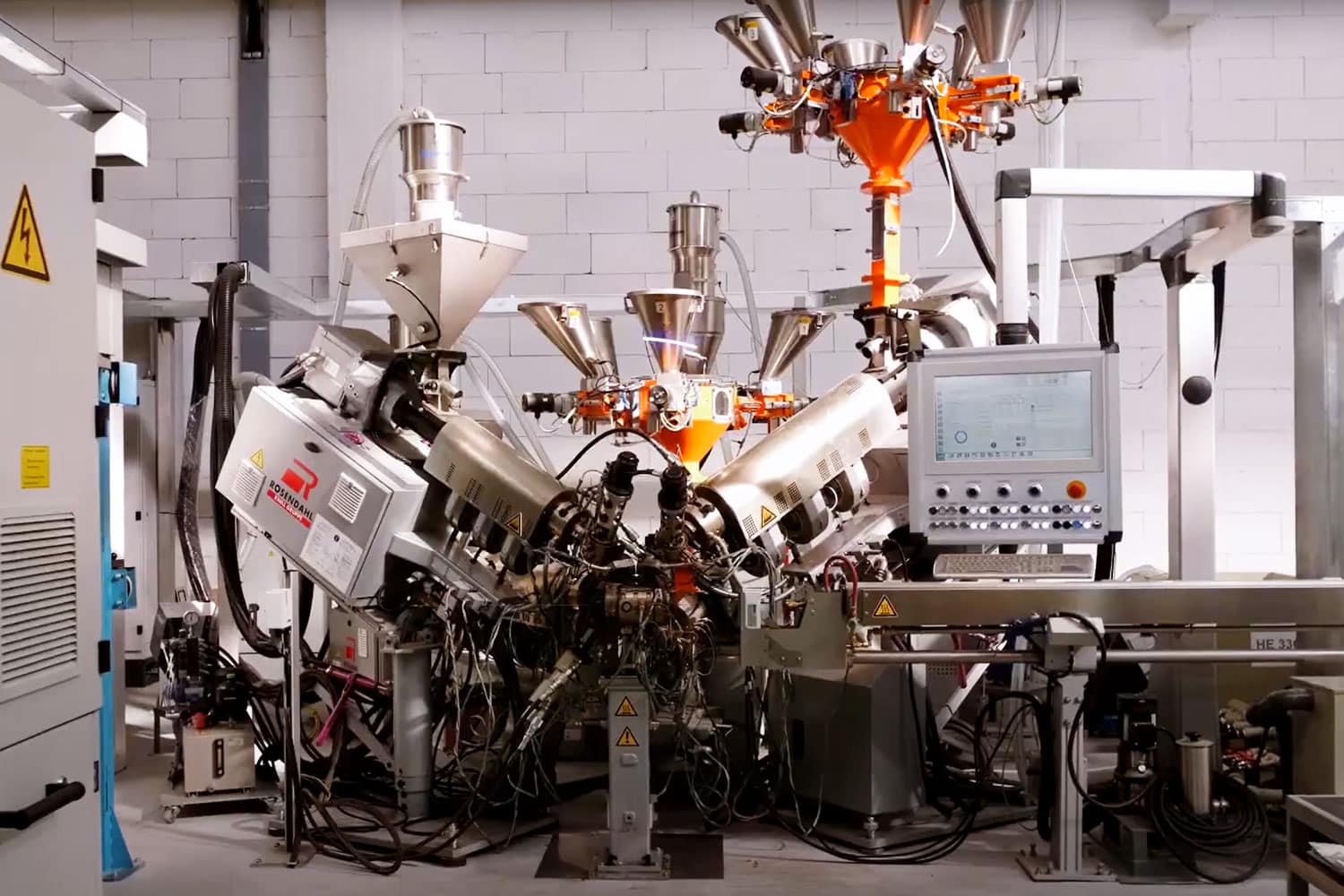

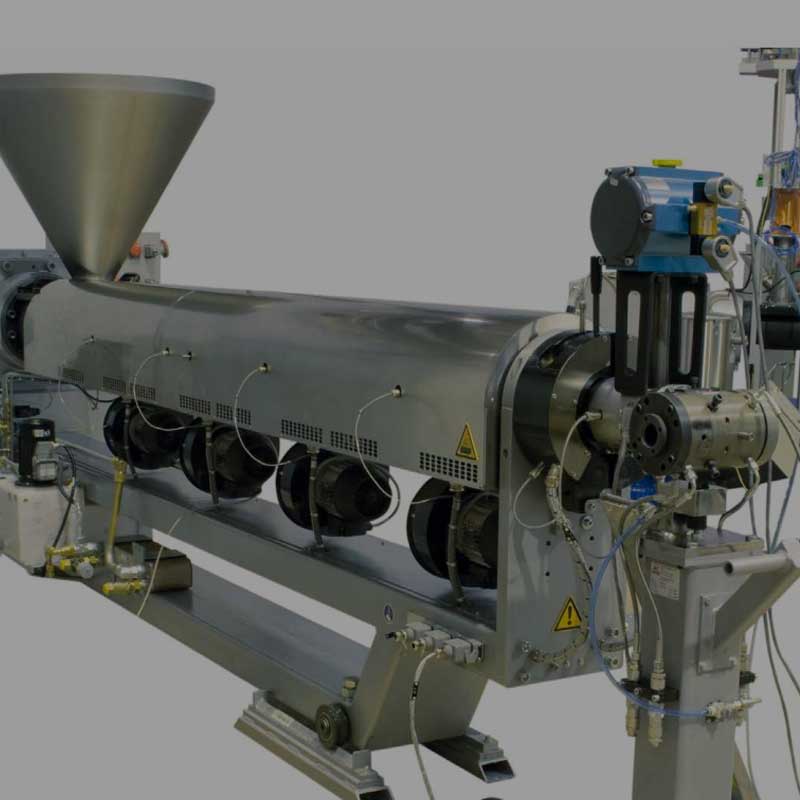

Insulation and jacketing lines by Rosendahl. Smoothly running machines for the production of any type of metal communication cables.

communication on the rise

The constant expansion of the worldwide telecommunications network is one of the essential factors for the rising demand of all kinds of data cables. Technologies in this field are developing rapidly. The increasing bandwidth requirements drive constantly improved cable performance. Fortunately, Rosendahl machines already offer the technology of tomorrow.

Highly flexible machinery

Manufacture a variety of cable designs, both solid and foamed products, on one line.

Switch between products fast and easily.

Stable production process

Run your production at a constant speed and tension.

For uniform cables with excellent product geometry and transfer rates, as well as minimum scrap.

communication on the rise

5G networks within reach

Transfer rates of 5G are not only necessary for surfing the internet or for phoning. In the communication between machines, like in the medicine field for example, the speed of data transfer plays a much more important role. The demand for the cables required for these applications is huge and growing steadily.

Smart homes and offices

Whether lighting, heating, or security cameras. To consume as little space as possible, cables must be highly sensitive and very small at the same time. Our Core Insulation Line was specially developed and has been constantly improved for producing special products like these.

Gerhard Hofer

your specialist for metal communication cable equipment

Rosendahl quality

High performance

for LAN cables

Rosendahl lines for LAN cable production are optimized for the highest productivity and easy handling. Well-designed processes make switching from one product to another as fast and easy as possible.

Our machines meet all production requirements for cable categories 5e, 6, 6a, 7, 7a, and 8.

