on-road transport battery assembly

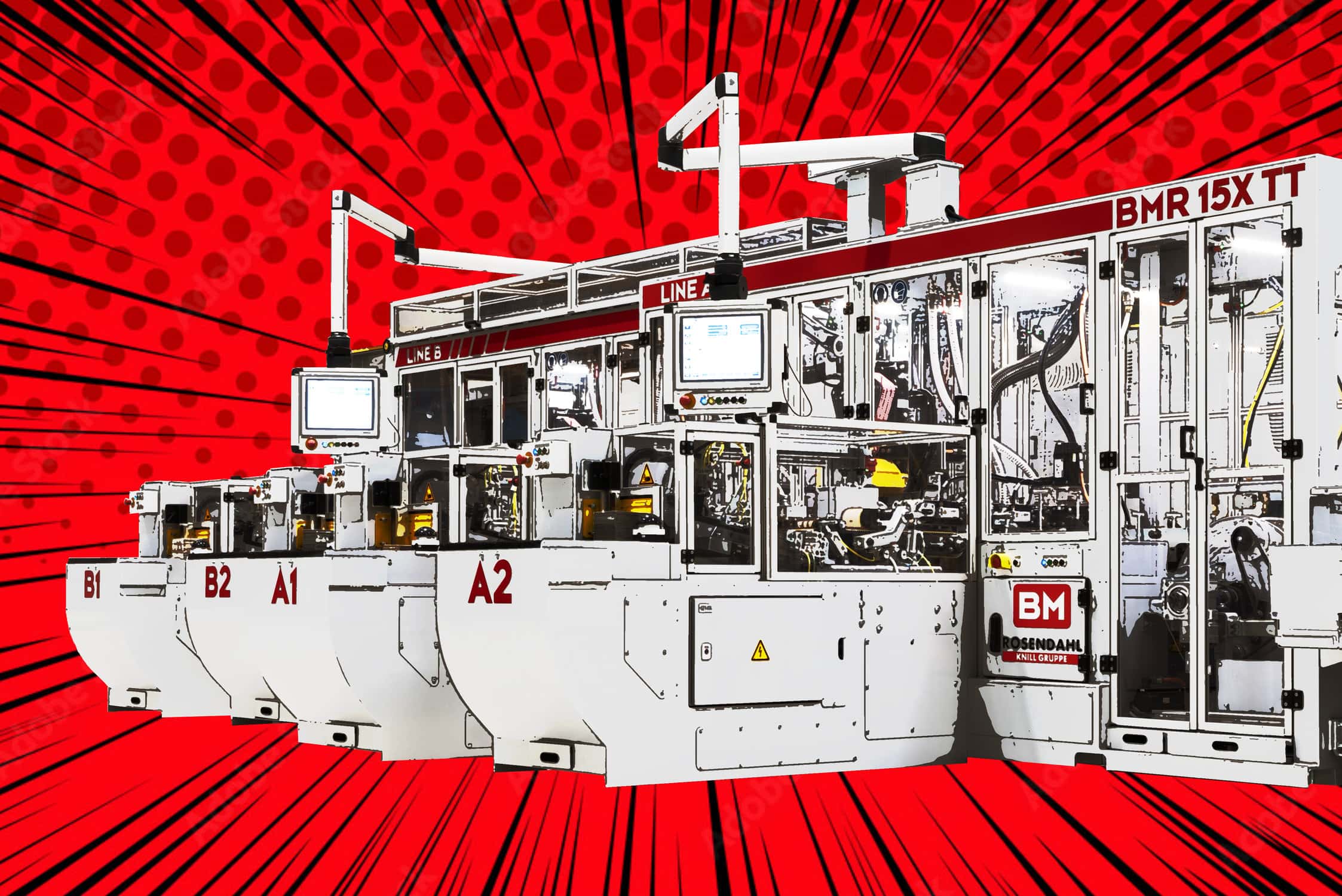

assembly lines with high output and a best quality standards

expertise

manufacturing solutions for transportation battery systems

The final applications in transportation are manifold. On BM-Rosendahl equipment assembled battery modules or packs go into

- EVs and PHEVs

- buses

- trucks

- two- and three-wheelers

Thus, our assembly lines are adaptable to different sizes and scales of the processable battery cells.

