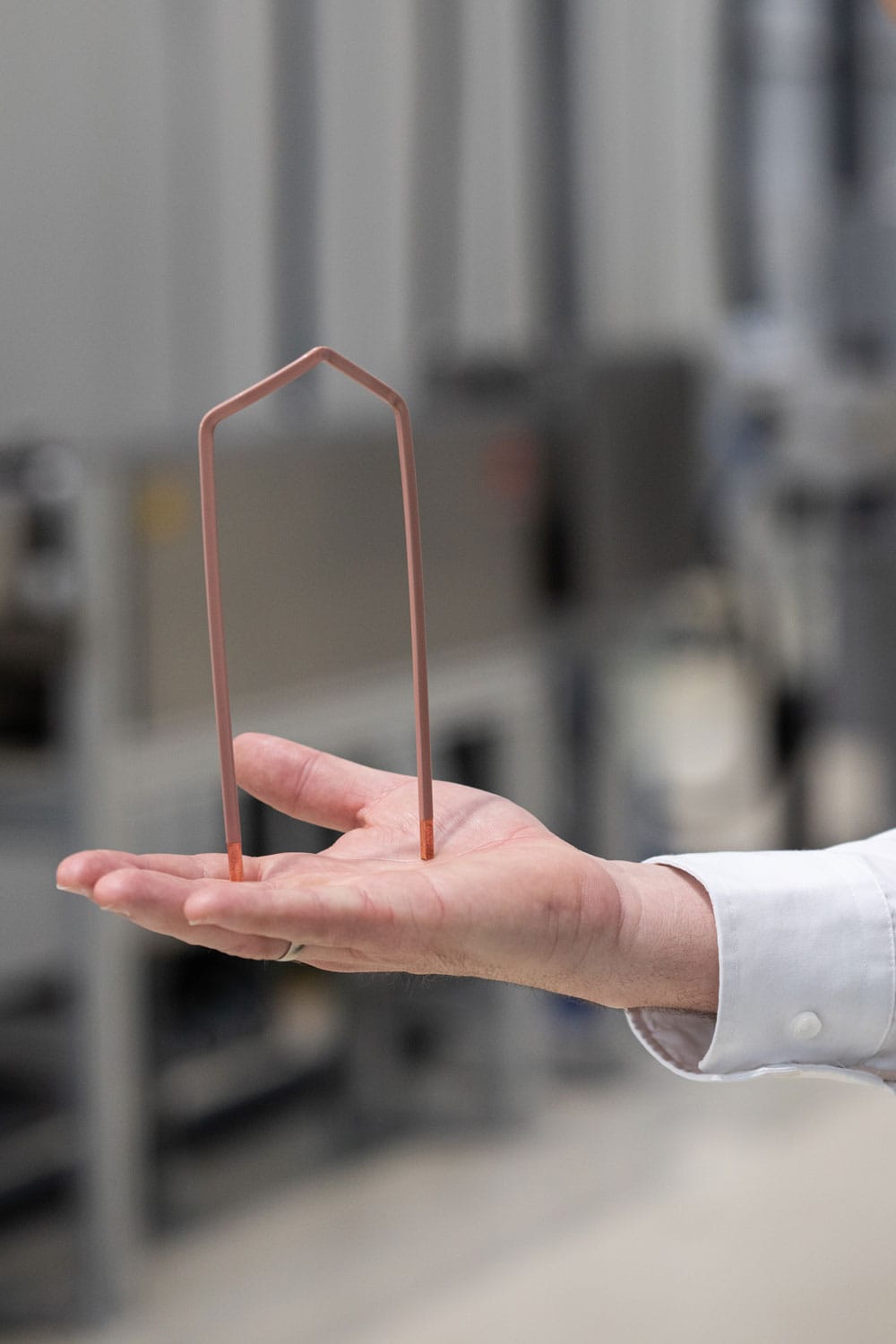

hairpin extrusion from A to Z

Get to know the first industry-ready hairpin insulation line for the safe and efficient use of hairpins at 800V and above

1st turnkey hairpin extrusion line

RA-I, the first industry-ready turnkey hairpin extrusion line worldwide, is your all-in-one insulation solution for the safe and efficient use of hairpins at 800V and above.

Compared to conventional enamelling solutions, the extrusion process is significantly faster and more energy-efficient.

