the new WOW in optical fiber draw

June 05th, 2025

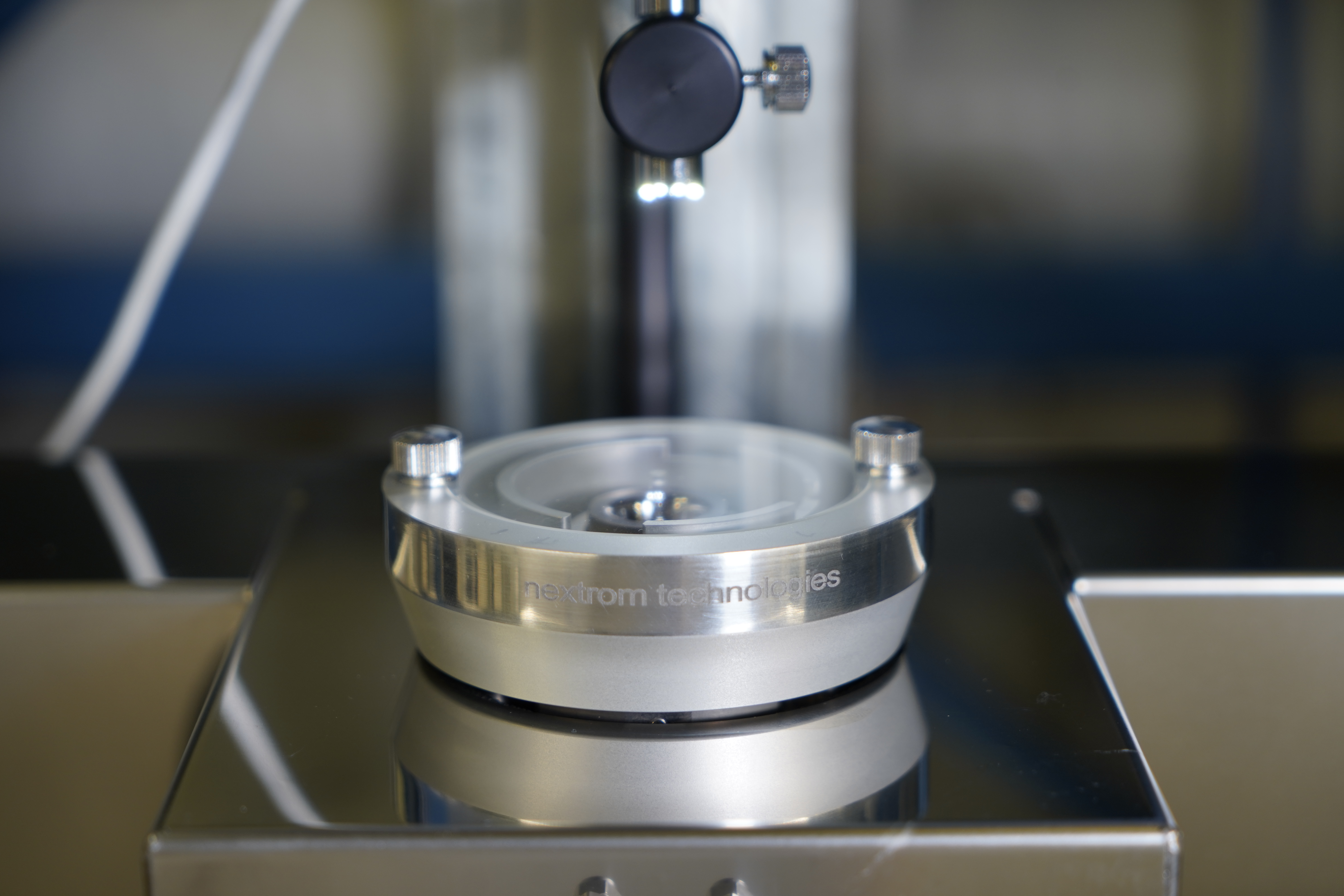

Ultra-high-speed Wet-on-wet Coating Applicator: Redefining precision for high-speed optical fiber manufacturing

contact person

Alain Giraud

alain.giraud@rosendahlnextrom.com

share

wet-on-wet coating applicator

Ultra-high-speed wet-on-wet Coating Applicator: Redefining precision for high-speed optical fiber manufacturing

