what drives your production?

Master the challenges of today and tomorrow with our automotive wire and cable extrusion lines

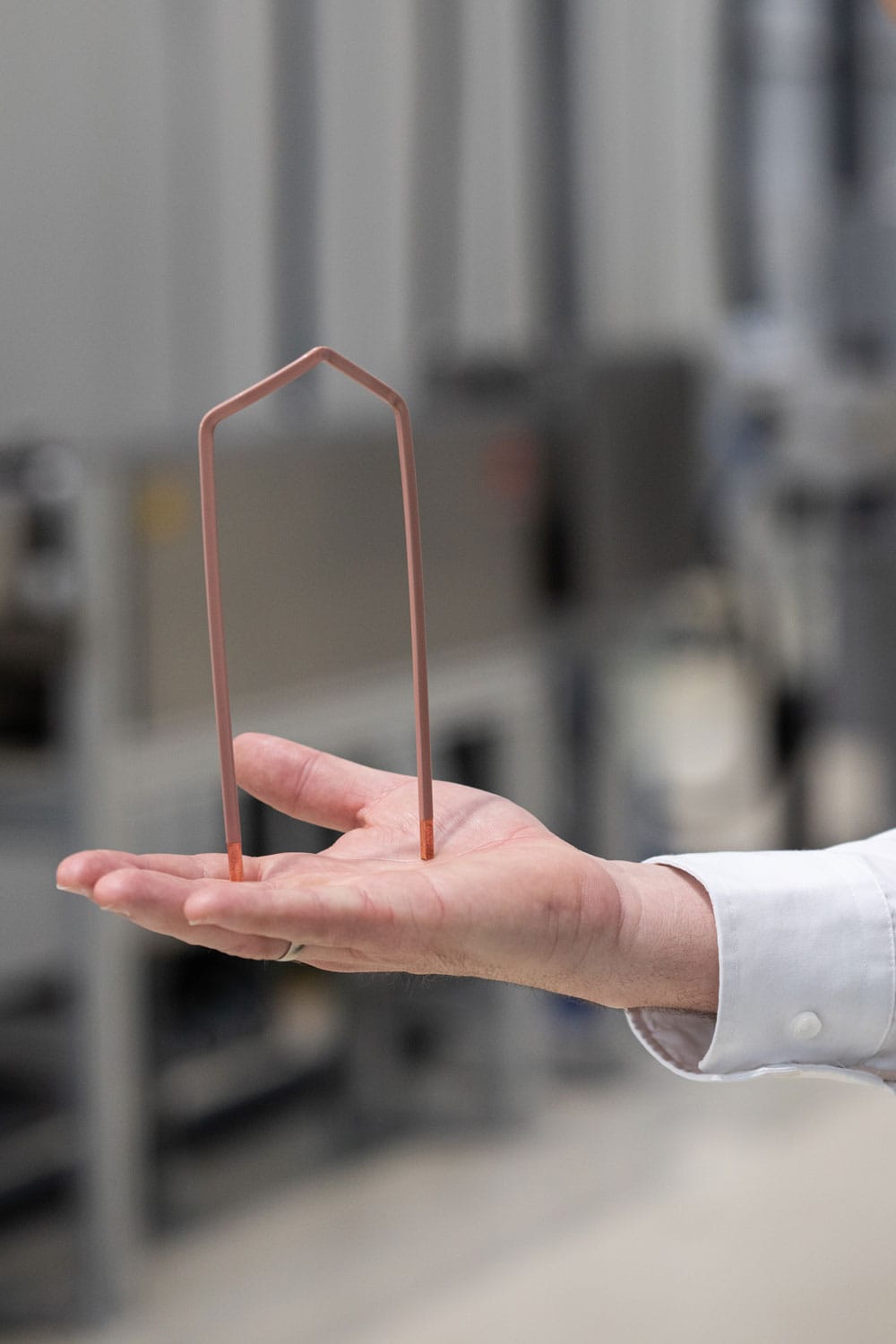

introducing a

game-changer for automotive:

