Powering up your equipment

From delivery to full production

Commissioning is the final step before your cable production line goes live. At Rosendahl, we don’t just install equipment — we make sure your entire line runs reliably and delivers the quality you expect. We test all core components before shipping, guarantee performance for defined products, and stay on-site until everything works.

No time limits. No shortcuts.

What’s included in our commissioning service?

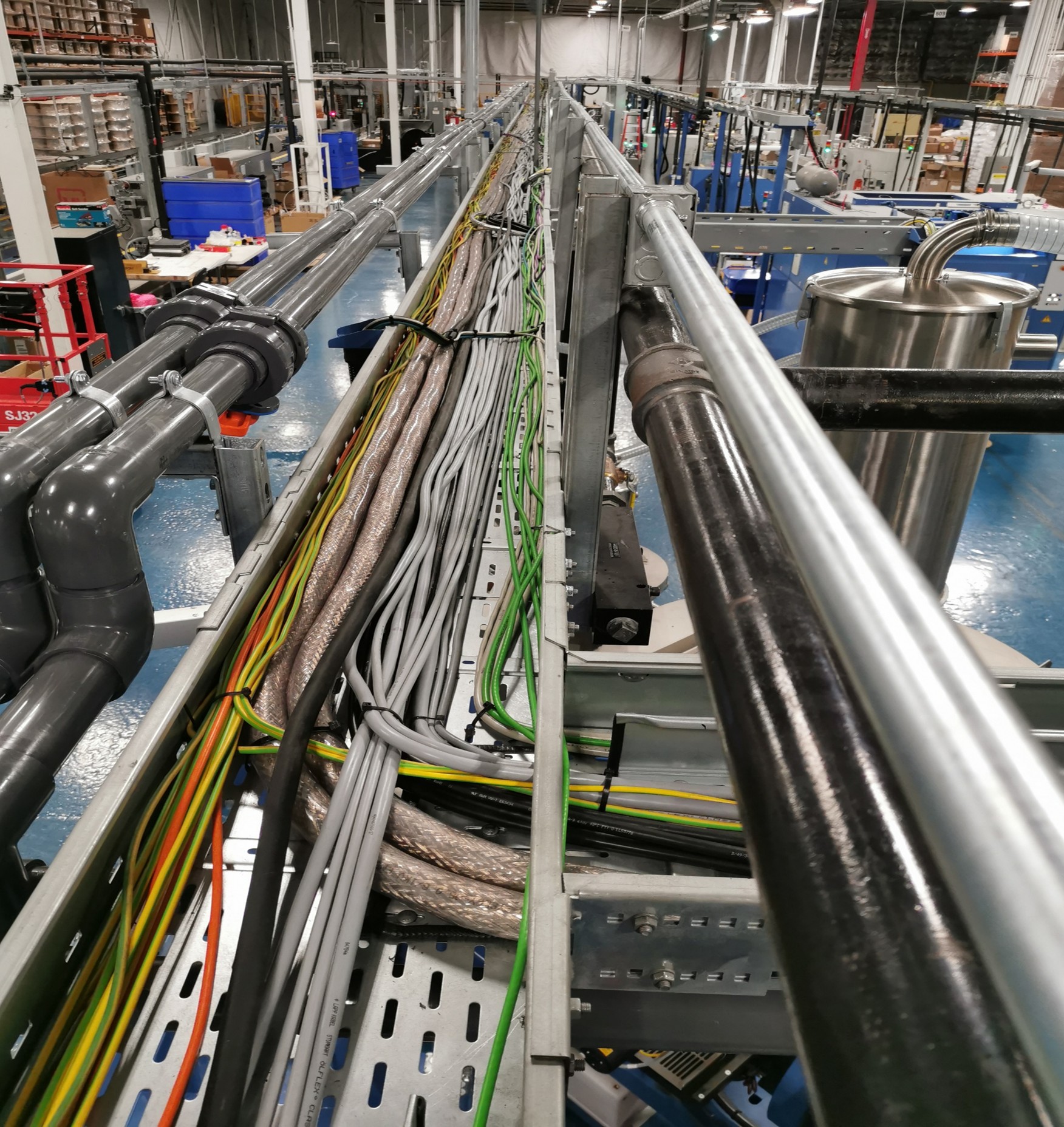

During this initial setup of your production line, we carefully position all machines and equipment on the production floor according to the layout drawing. After that, we connect the necessary compressed air and water supply to each machine.

When all machines are in place, we wire all line components supplied by Rosendahl Nextrom. The cables for your production line come pre-assembled to the required lengths, numbered, and clearly labeled with both source and destination. That saves time during installation and reduces the risk of errors.

Our engineers finalize electrical connections, power up the individual machines, and perform initial basic tests. In this phase, PLC parameters and drive settings are adjusted to prepare the system for operation.

Shortly after hardware commissioning has started, our software engineers come in. They activate the RIO line control, establish communication between components, and finalize the user interface according to your needs. They connect the line control system to your network, and – if required – integrate your ERP.

In this final phase, our process engineers fine-tune the line for full-scale operation. They adjust machine alignment, run functional tests, and carry out rewinding tests and trial runs together with the software and hardware team. Throughout this phase, our engineers also train your operators to independently run the line later on.

Once all quality criteria are met during the trial runs, the line is ready for the acceptance runs — the grand finale. Here, your operators take charge, with our engineers supervising the process.

After that, your new equipment and your team are all set to start production on their own. Make sure to address any remaining questions before our commissioning team leaves.

Once commissioning is successfully completed, our service team will take over ongoing support for your equipment.

Need recommissioning?

Sometimes it’s necessary to relocate an entire production line to a different hall, to a different facility, or even to a different country. We offer a professional relocation and recommissioning service to help you with the transfer from A to B:

- Careful mechanical and electrical dismantling at the old site.

- Supervising truck loading and unloading

- Hardware and process expert for recommissioning

- Setup at your new site

We ensure everything is correctly installed and fully synchronized at the new location. With all systems recalibrated and checked by our experts, production can resume — often even better than before.

Recommissioning is an ideal opportunity to carry out upgrades as well. Making the most of our experts’ presence on-site.

contact

get in

touch

with us