IWCS Cable & Connectivity Industry Forum

when?

Oct 15th – Oct 16th, 2024

where?

Providence, Rhode Island

contact person

Harri Turunen

+1 828 464 2543 304

harri.turunen@rosendahlnextrom.com

share

IWCS 2024 in Providence

meet us at booth 301

- AI datacenters are booming worldwide.

- The electric vehicles of the future demand new kinds of cables.

- And the power grid must keep up with all these developments.

We support these mega trends with new and improved solutions for the cable and wire market.

Increasing production capacity in datacom and telecom

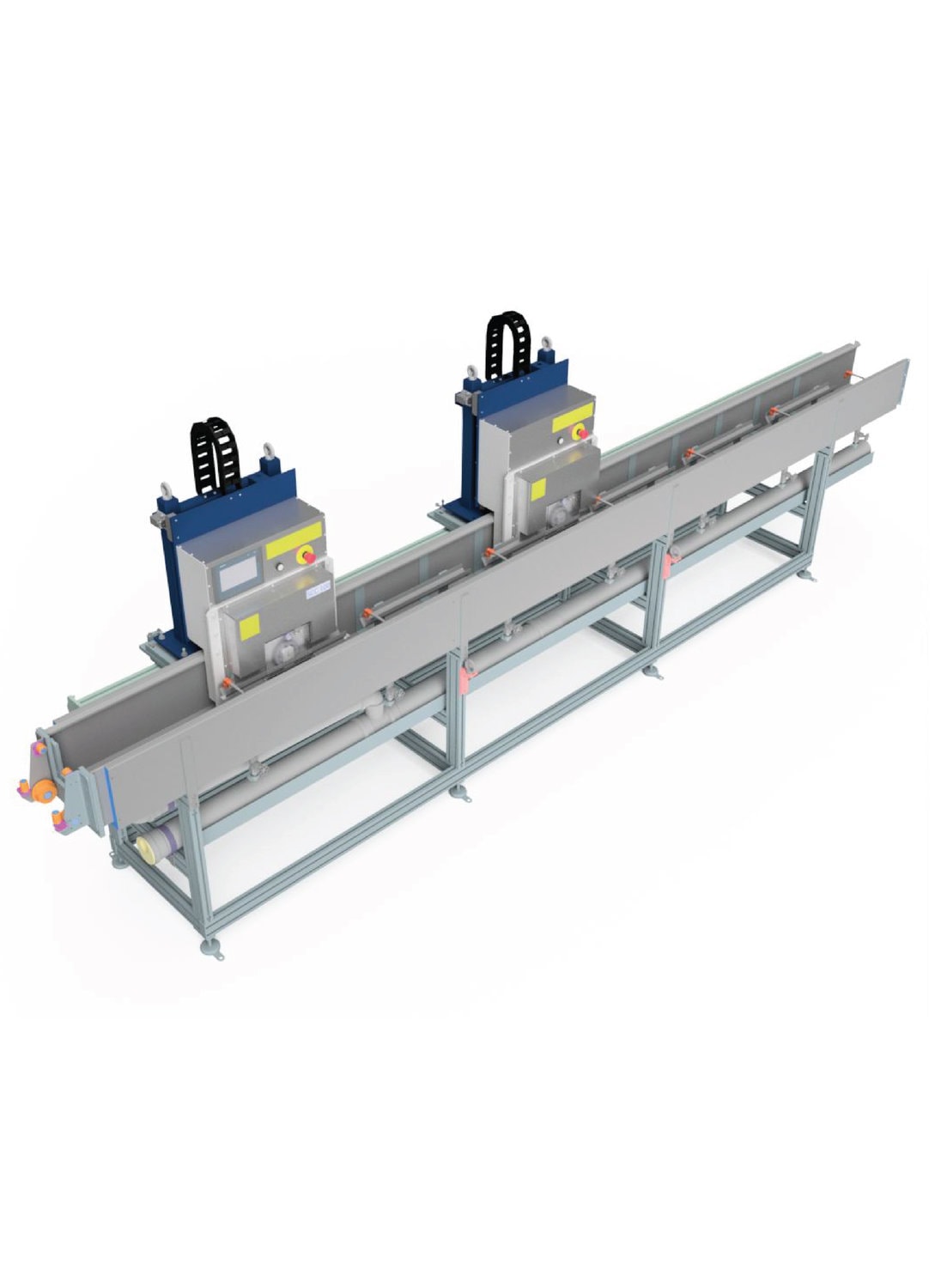

The demand for high-speed data infrastructures continues, as does Rosendahl Nextrom’s R&D work in this area. The company offers production lines for fiber optic and copper cables, optimized for high-speed production and equipped with many standout features for scrap reduction, quality control, and automation.