From pay-off to take-up, every line component of the RA-I extrusion line has been carefully synchronized to meet the high demands of the rectangular hairpin wire.

stable breakdown voltage

Extruded wires achieve stable breakdown voltage after thermal shock with just one layer of high-performance plastic.

firm adhesion

To attain their distinctive shape, hairpins need to be bent and twisted multiple times. The adhesion of the extruded insulation layer withstands these forces perfectly.

high temperature stability

chemical stability

superior electrical properties

mechanical stability

abrasion resistance

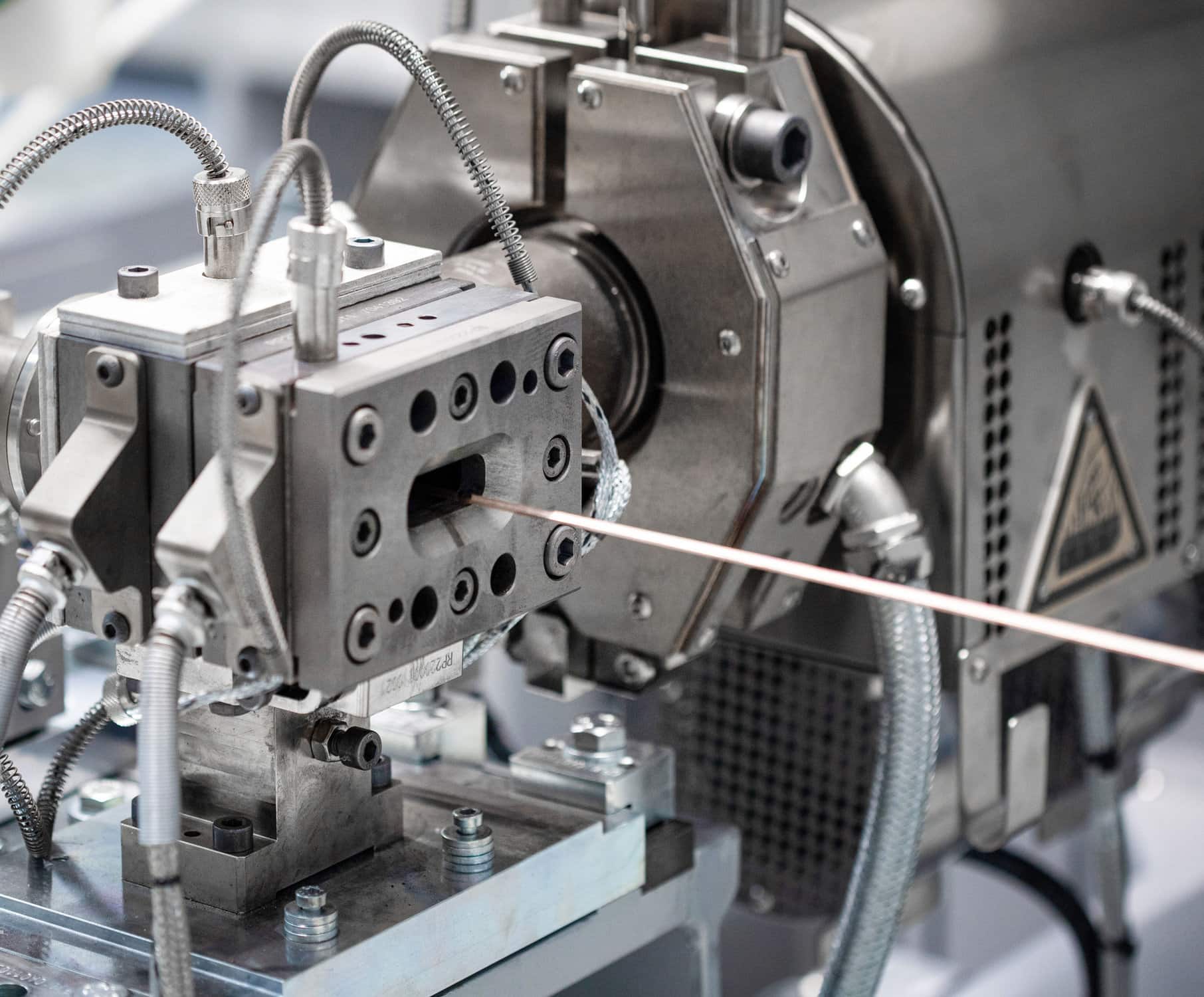

RA-I extrusion line for hairpin insulation

The compact RA-I insulation line is equipped with Rosendahl’s high-performance extruder technology and a specially developed crosshead for flat conductors. The complete conductor processing unit comes mounted on a base frame, well guided and stable, to maintain tight tolerances in production. From pay-off to take-up, every line component has been carefully synchronized to meet the high demands of the rectangular hairpin wire.

