our sleeving & stacking machines

for industrial stationary and traction batteries

IPS 16

up to 18 pairs of plates/min

for PE sleeve and leaf-type separators

for industrial stationary and traction batteries

IPS 500/1000

up to 70 plates/min

for leaf-type separators

expertise

With our sleeving & stacking machines, you can produce large stationary and traction cells for DIN, BS, and BCI battery standards

- Different systems for processing PE and leaf-type separators

- Integrated visual quality check systems for cell configuration, lug shape and separator orientation

- Quick and simple change-over with a minimum of manual effort

Whether you want to produce cells with a leaf-type separator or sleeved plates – our most flexible machines can handle both.

Besides the different separator types, the following plates can be processed:

- positive tubular plates

- positive flat plates (core seal wrapped)

- negative flat plates

- ½ negative flat plates

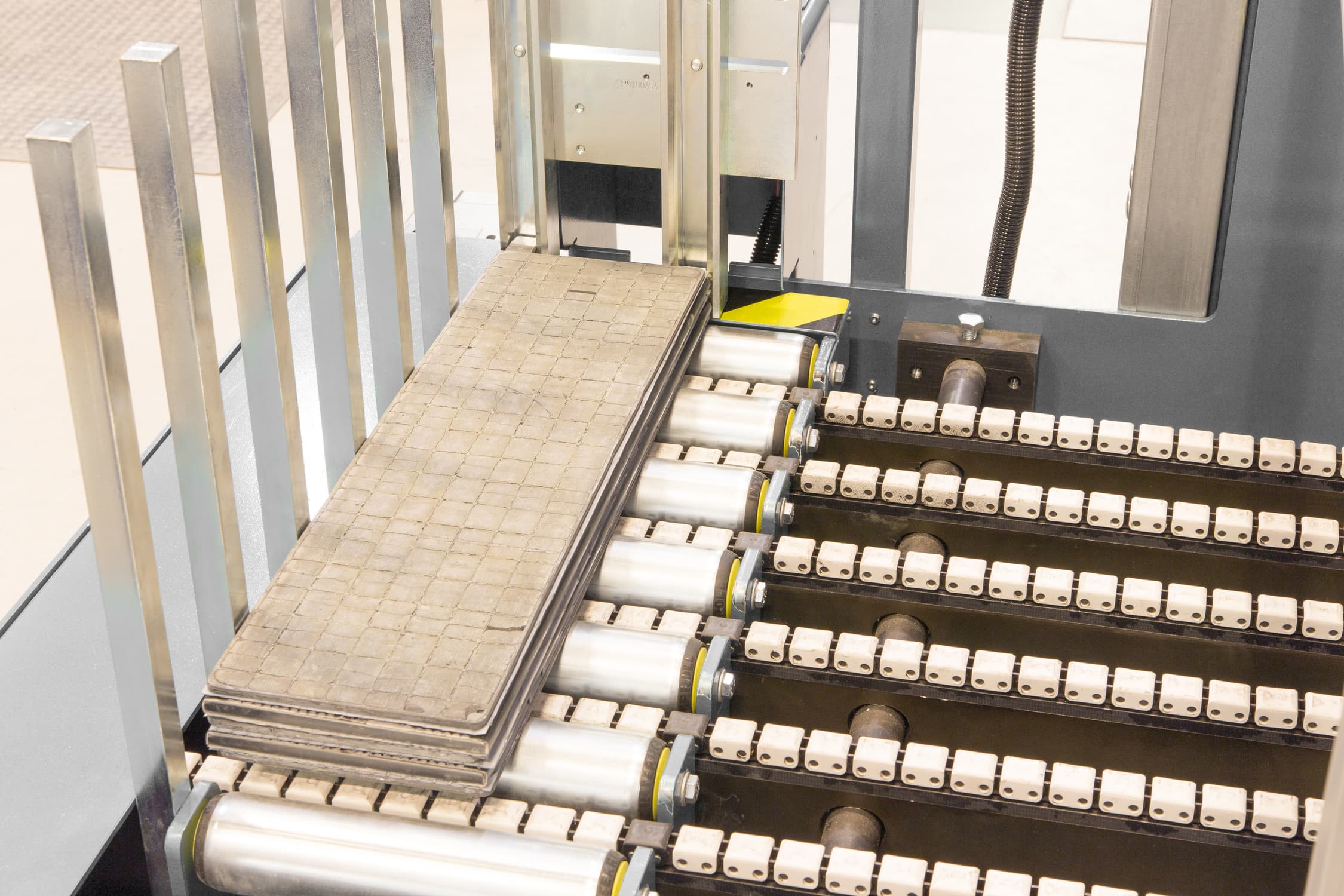

Each line component is also available as an individual machine. Upgrade your industrial cell production to your required automation level.

