flexibility

for large dimensions

Extremely versatile metal tape-forming and welding technology for high- and extra-high voltage cable production

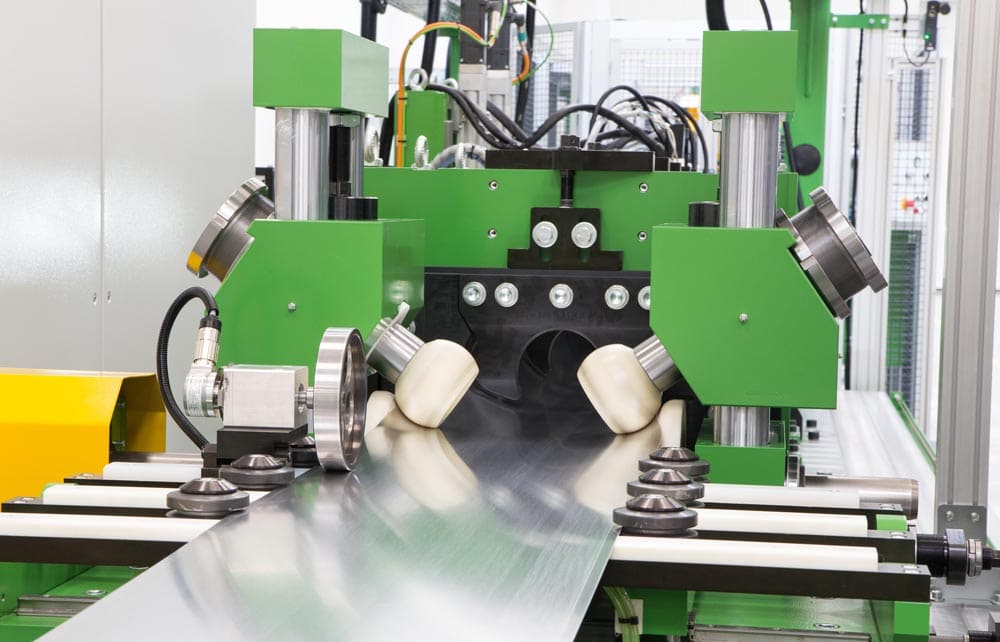

RH-W metal tape-forming and welding line

The Rosendahl RH-W metal tape-forming and welding line with tandem extrusion is an all-in-one solution with many benefits for the final product.

High- and extra-high-voltage power cables can be designed in many different ways – depending on their field of application. They need strong protection against all kinds of stress with electrical conductivity given at any time. That’s why we developed the RH-W, a production line for manufacturing high- and extra-high-voltage power cables of outstanding quality.