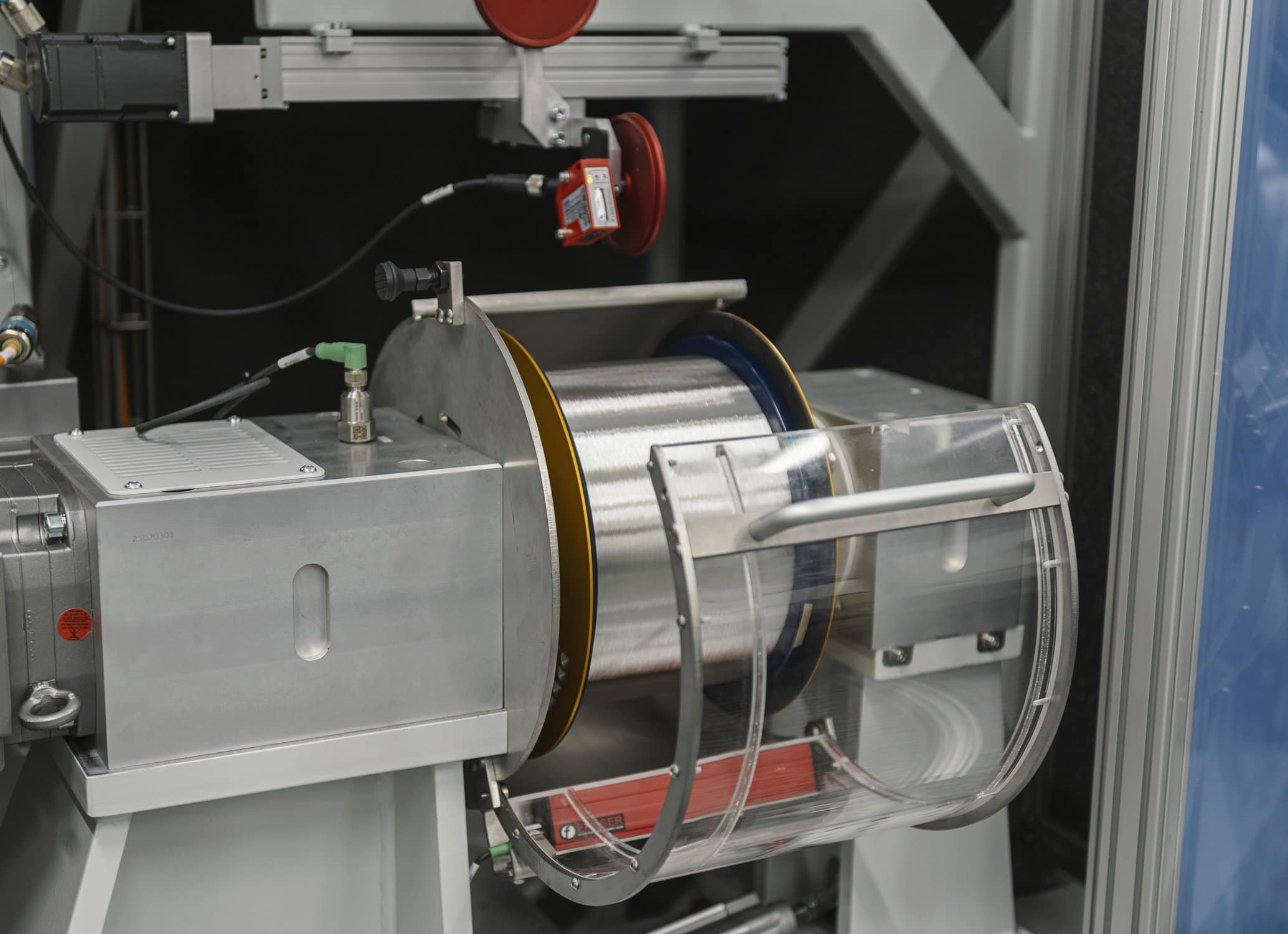

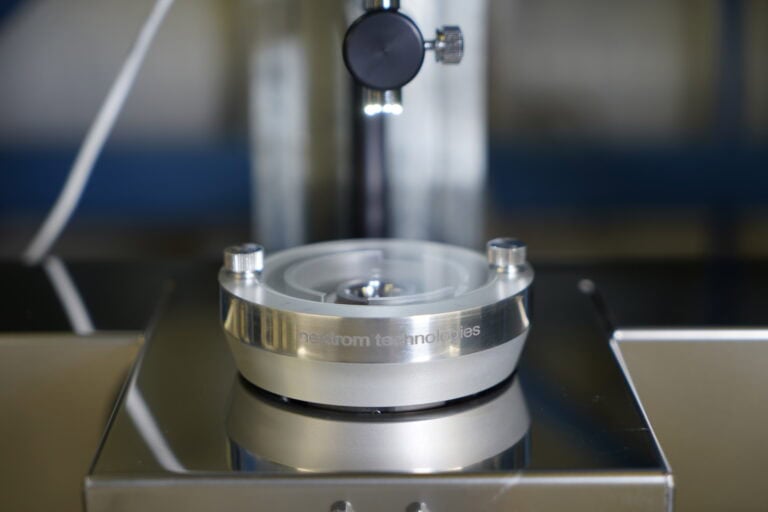

In a world where precision, speed, and quality are essential, the Nextrom Ultra-High-Speed Wet-on-Wet (WOW) Coating Applicator stands as a groundbreaking advancement. Engineered to deliver flawless coatings at extraordinary draw speeds, this innovative system sets a new benchmark in high quality optical fiber manufacturing. Whether you are optimizing internal processes or meeting customer demands, this coating applicator seamlessly combines advanced engineering, operational efficiency, and superior performance.