machine details

Learn more about our sleeving & stacking machine

To ensure high-quality cast-on-strap operation, you need perfect plate and lug preparation. This includes smooth plate feeding by vacuum handling and various lug preparation steps, such as:

- lug cutting (straight or V-shape shearing)

- lug milling

- lug brushing

- false lug cutting

for PE roll separator

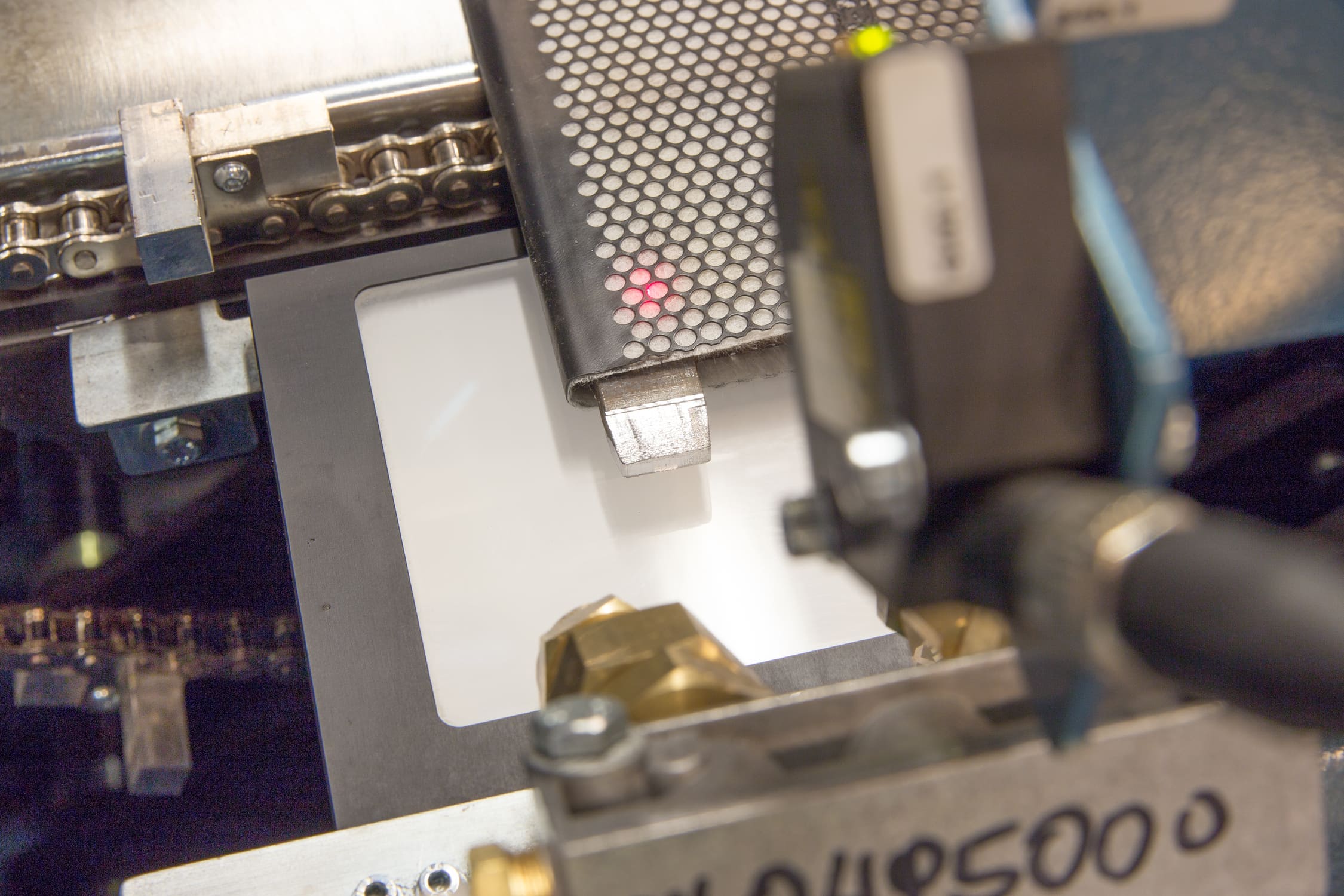

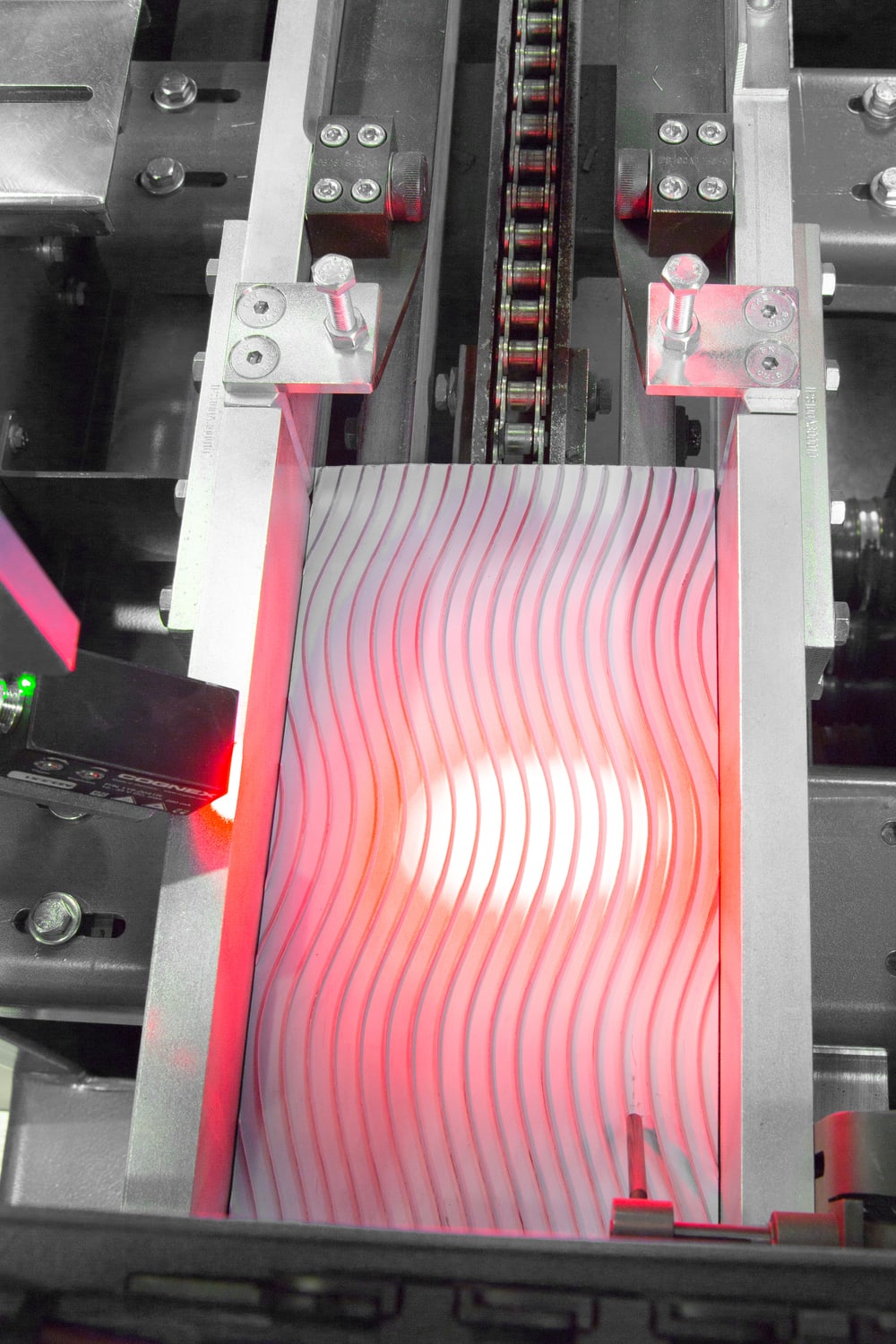

When it comes to producing sleeves, there are many steps that need to be followed. First of all, the roll separator is formed into an endless tube. After crimping the edges, the separator is cross-cut by a servo-driven system. Now you have perfect sleeves which are ready for plate insertion.

The separator is transported and positioned by means of vacuum feeding.

Precise plate and lug alignment ensures the best stacking results, which are essential for a high-quality cast-on-strap process.

Various available quality checks during the sleeving & stacking process guarantee the best possible results.

- lug shape check

- separator orientation check

- cell stack check

contact

get in

touch

with us