Production machinery for

off-line manufacturing

For a stop-and-go process, utilizing less floor space

Production machinery for

in-line manufacturing

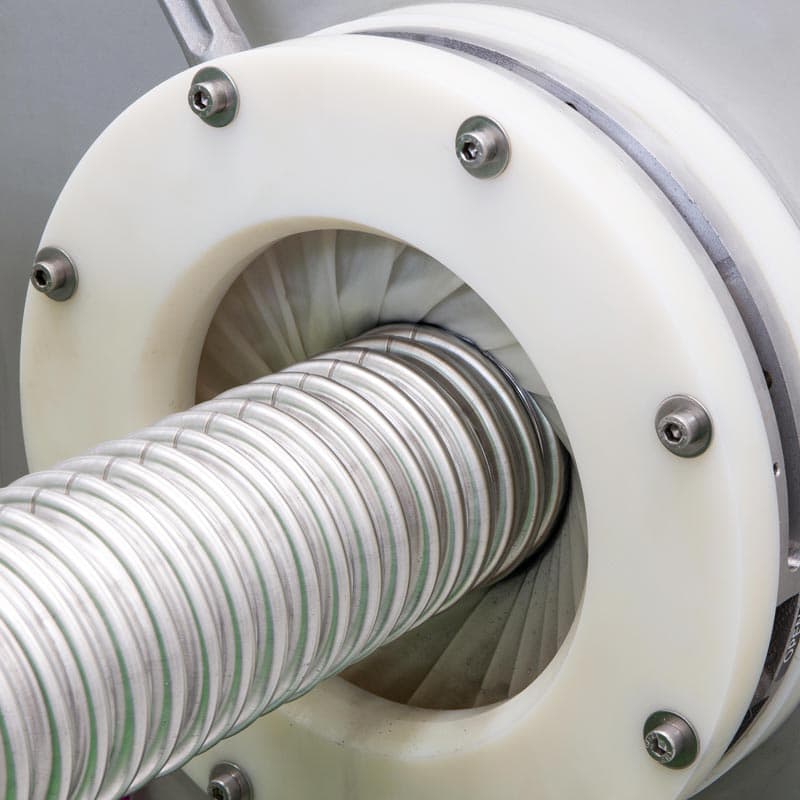

with subsequent jacketing in a tandem process

Forming, welding, and extrusion. These key processes and the associated components are developed by Rosendahl. That brings you considerable advantages, from consulting and line configuration to service and spare parts procurement.

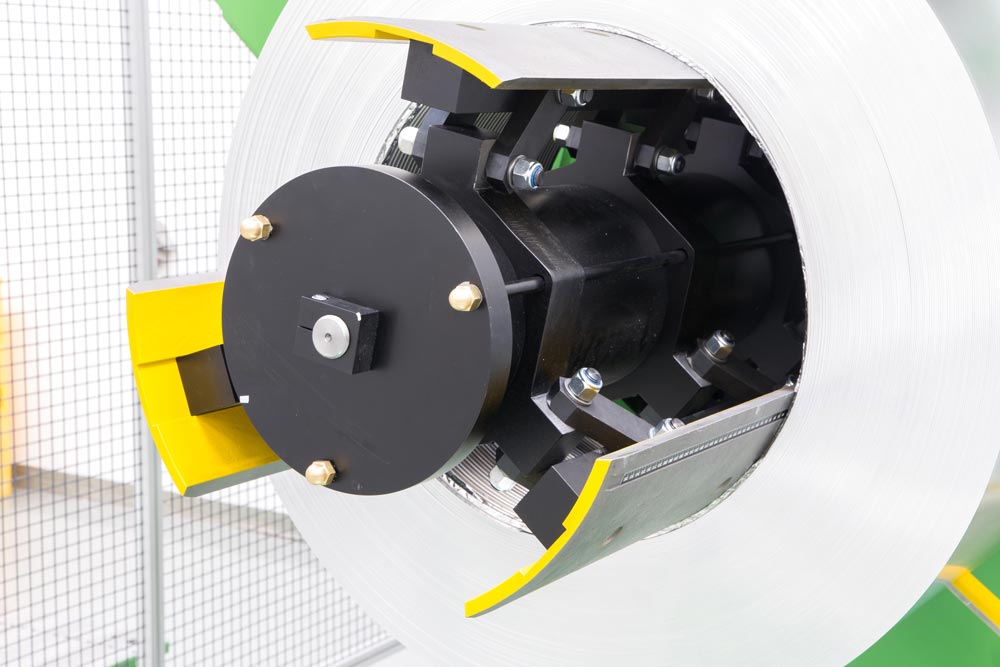

Metal shielding for a wide product range

The extremely versatile metal-shielding technology provided by Rosendahl covers a very wide range of product designs. Basically, almost any cable that needs metal shielding can be produced on the original Rosendahl RH-W metal tape-forming and welding line.

