expertise for lithium-ion battery testing

Testing is an essential step when producing high-quality lithium-ion batteries. There are several inline and end-of-line tests, depending on your requirements.

visual tests

electric tests

leakage tests

visual tests

Component position:

- Checking of the positional tolerances of various components after assembly

- Exact position determination – tolerance compensation increases precision, especially for large components with large tolerances (e.g., battery pack)

Inspection of applied adhesive foils (shape from shading)

Component identification: reading barcodes, data matrix codes, etc. and entering them into a database

Surface inspection

Contour control: geometric inspection of contours, position recognition

electric tests

- OCV, ACIR, DCIR, EIS

- Isolation tests: cell to cell, cell/stack to housing

- High-voltage resistance tests

- Functional tests: CAN bus test, pulse power test with discharge to grid

leakage tests

Check the tightness of the module/pack housing or of the cooling circuit by

- Pressure test

- Sniffing test

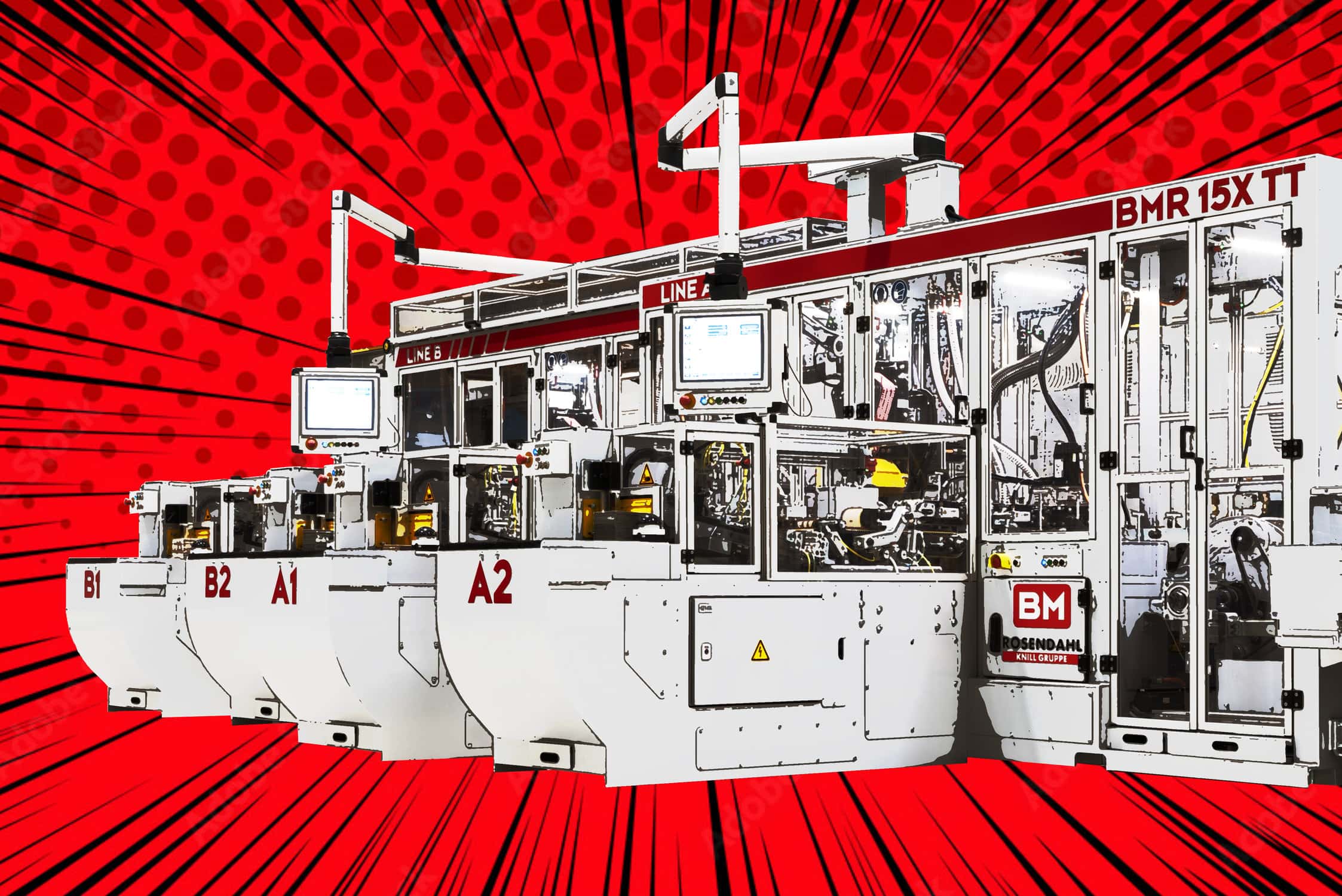

lithium-ion

production lines

News & Events

contact

get in

touch

with us

Rosendahl Nextrom is a global leader in battery, cable & wire and optical fiber production technologies whose goal is to connect your needs with our technology. Quality, customization, product know-how and close cooperation with our partners are our core values.