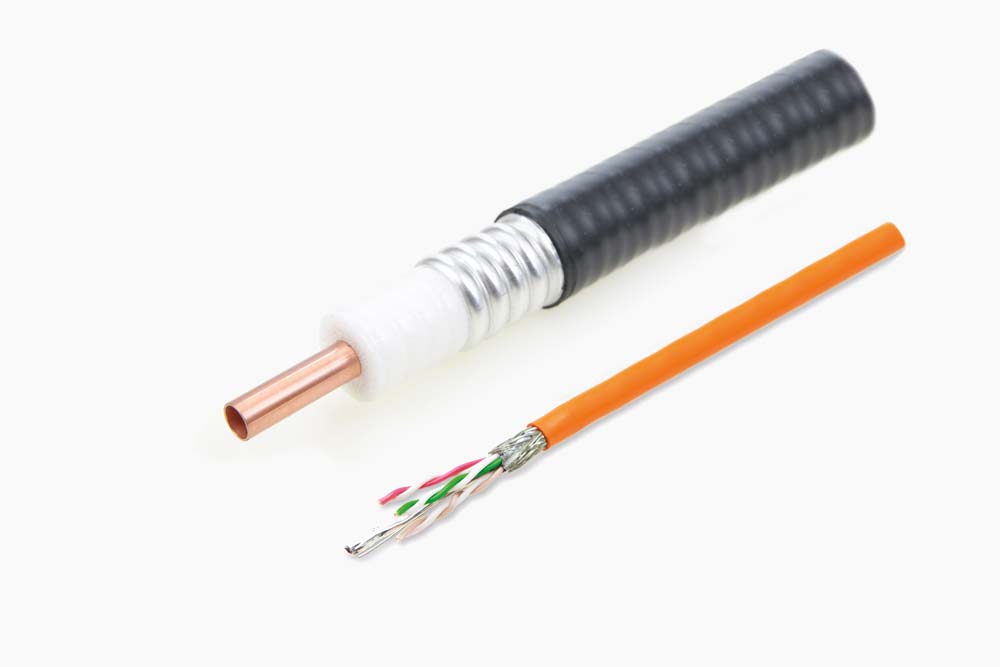

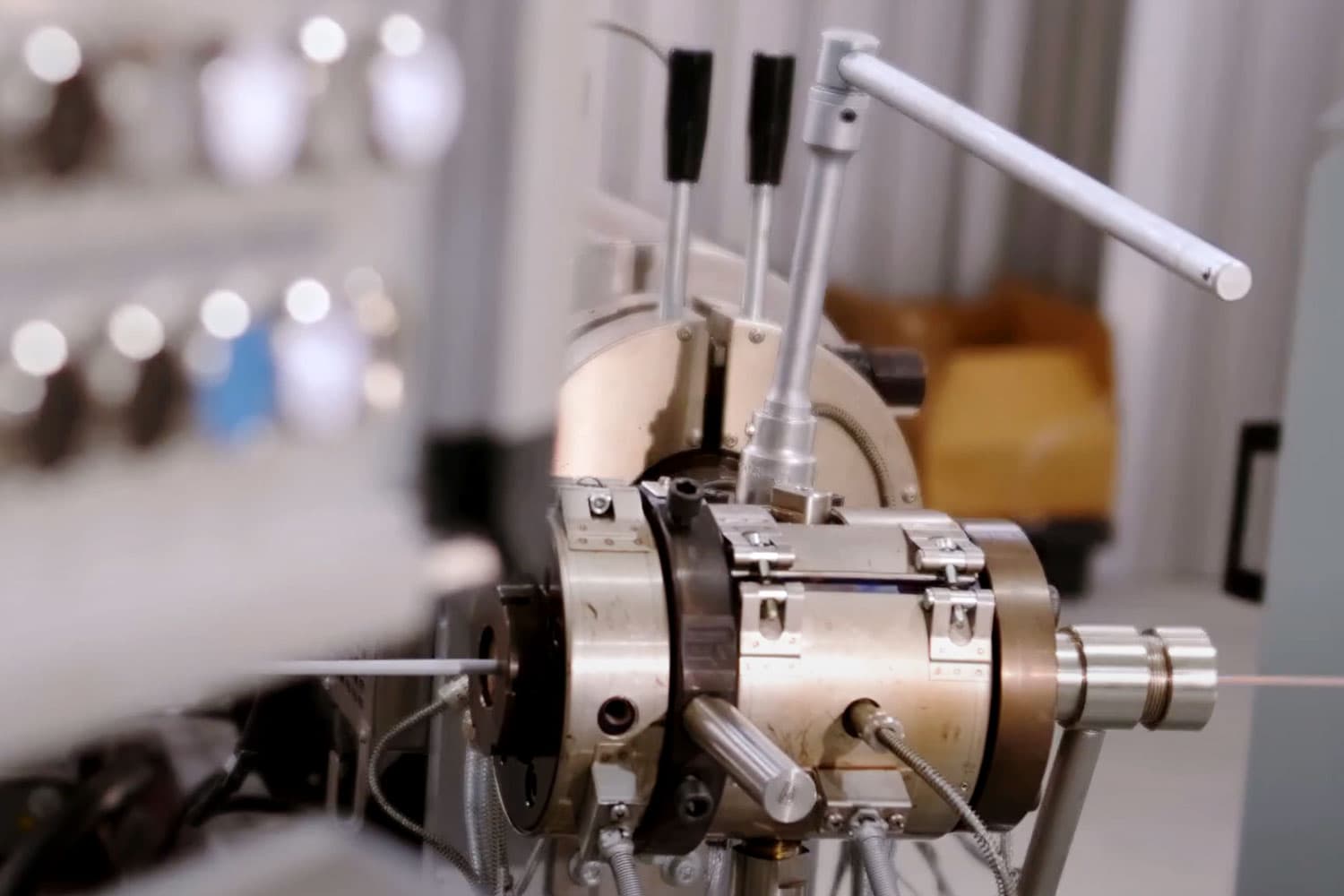

low-attenuation RF cables

Maximum power ratings.

Minimum weight

Low-attenuation RF cables are becoming a requirement in wireless communications. With reduced attenuation and enhanced parameters, cables’ maximum power ratings and signal propagation are increased, while weight is reduced. Our manufacturing systems for high-performance coaxial cables like these have been continuously developed to meet the requirements of today’s and future production processes.