Rosendahl’s high-temperature physical foaming lines can manufacture cables with unique properties. For the use in high-end applications, such as medical or aerospace technology, or AI data centers.

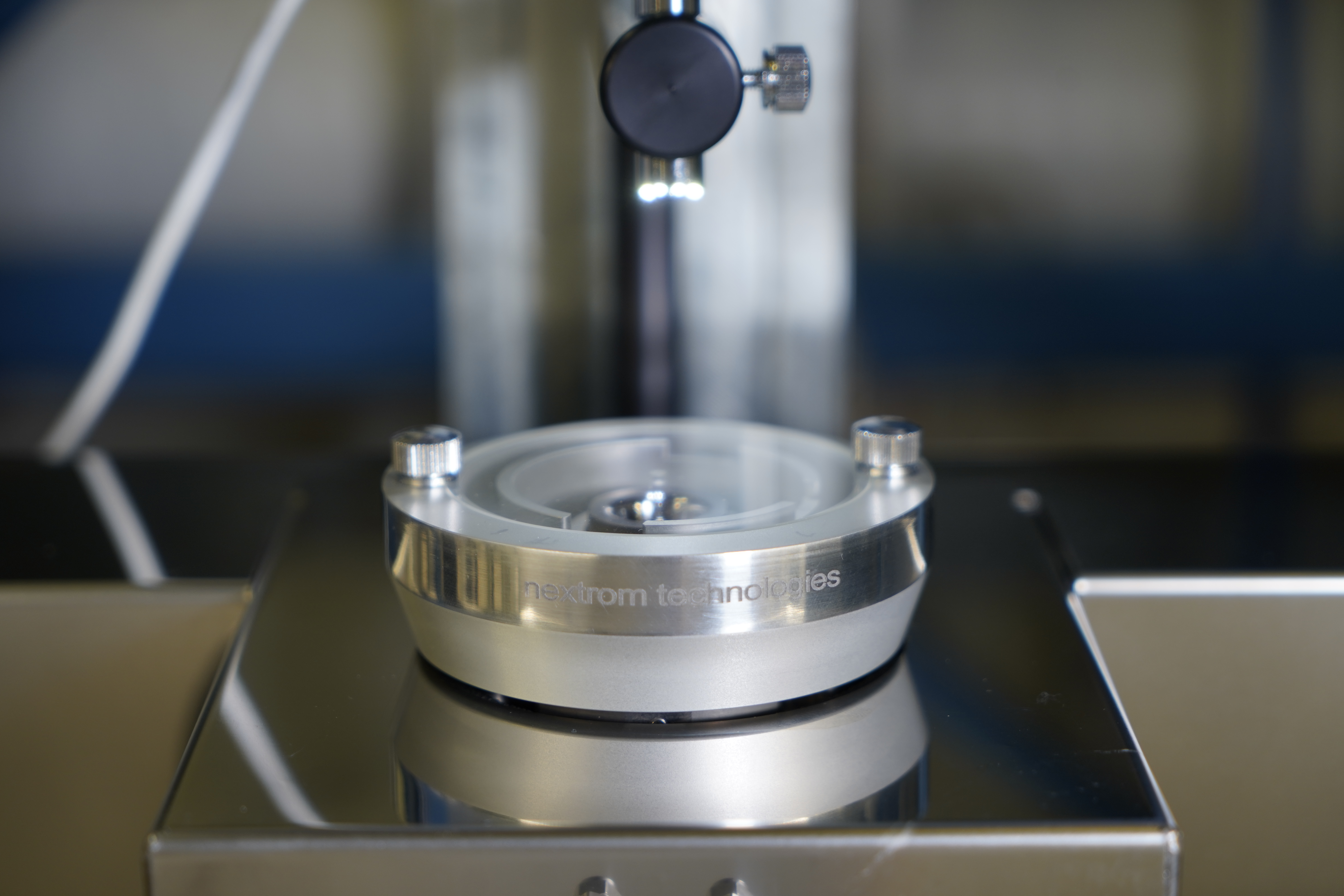

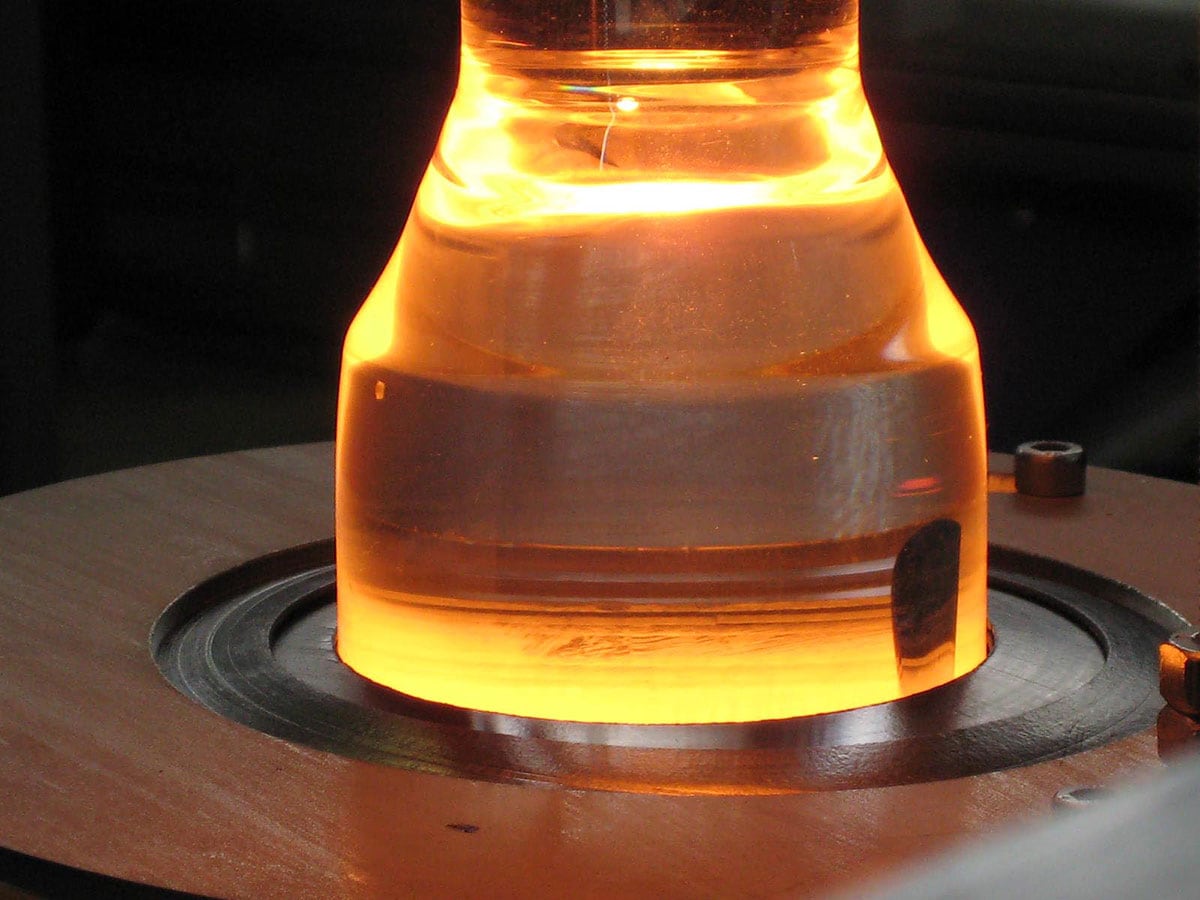

Nextrom is revolutionizing preform manufacturing with a combination of Vapor Axial Deposition and Outside Vapor Deposition technologies tailored for producing large-sized preforms with the lowest operational expenses. Furthermore, the telecom fiber drawing process has been optimized to reach impressive speeds of up to 3,500 m/min.

Accelerating e-mobility and energy transition

With batteries as the new energy source in modern cars, vehicle wiring is changing. New types of cables and wires are needed for both propulsion and power distribution. Recently, Rosendahl introduced the world’s first turnkey extrusion line for hairpin insulation. It makes a safe and reliable power supply at 800+ possible and minimizes energy losses in electric board systems. Other solutions for the automotive industry include busbar insulation, high-end charging cables and high-performance data cables.

Rosendahl Nextrom’s sustainable concept for forming, welding, and jacketing flexible materials and product sizes on a single production line is well-suited for connecting wind farms, photovoltaic farms, and offshore projects to the power grid.

Innovating smart and responsibly

Along with high performance comes high responsibility. A major focus of Rosendahl Nextrom’s efforts is the thoughtful use of materials, waste reduction, minimizing wear, and enhancing energy efficiency.

Their powerful line control offers a wide variety of possibilities to continuously improve production. ESG-compliant measurement of CO2 and energy consumption has been added to Rosendahl Nextrom’s smart portfolio, ready to support the green transition in the industry. An AI-based process control further improves process stability and product quality for datacom cables. Another user-friendly yet powerful solution has been designed to simplify the complex task of maintenance management. Customers who integrate it into their workflow can expect increased equipment reliability, reduced downtime, and improved operational efficiency.

In the field of telecom fiber drawing, Nextrom is leading the way towards more sustainable production: A Helium Recovery System recovers up to 90% of the used helium, effectively reducing dependence on this limited resource. The return on investment for this system can be achieved within a year, considering the current prices and availability constraints of helium. Addition, the Nextrom Induction Furnace drastically cuts down on energy consumption.

Skip the line and contact us in advance for an individual appointment. This way you can better plan your stay at the forum.

contact

get in

touch

with us