our cos machines

High quality machines result in high quality products

for automotive battery production

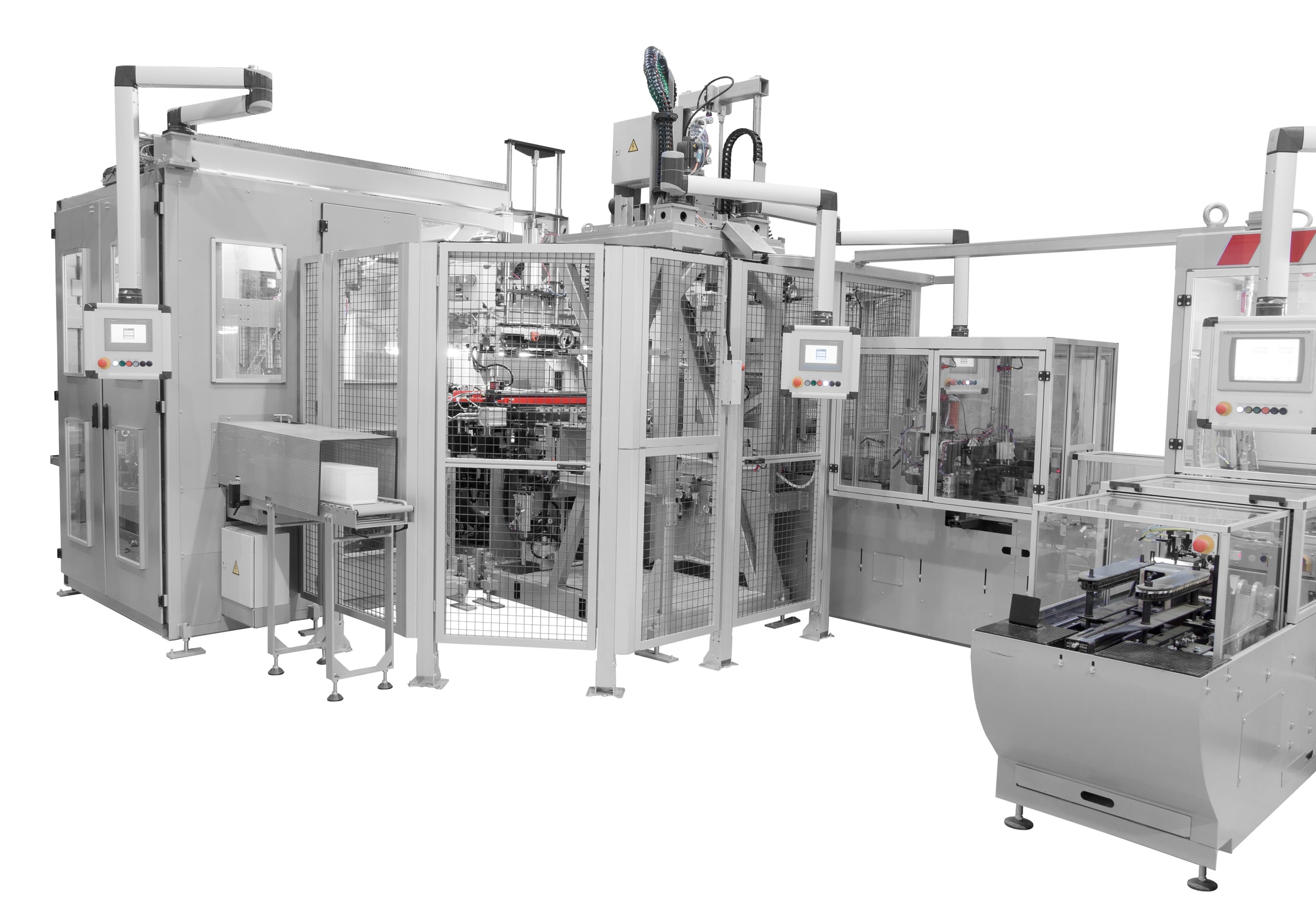

RoCOS X1

Processes up to 4.5 batteries/min (PE) and up to 4 batteries/min (AGM)

for truck battery production

RoCOS T1

for car and truck batteries, highly flexible for VRLA and flooded SLI truck batteries with an output of up to 3 batteries/min.

for industrial battery production

RoCOS S1

for telecom, stationary and traction batteries processing PE and AGM with an output of up to 2.5 batteries/min

expertise

Cast-on-strap (COS) machines. The heart of every battery production

With our RoCOS X1, you get the fastest cast-on-strap machine with a single mold in the world. Process up to 4.5 batteries/min with PE and 4 batteries/min with AGM elements. High quality machines result in high quality products. Special mold coatings and materials are available, therefore increased lifetime and additional lead savings possibilities are given.