Rosendahl process know-how for your success

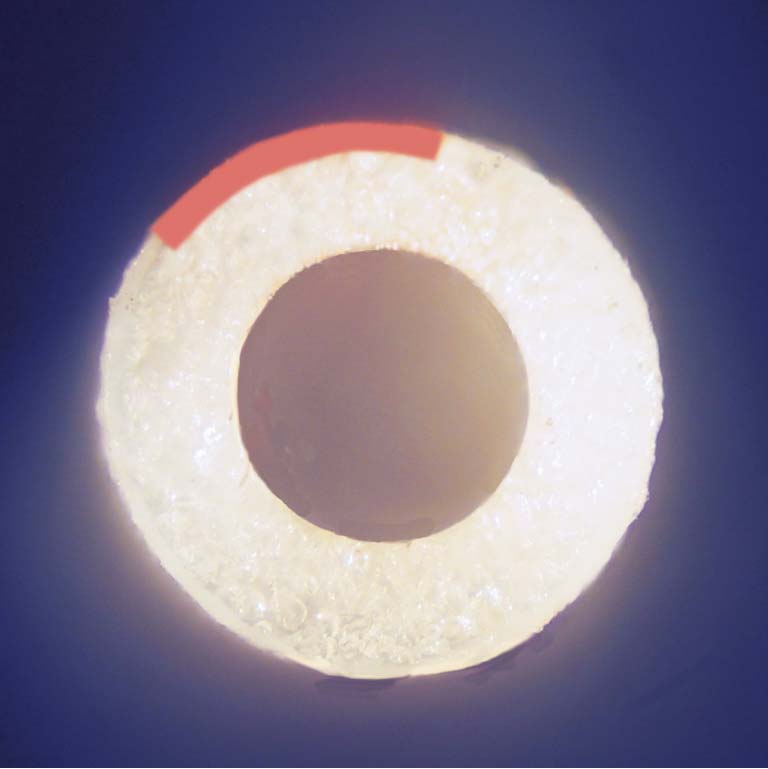

Get a fine and uniform foam structure – repeatedly

Foaming of high-end products with sensitive materials is one of our core competencies. The Rosendahl extrusion technology in combination with our high-pressure precision gas-dosing system ensures long-term process stability and a very fine and uniform foam structure.

