your set-up

to save energy

Take the next step towards more efficient and energy-friendly medium voltage cable production

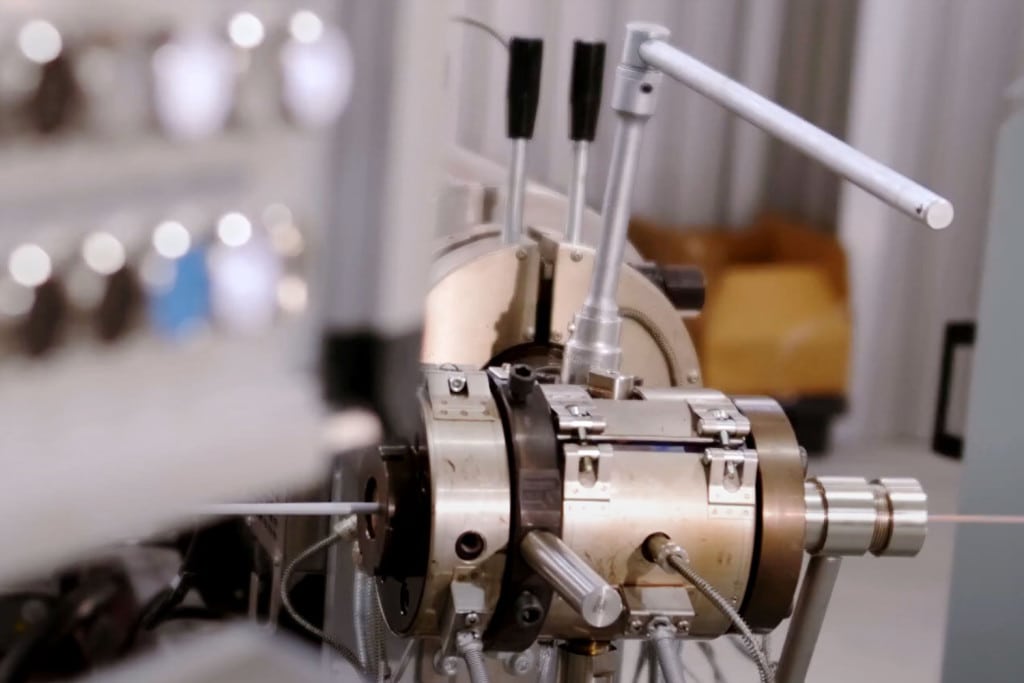

RoSET: Rosendahl superior extrusion technology

for medium-voltage power cables of up to 18/30 (36) kV

Get a full manufacturing concept for the efficient production of medium voltage cables from one source

This triple-layer insulation line is optimized for processing polypropylene. Like each of our production lines, it is 100% made in Europe in line with highest quality demands.

In-depth process

know-how

We have been researching the optimal processing of polypropylene-based compounds since 2011. Benefit from more than 10 years of intensive know-how in this special field.

PPC

material

starter package

Invest in a greener and more efficient production. Compared to XLPE, polypropylene combines several advantages that will take your power cable production to the next level, a much greener one.

all-in-one setup from one strong source

What makes RoSET so special?

Coming from one source, the whole RoSET setup is completely well thought out and all processes and materials are perfectly coordinated. That brings you many advantages as a producer.

Thomas Kulmer

your specialist for medium-voltage cable production machinery

Higher speed. Faster production.

Shorter lead-times

The thermoplastic material allows for higher extruder speeds, therefore higher line speeds can be used. The complex process of crosslinking is eliminated completely. No degassing, and no steam bath process is necessary. That results in much shorter lead times.

Produce sustainably

Energy-saving consumption

RoSET is a highly energy-efficient technology. The use of polypropylene (PP) instead of XLPE brings numerous advantages that translate into significant energy savings. That refers to the production of the raw material as well as to the entire cable production process with PP.