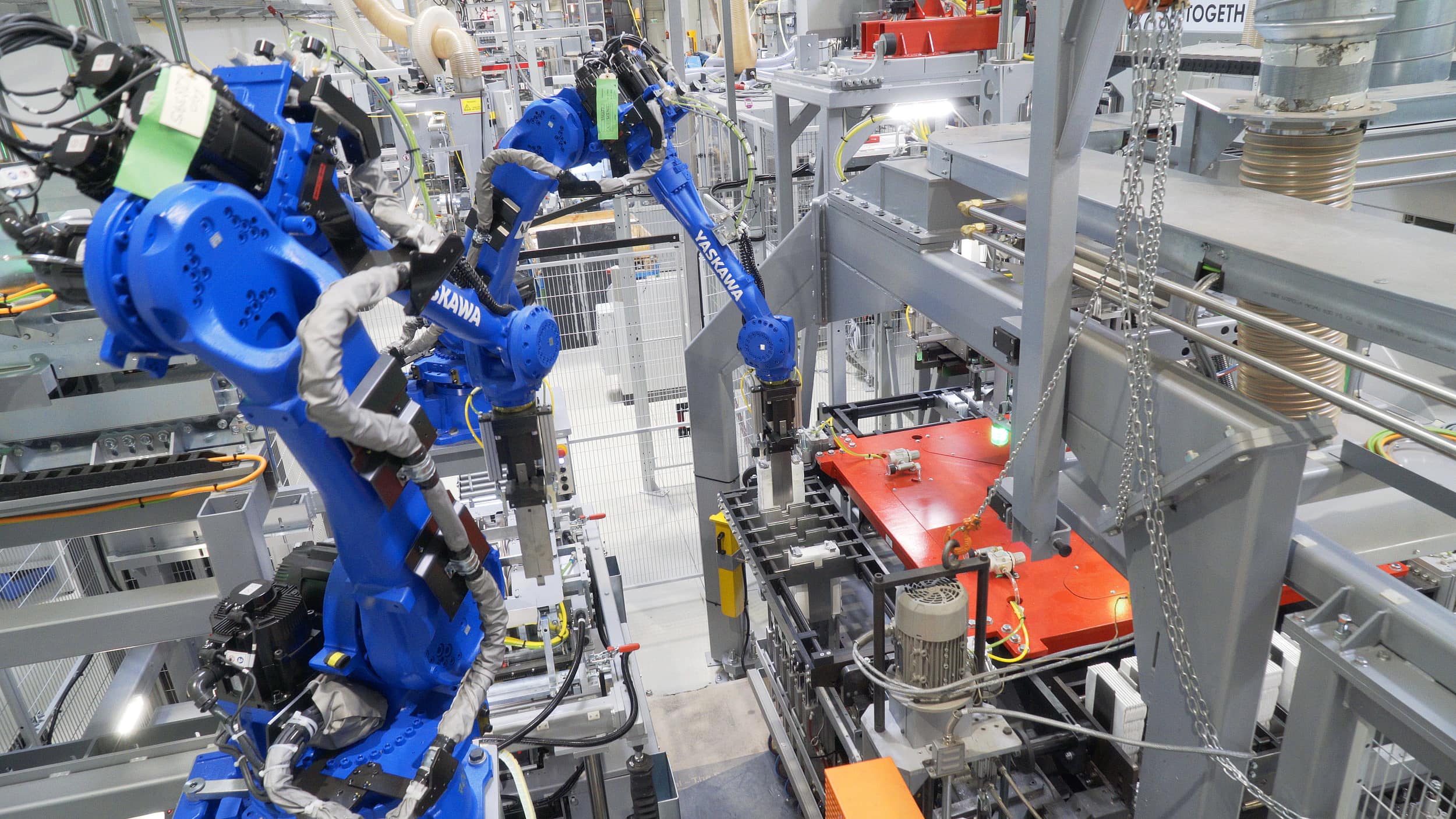

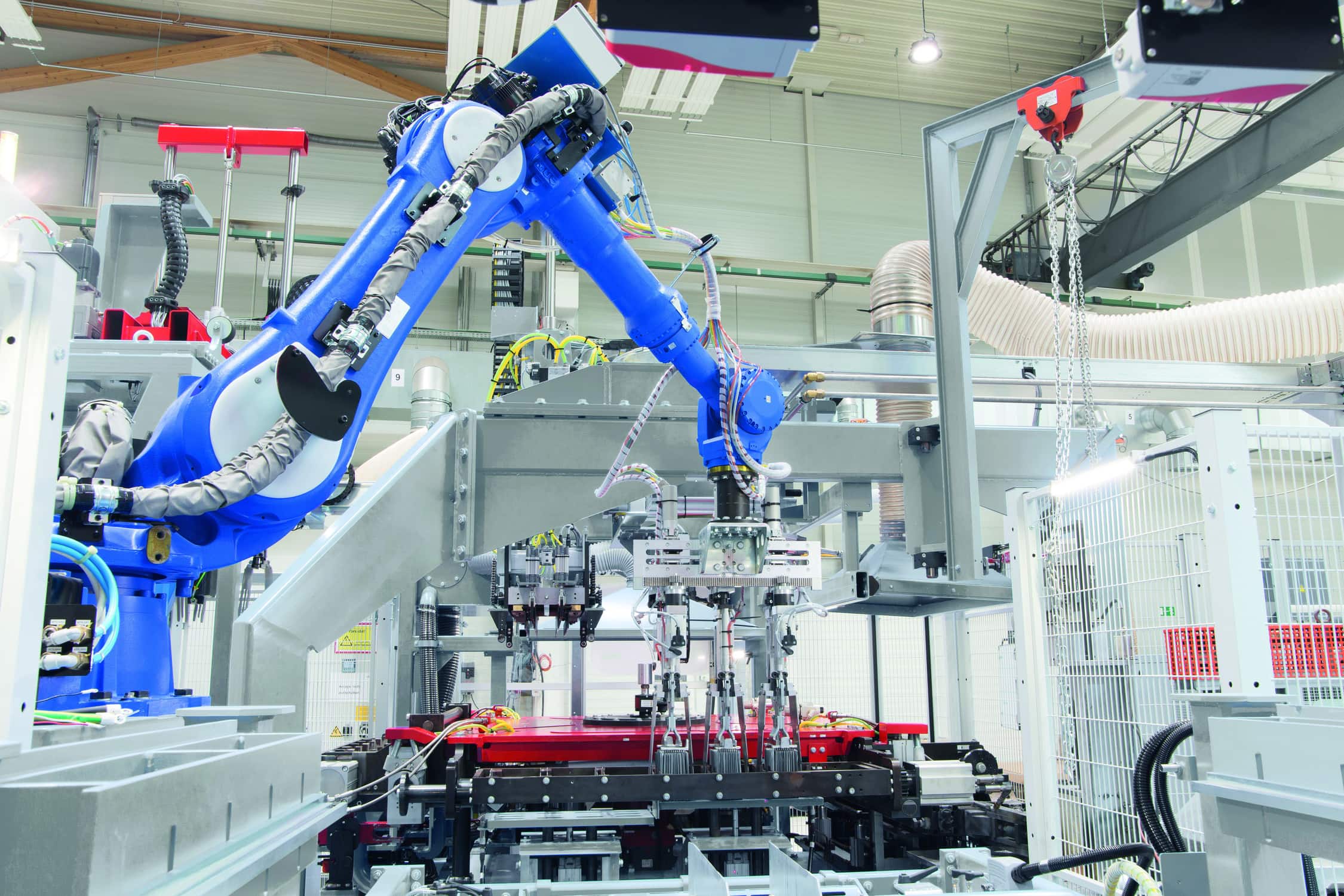

RoCOS is a flexible and high-quality machine for all battery types. Several options are available such as automatic robot loading, pole insert station, automatic pot changing system and data traceability.