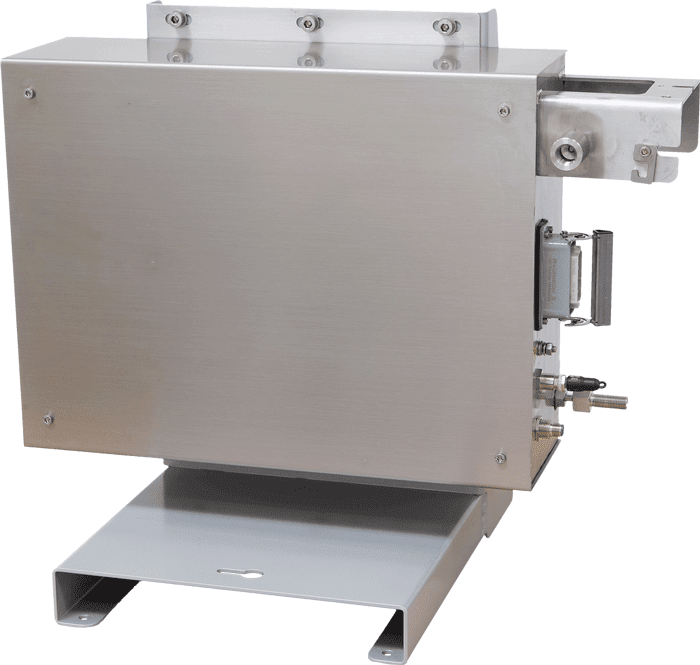

Rosendahl Mass Flow Control

Smart control of gas flow

for foam systems

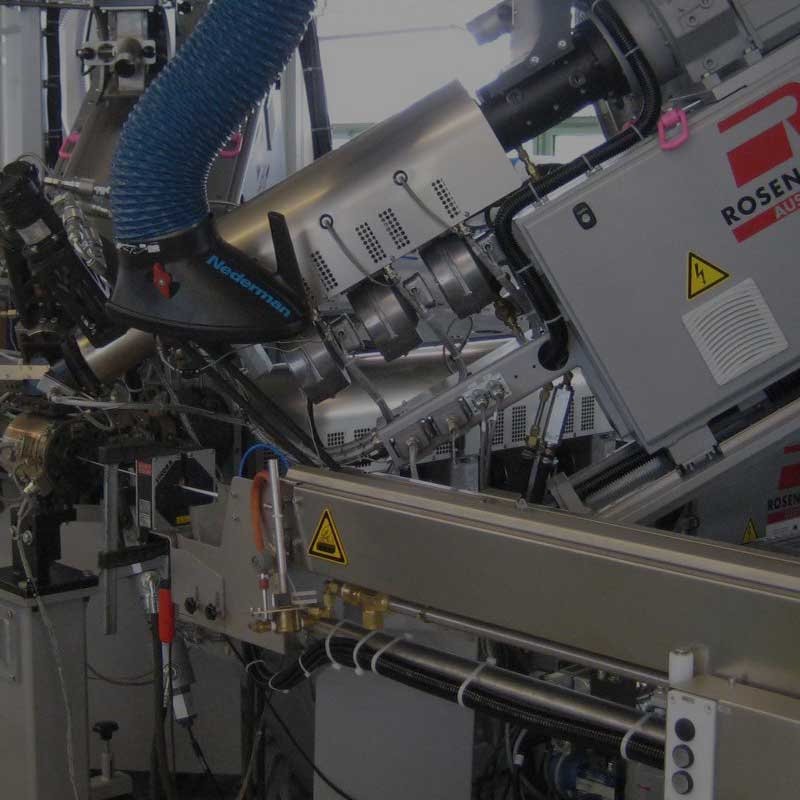

Imagine a system that controls the most critical part of the foaming process all by itself. Rosendahl Nextrom has developed exactly that. The Rosendahl Mass Flow Control unit (RMFC) is located between the high-pressure pump and the extruder. It automatically regulates the gas flow and constantly adjusts it throughout the whole production, which results in perfect repeatability by means of reaching a constant and evenly spread foam. For a perfect result from the very first second.