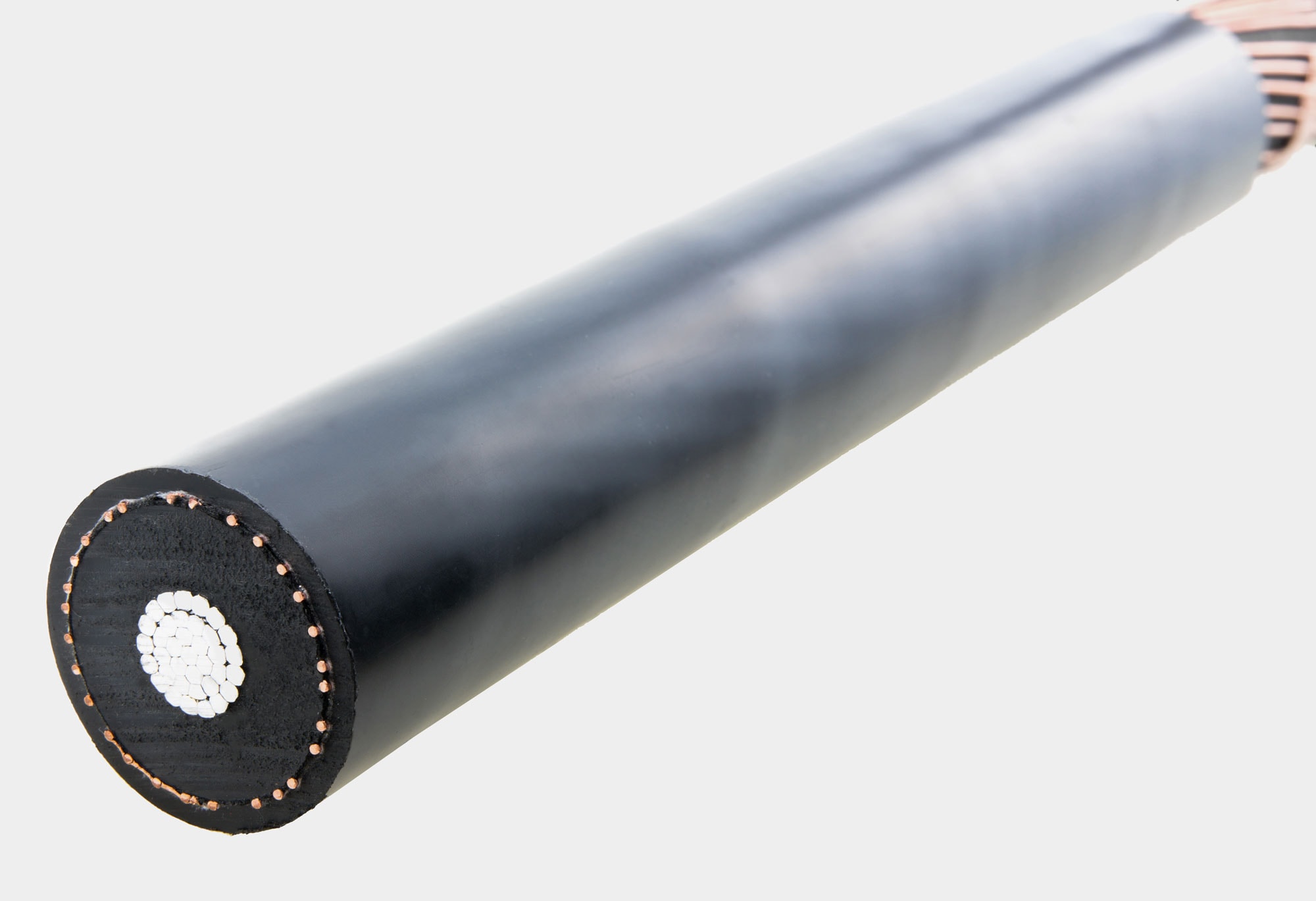

PP-based insulation for medium-voltage cables

Polypropylene has come to stay

XLPE, silane, and peroxide cross-linkable polyethylene insulation materials have been dominating the power cable market for decades. Now, polypropylene (PP) provides an equal or better alternative. The advantages speak for themselves:

- Higher operating temperature and speed

- Simplified production (no cross-linking)

- Re-useable thermoplastic material

- Excellent electrical behavior

technical data

RM-A Polypropylene Line

-

Cross section 50 – 800 mm²

-

Product range 1 – 18/30 (36) kV

-

Insulation material PP

produce LV

and MV cables on one line

The RM-A is a combined LV and MV power cable insulation line. It stands out due to its increased flexibility, high productivity, and excellent product quality. With this economic solution, it is possible to produce a large product range with limited production facilities, by processing low and medium voltage products on the same line.

- Tight tolerance and stable process control

- Smooth production with low scrap rate

- Large product range with various polymers

- Half the space required compared to a high-end CCV extrusion line

- Short down-time and change-overs due to special material handling

technical data

RM-A combined LV/MV insulation line

| LV | MV | |

|---|---|---|

| Cable standard | IEC 60502 | IEC 60502 |

| Cross section of the conductor | 16 – 300 mm² | 50 – 800 mm² |

| Insulation material | PE, PVC, XLPE-VISICO, HFFR, LSOH | Borealis LE4421M + LE4431M |

Tailor-made in Europe

according to your individual requirments

contact

get in

touch

with us

Are you looking into ways to make your power cable production more efficient? Do you plan on entering a new market or boosting your competitive position? Get in touch. We will be happy to go into more detail about our machines and solutions in a personal meeting.