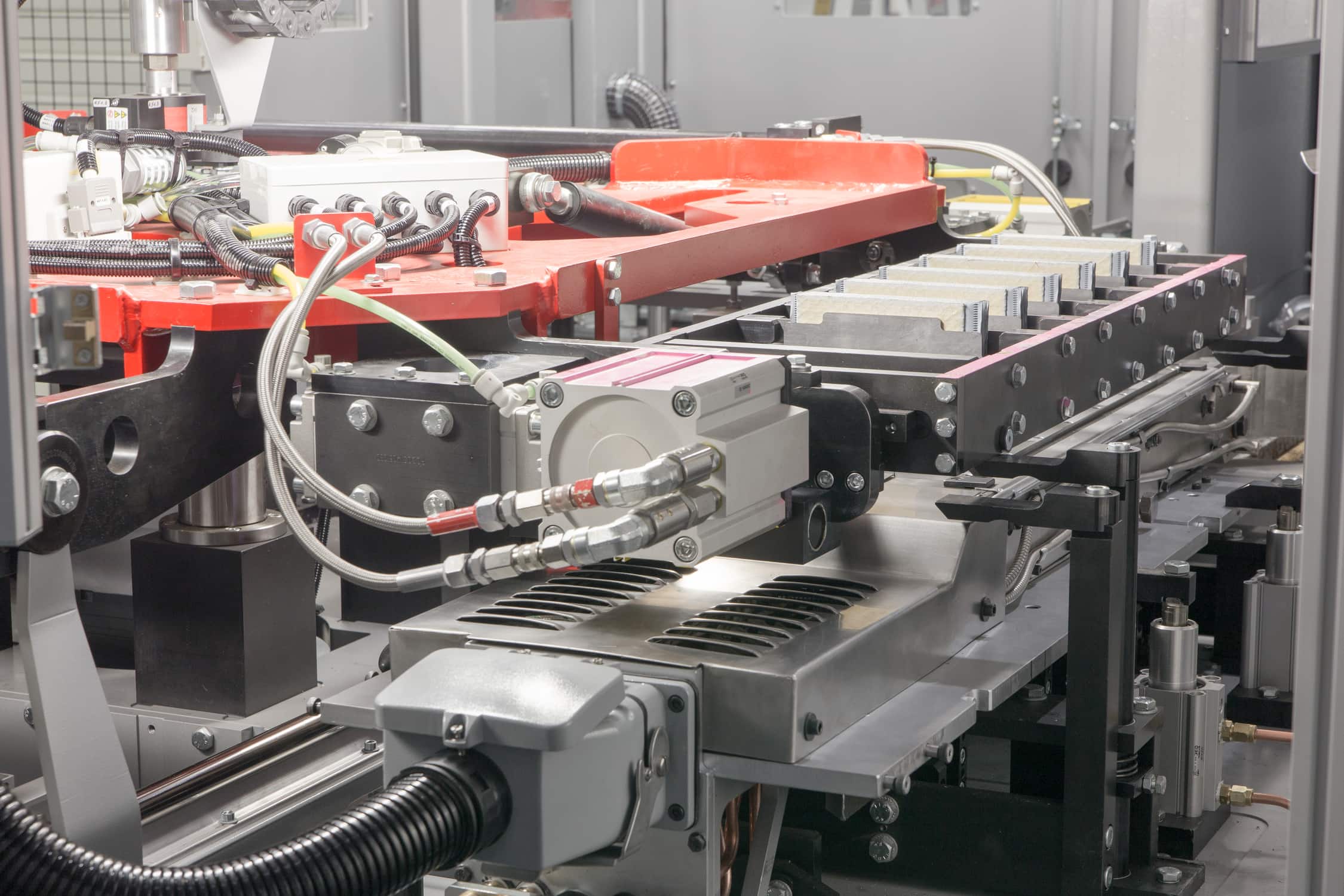

machine details

If you want to achieve high-quality straps, a chain of optimized processes must be followed

- loading & aligning of elements

- lug preparation

- casting

- unloading & boxing

Mainly driven by servo motors, our COS machines include many innovative features.