faster

precise

repeatable

outstanding in concentricity and circularity

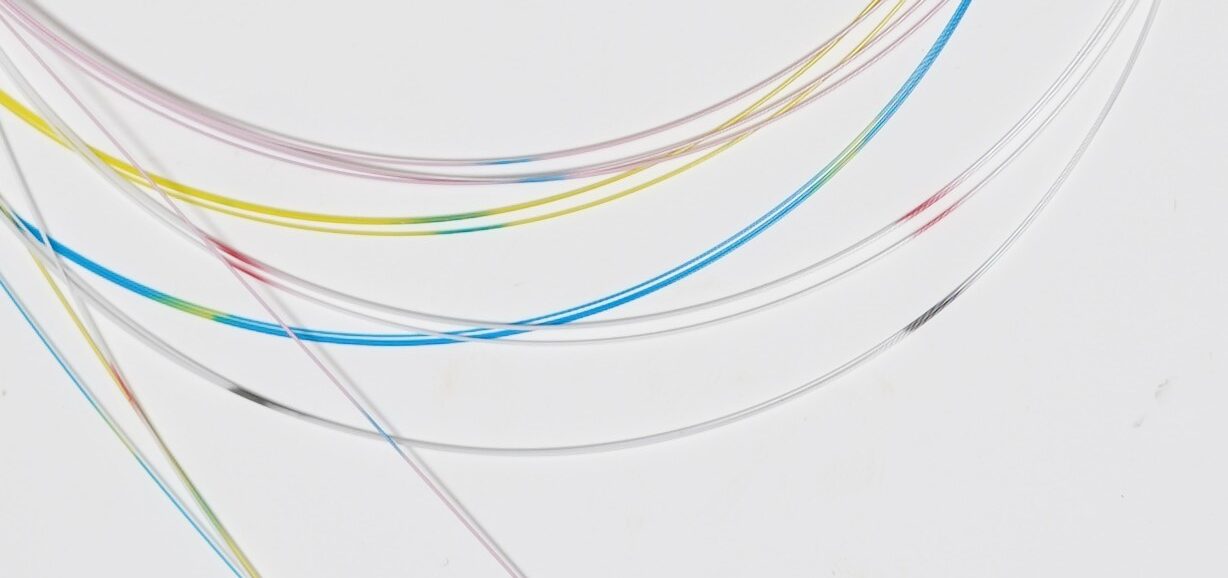

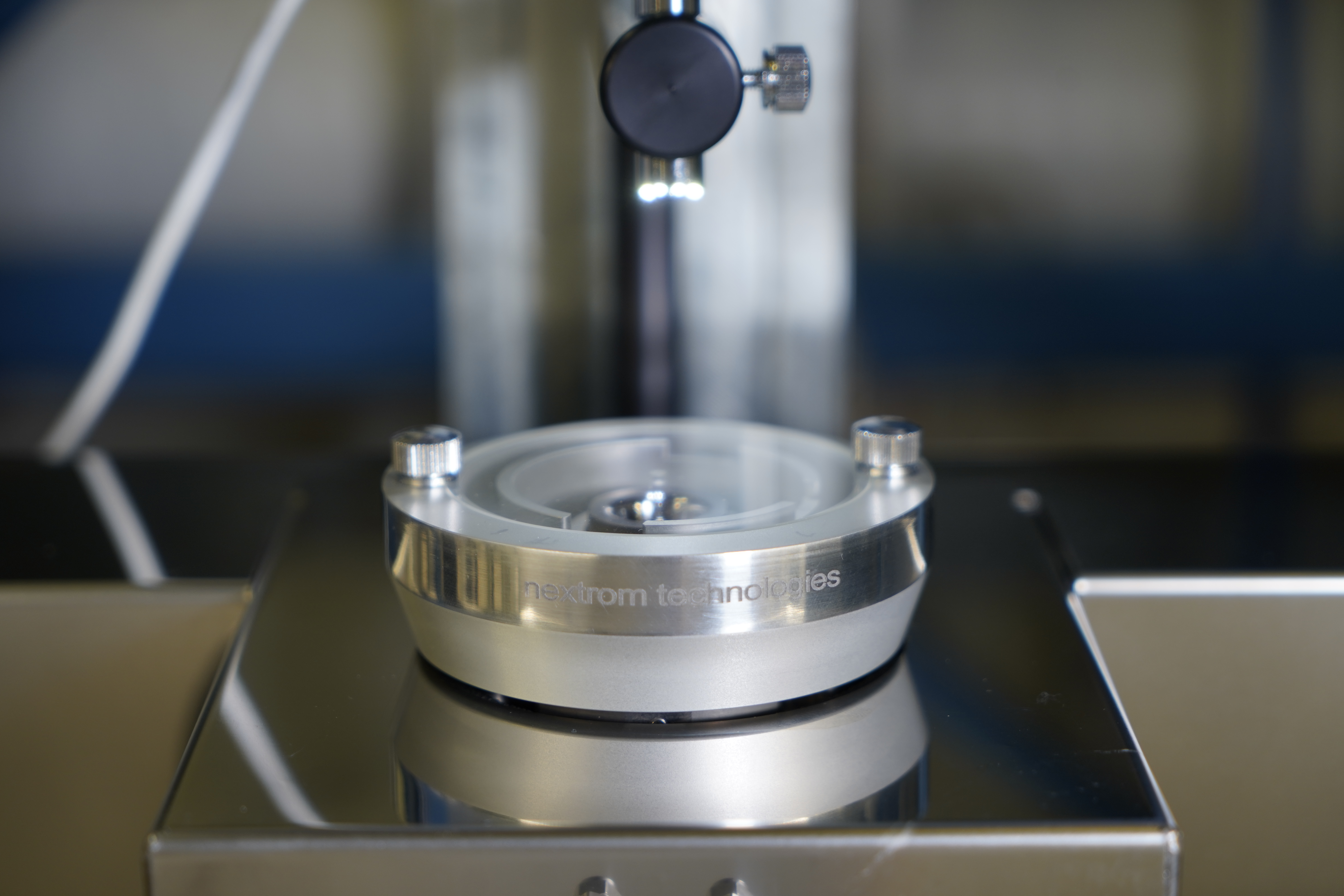

When precision is critical, the WOW- Coating Applicator ensures outstanding results. With coating-to-cladding concentricity of less than 6 microns – with mean of 4 microns or better – it guarantees exceptional alignment for best optical fiber performance.

Its advanced design minimizes coating non-circularity to below 5%, ensuring consistent mechanical and optical properties. Additionally, it delivers precise control over coating diameters, ensuring reliable and compliant products, free from common defects like bubbles, lumps, or delamination’s.