The processing of high-performance polymers requires a deep understanding of the underlying process, and equipment that meets the highest demands.

Technical data

-

Geared line speed up to 60 m/min

-

Insulation single layer

-

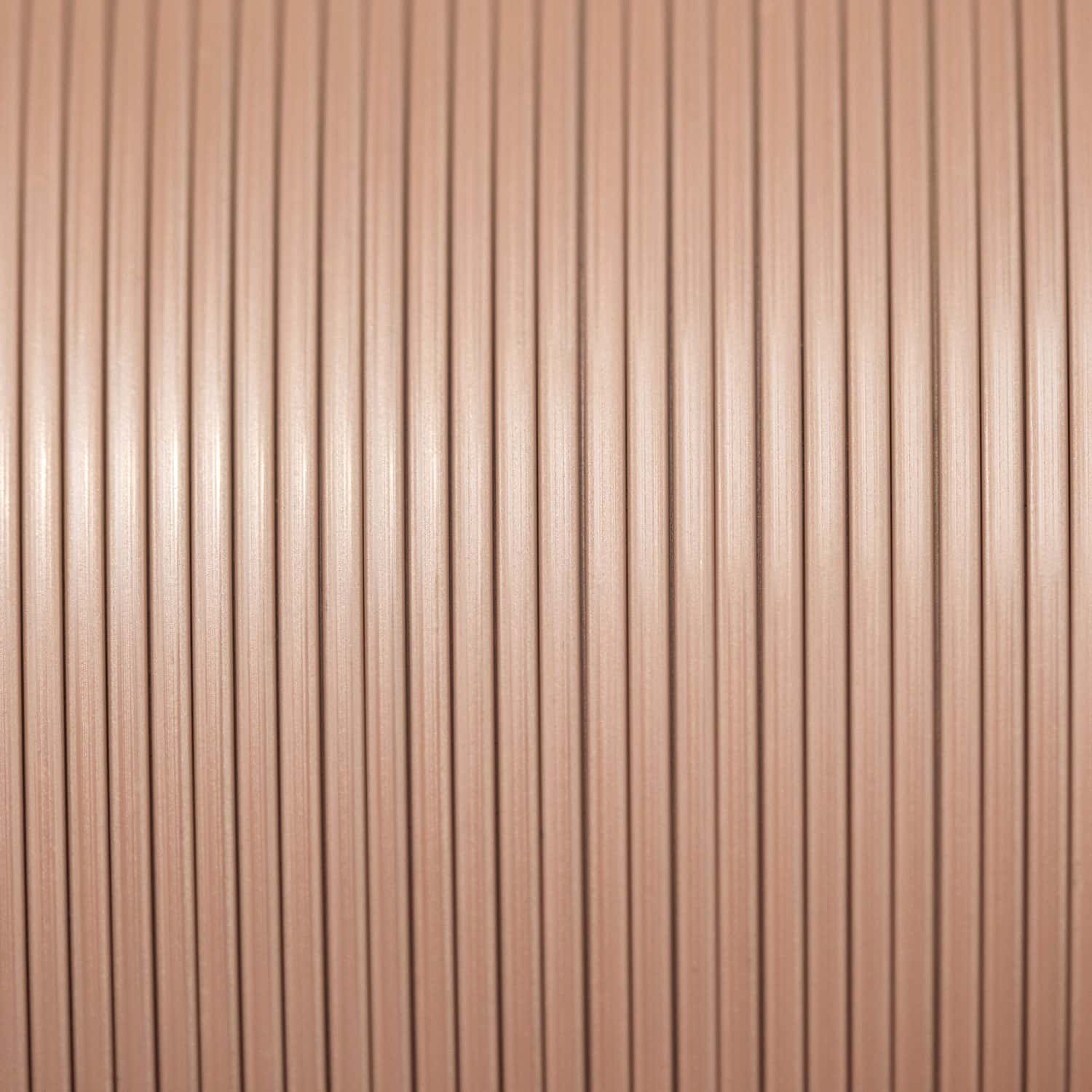

Insulation material high-performance plastic (PEEK, PAEK, PEKK, PSU, PPSU, PPS, TPI)

-

Wall thickness typically 0.1 - 0.25 mm

-

Cross sections typically 2 - 15 mm²

-

Thickness / width ratio 1:1.5 - 1:8

contact

get in

touch

with us

Do you want to learn more about this market innovation? Are you interested in finding out what modifications are possible to meet your individual requirements? Reach out to us. We will gladly answer your questions.