process know-how

processes in module and pack assembly

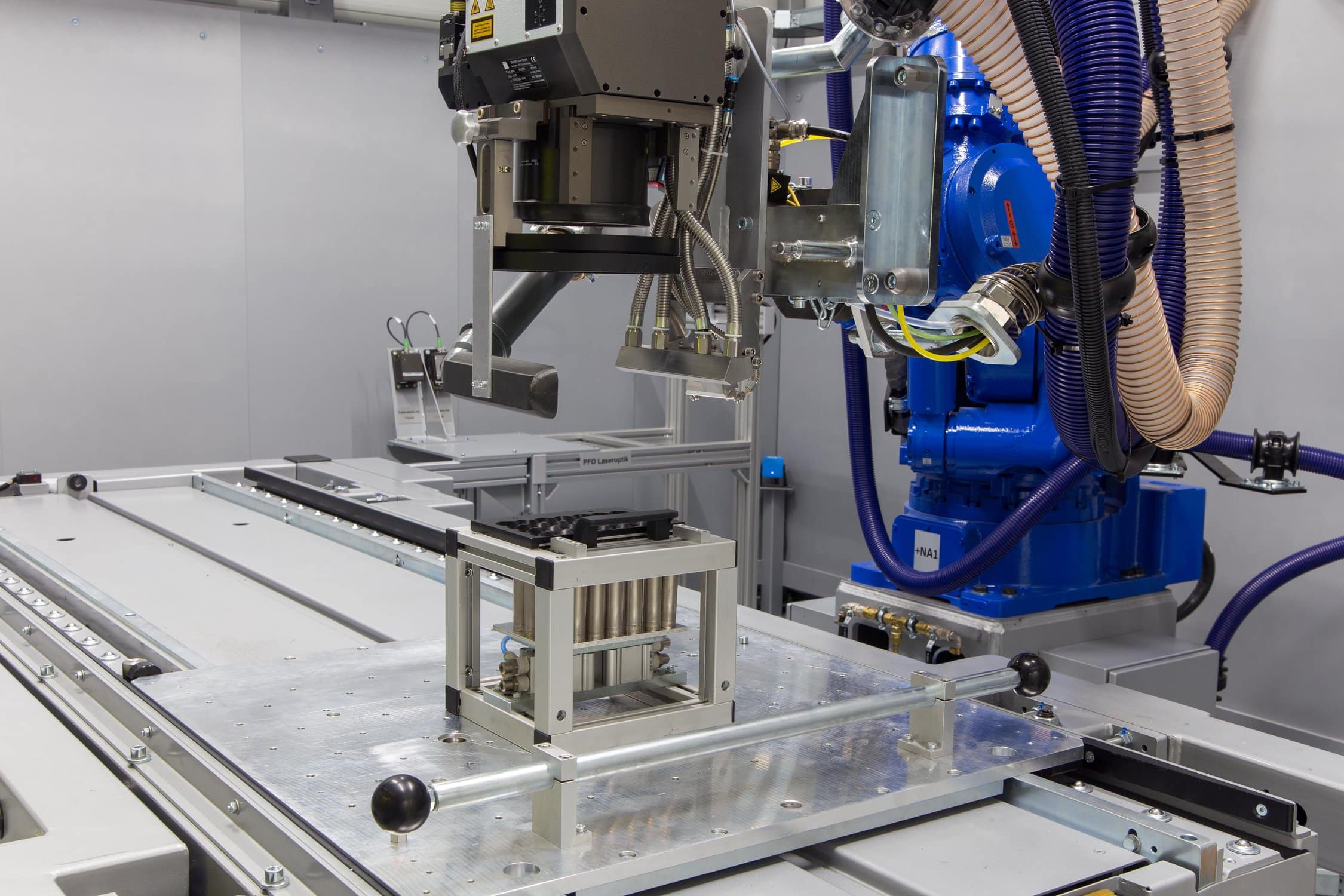

We cover all processes in battery assembly such as: initial testing and identifying, cleaning, cell handling, stacking, compressing, framing, welding, gluing, filling, checking, screwing EOL testing, etc.

Let us tell you more

New magazine "charge up" out now!

Take a look on our fresh ideas and our technology solutions for lithium-ion or lead-acid battery production! Our bi-annual magazine shares insigths on the market, our developments and what's good to know.

5-step checklist for your ideal production line

Are you planning to invest in lithium-ion or sodium-ion battery manufacturing equipment? We have developed a detailed 5-step guide to help you clearly define your vision of an ideal production line.

News & Events

contact

get in

touch

with us