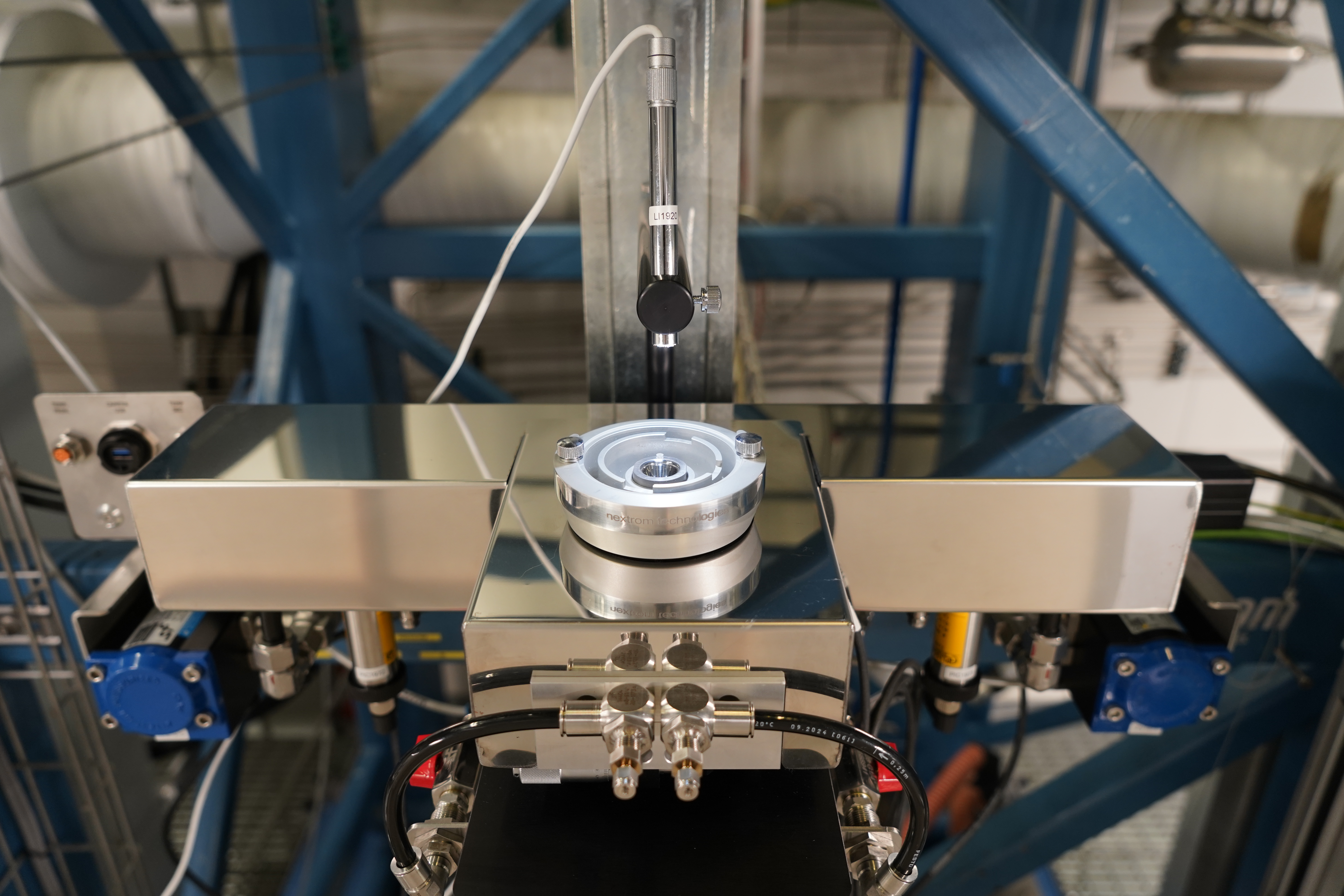

unmatched speed and efficiency

The applicator operates at ultra-high speeds of 3000–3500 m/min, delivering outstanding fiber production throughput while maintaining excellent coating uniformity and optical performance.

The system is currently finely tuned and calibrated for stable operation at a nominal draw speed of 3200 m/min, ensuring consistent quality and maximum efficiency.

Applicators wet thread-up functionality simplifies the threading process, reducing downtime and streamlining operations. By using a balanced meniscus principle, it ensures consistent fiber wetting and self-centering, minimizing alignment issues. A shorter bare fiber wetting length reduces fiber tension and torsional stress, enhancing both mechanical stability and product integrity.

Advanced conditioning for superior results

The Ultra-High-Speed Coating Applicator incorporates advanced conditioning systems for best performance. Water-circulated pre-tempering ensures stable material temperatures, while a closed-loop system continuously checks and adjusts pressure and temperature to deliver consistent, repeatable results with every application.

Built for durability and reliability

Designed for longevity, the applicator features strain-free XY table integration, which ends mechanical stress through balanced cable and hose routing. Constructed from robust, high-grade materials, it reliably withstands the demands of high-speed and high-pressure operations.