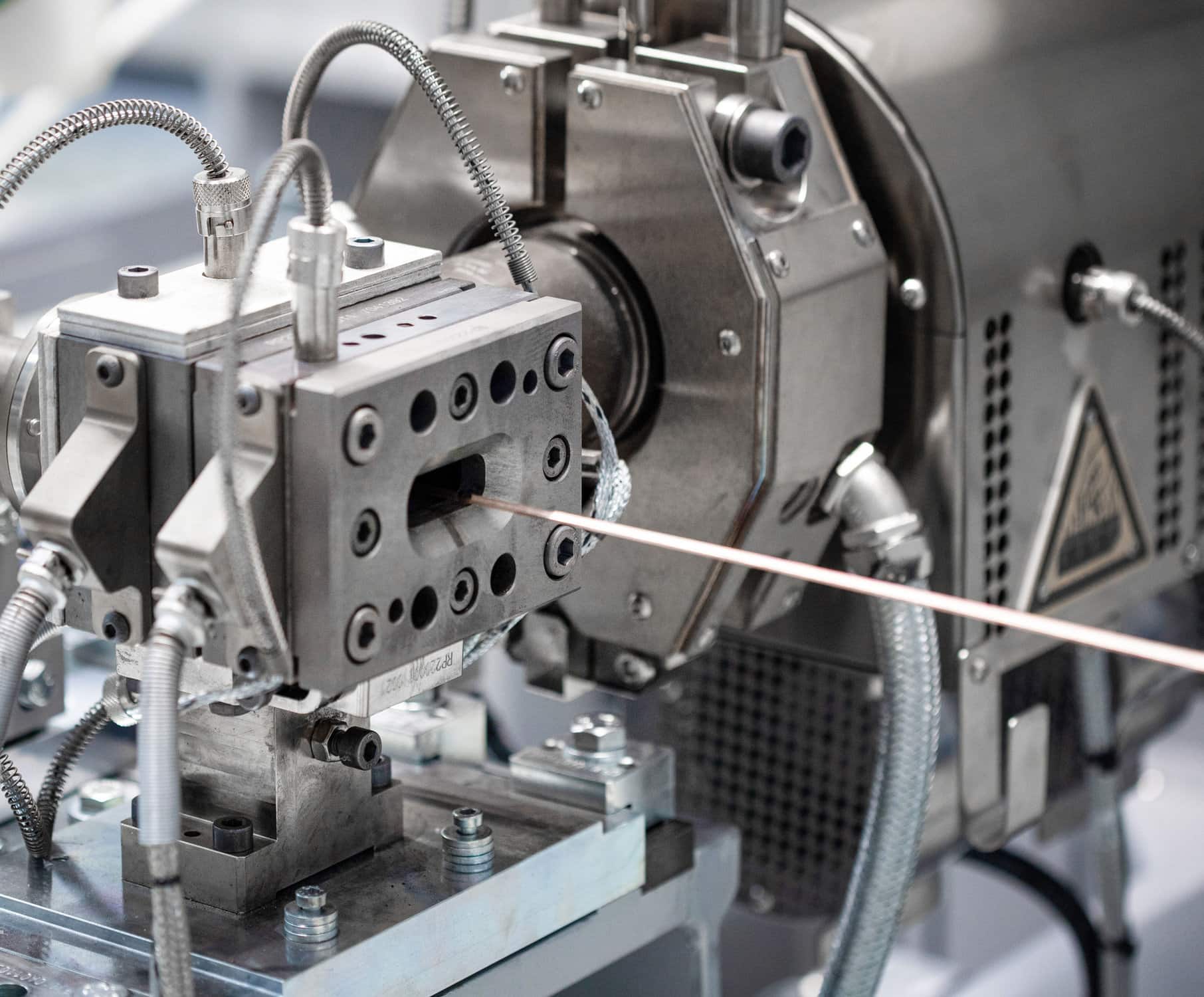

hairpin extrusion

After months of dedicated research and development, we proudly introduce the 1st industry-ready turnkey extrusion line for hairpin wire.

RA-I is an all-in-one insulation solution for the safe and efficient use of hairpins at 800V and above.

Expect outstanding product properties and a fast and reliable production process from A to Z.

automotive wire and cable extrusion solutions

With Rosendahl equipment for automotive wire and cable production, you are well equipped to master the challenges of today and tomorrow.

Fully electric, hybrid plug-in or autonomous driving? The automotive industry is competitive and constantly changing. New driving concepts are posing new challenges for the industry. With more and more sensor technology being installed in vehicles, the demands on cable and wire production lines are growing accordingly. We put all our expertise into developing machines that deliver high performance and excellent products.

Reliable machine setup with minimum downtime

Flexible production with small lot sizes

less is more

Save space, weight, and

costs with our efficient manufacturing concepts for automotive cables

A more complex harness does not necessarily have to result in increased weight or space required. We are constantly researching and developing to make cable production even more efficient.