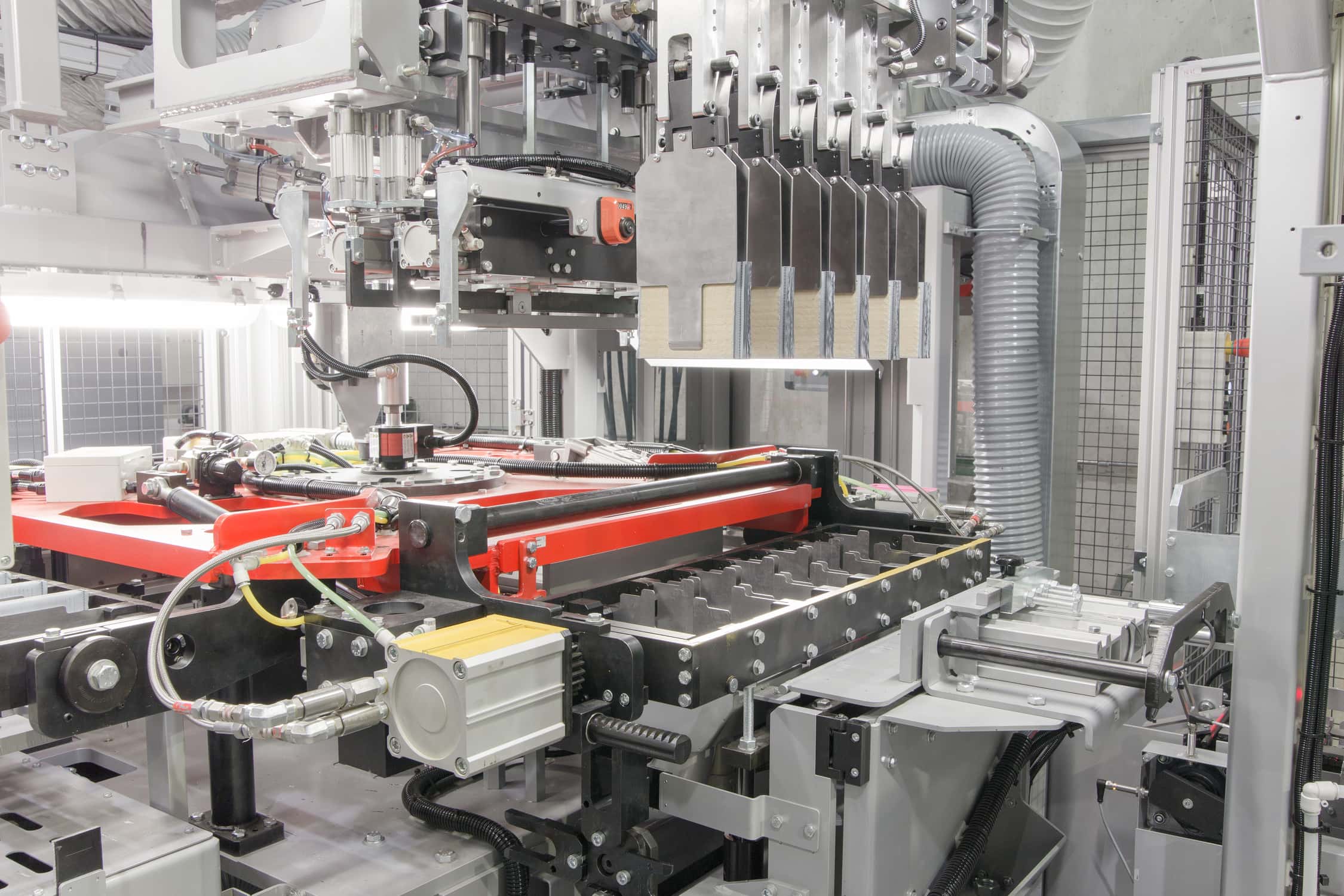

station 1

loading & aligning of elements

- swivelling arm or by robot (RLS)

- element aligning (vibration table, lateral, and on lugs)