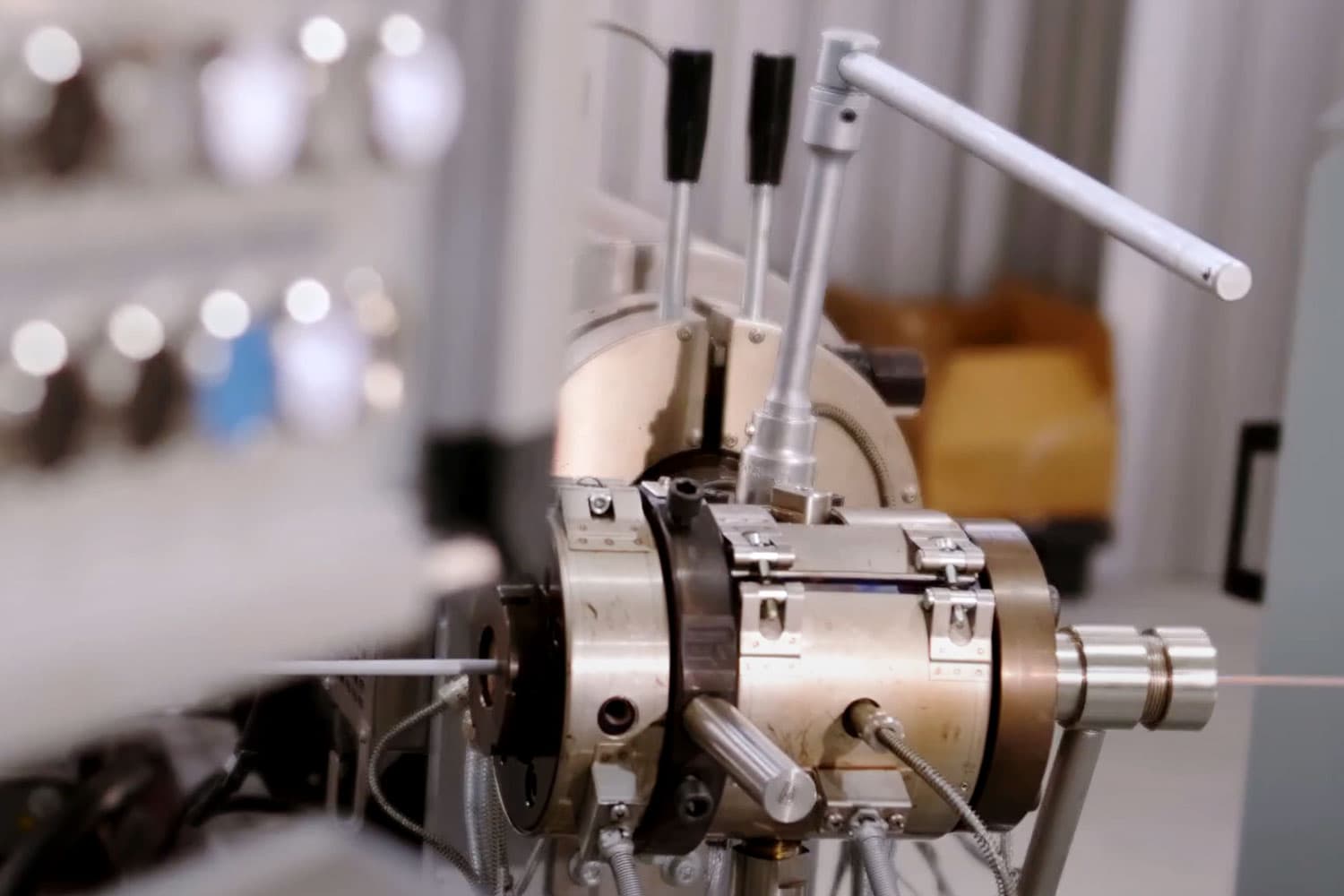

Rosendahl Gas Injector Valve

Steady datacom cable production - perfectly repeatable

Adjust your production process with minimal effort. Our new RGIV gas injector valve has been developed to produce foamed as well as solid cables without any adjustments to the gas injector. It is a self-sealing system and can be used for both polyolefins (PE/PP) and fluoropolymers (FEP/PFA).

This one-size-fits-all innovation is suitable for all required gas amounts and fits all extruder sizes.

- Scrap minimization thanks to 100% repeatability of gas quantity

- Constant gas flow and foaming process with improved regulation

- Plug-and-play solution plus easy handling

- No dismantling necessary (foamed/solid)

- Immune to environmental temperature fluctuations

overview

Rosendahl production lines for LAN and coaxial cables

RD-A

Core insulation line for LAN cables with annular and helical designs

RK-C

Core insulation line for radio frequency cable cores

RK-S

Insulation line for physically and chemically foamed mini-coaxial and CATV products

RK-W

Radio frequency corrugation line for annular and helical cable designs

RD-M / RK-M

Sheathing line for LAN and coaxial cables

efficient line control

Easy operation of complex processes

Gas plays a crucial role in the production of high-speed data cables. Too high or too low gas amounts can have consequences on the process stability and thus on the quality of the product. With the help of our powerful RIO line control and the newly developed gas systems, you gain full control over your production process.

- Establish the right conditions ahead of production

- Reduce start-up and changeover times

- Monitor, control, and analyze all relevant process parameters

contact

get in

touch

with us

You have specific questions about our production equipment? You want to know whether your desired product design can be realized on our machines? Don’t hesitate to contact us for further details on our machines and processes. Let’s find a suitable solution for your requirements.