Reduce wire

weight

by means of smaller cross sections

Reduce wire diameter

by means of compacted conductor design

Reduce wall thickness

with the help of high-performance insulation

Reduce your CO₂ footprint

thanks to highly efficient production technology

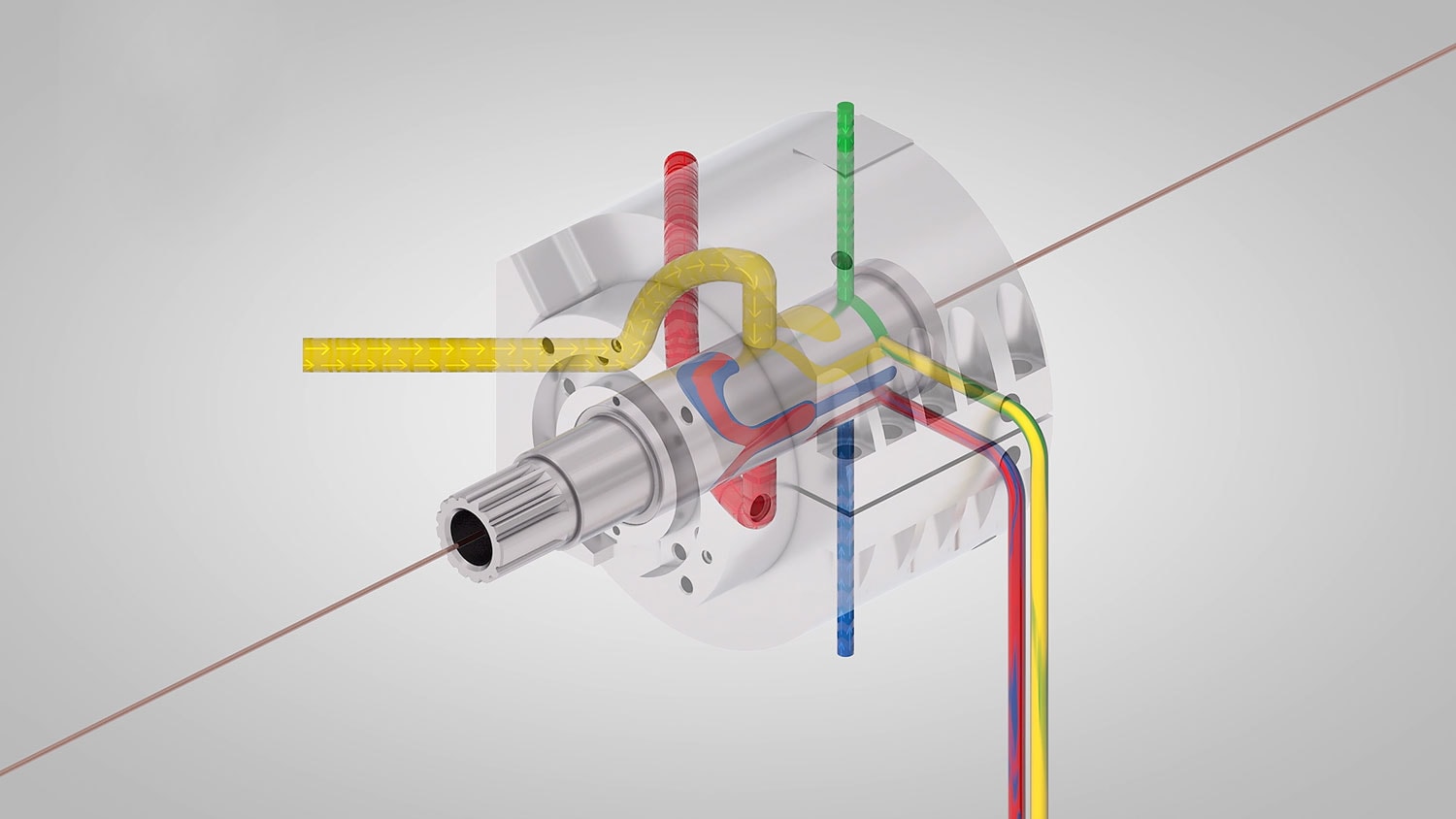

ROCOMAT quick color-change system

From red/blue to yellow/green in 0.3 seconds

With the unique ROCOMAT system, we integrate a color-change function directly into the crosshead. That reduces the color-change volume to an absolute minimum and achieves the shortest color-change length in the industry.

VS SK-410-C Color-recognition system

Monitor your production 24/7/365 and reduce claims

Detecting color variations at a speed of 2,000 m/min seems impossible? It isn’t. With this innovative 360° sensor system, you can detect color deviations unperceivable to the human eye.

utmost quality is our aspiration.

Tailor-made manufacturing solutions for automotive wire

Get the most suitable equipment to produce worldwide standardized products for the automotive industry.

Your production line will be customized to meet all required global standards, as well as specific automotive brands’ requirements regarding electrical behavior, geometrical properties, or mechanical and temperature resistance.