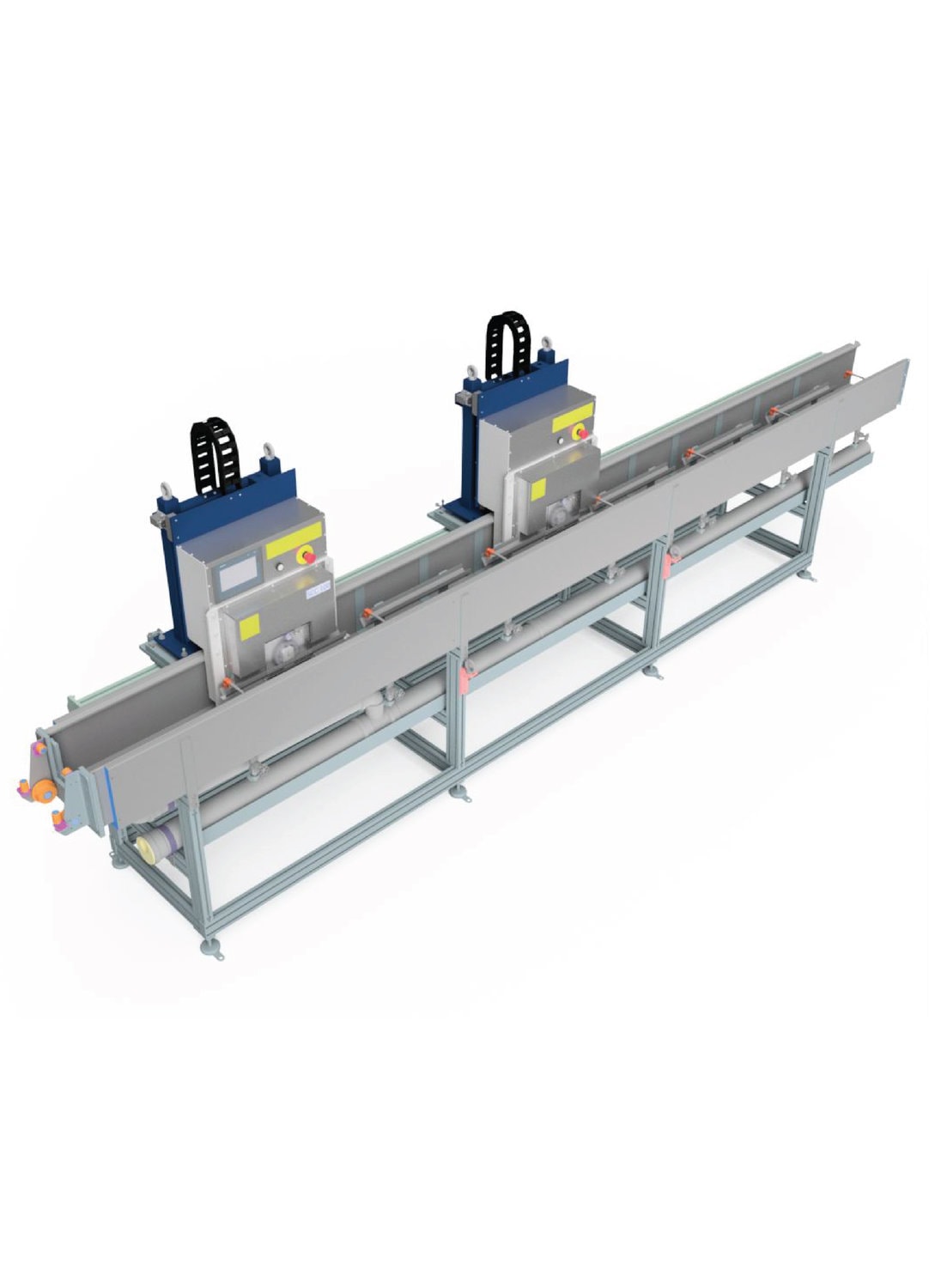

Seamless integration with Nextrom’s ecosystem

Fully compatible with Nextrom’s Advanced Continuous Acrylate Delivery System, the applicator streamlines material flow and ends common production disruptions.

Continuous automated filling capabilities remove the need for frequent tank swaps or manual filling operations, while precise temperature control ensures consistent material properties.

Integrated bubble removal and viscosity management support flawless coating application, even at maximum speeds.

Innovation for the future

The Ultra-High-Speed WOW-Coating Applicator is a transformative solution that empowers manufacturers to achieve unparalleled precision, speed, and quality. By streamlining operations and enhancing customer satisfaction, this system positions manufacturers for long-term success.

Transformative benefits for manufacturers and customers

This innovative system delivers significant advantages across multiple aspects of production.

- Achieve higher productivity with increased production speeds and reduced downtime,

- Minimize waste and operator workload with advanced conditioning systems and intuitive operation.

- Enhance product quality and reliability with superior precision and defect-free coatings, leading to higher customer satisfaction.

- Lower production costs and improved ROI thanks to fewer defects and more efficient resource use.

contact

get in

touch

with us