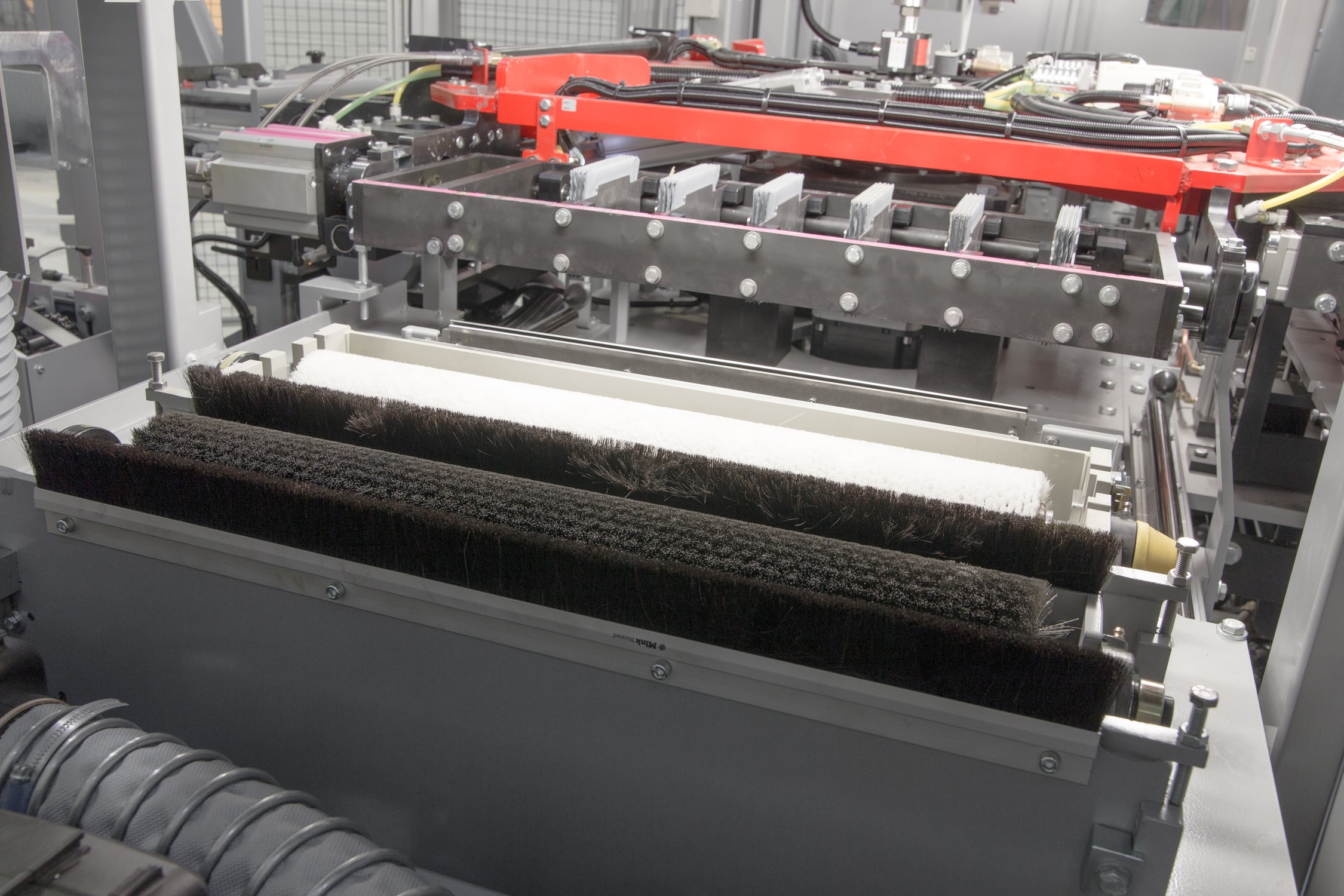

station 2

lug preparation

- brushing (optional)

- fluxing (continuous filling and level control)

- preheating (controlled drying, permanent temperature control)

- tinning (for VRLA batteries)

station 3

casting

- precise, stable, and lead-saving

station 4

unloading & boxing

- overhead gantry or robot system

- active boxing frame for PE

- compression unit for AGM

Did you know that only 0.5 mm thicker straps can result in up to 57 tons higher lead consumption per year?

With our mold technology, you can produce high-quality straps at a constant thickness – that helps you to save on energy and lead.

contact

get in

touch

with us