- chemical plants, refineries, mines, and factory environments

- designs for dry locations, indoor, outdoor, direct buried, conduit installation, ducts

- underground cables

- dynamic cable for floating platforms with corrugated copper sheath

- export cables for offshore wind farms

- cables for photovoltaic power plants

flexibility for your production process

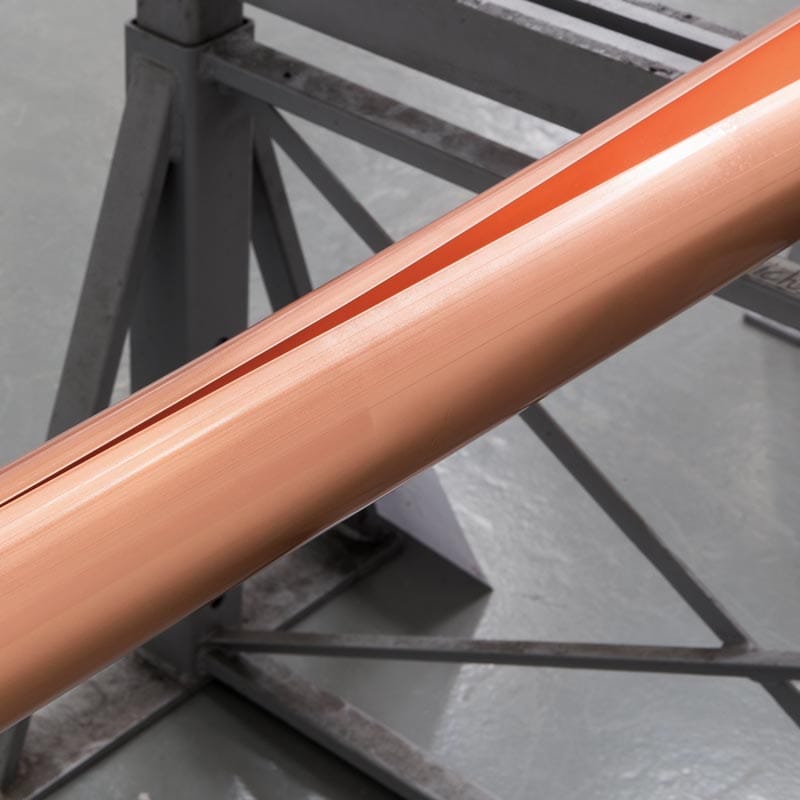

Don’t limit yourself to one material anymore

With our powerful RH-W metal tape-forming and welding line, you can process copper, aluminum, stainless steel, and alloys on the very same production line. No need to limit yourself to one metal anymore. That opens up many possibilities for high- and extra-high-voltage cable manufacturing.

100% data traceability throughout the whole process

Quick-change mechanism for different product dimensions

Easy, safe, and repeatable handling for line operators

for a more sustainable future

The technology to replace lead

in subsea cables

Since 2020, lead has been listed as a Substance of Very High Concern (SVHCs) by the EU and will be substituted in the near future. Rosendahl’s RH-W production line provides the technology to help producers to make cables more sustainable without lead. Copper, for example, is used as an alternative material. Properly processed, it forms a strong metal shield with outstanding mechanical protection and an equally strong water barrier.

Thomas Kulmer

your specialist for high- and extra-high-voltage cable manufacturing

flexible and high-performance solution

Endless production runs with superior welding technology

Rosendahl’s multi-torch system allows for high-speed and continuous welding. The welding electrodes alternate. While one is welding, the other can be exchanged or maintained. Continuous production is crucial for an efficient production flow and this enhancement has elevated the manufacturing process to a new productivity level. The line does not have to be stopped and production continues without waiting.

- Freely configurable high-end welding sources

- All welding parameters 100% PC controlled

- Welding technology synchronized with the production process

- Automatic electrode-positioning system

technical data

RH-W metal-tape forming and welding line

-

Tube diameter 50 - 200 mm

-

Tape material aluminum, copper, stainless steel, alloys

-

Tape width 100 - 650 mm

-

Tape thickness 0.5 - 3.5 mm

-

Tube design smooth, corrugated

-

Welding method TIG, laser

-

Production speed up to 15 m/min

Tailor-made in Europe

according to your individual requirements

contact

get in

touch

with us

If you produce power cables and wish to get the key processes of forming, welding, and extrusion from one source, get in touch! No matter what your quality requirements are, we will be happy to develop a solution that fits your requirements.