- European Specification: ISO International organization for standardization

- U.S Specification: SAE Society of automotive engineers

- Japan and Asia Specification: JASO Japanese automotive standard

Christoph Faustmann

your specialist for automotive wire manufacturing solutions

fast. reliable. smart.

Rosendahl production lines for automotive wires and cables

RA-A

Insulation

Line for Automotive Wire

RA-I

Extrusion

Line for High-Temperature Materials

RN-Z

Extrusion

Line for Silicone Materials

Sheathing Line for Automotive Wire

Datacom Line for Automotive Wire

Hairpin Insulation Line

Bus Bar Insulation Line

overview

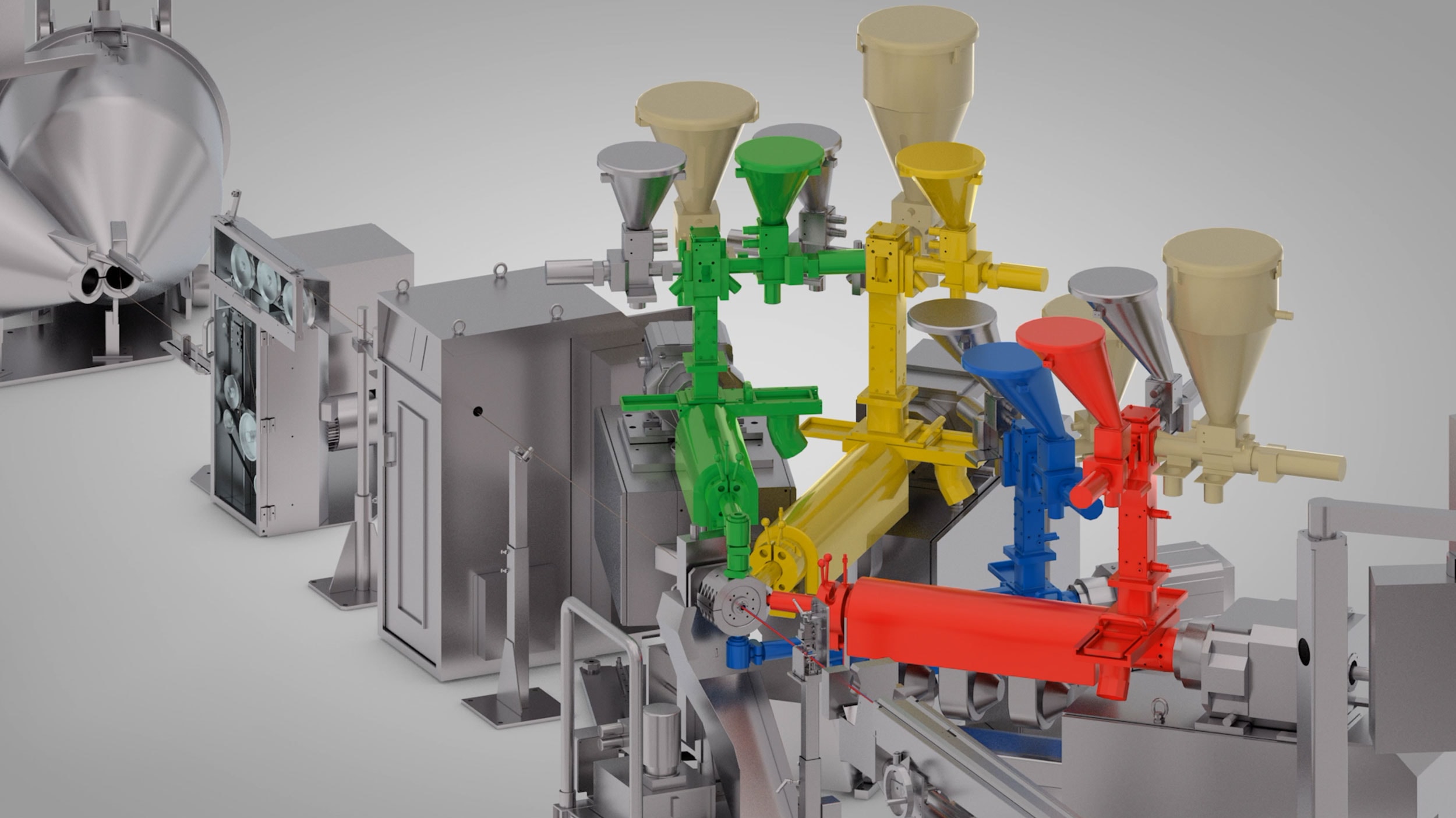

Rosendahl line configurations for automotive wire and cable production

full flexibility for your products

| Product size | Maximum speed | Materials | |

|---|---|---|---|

| Small cross-section line | 0.08 – 1 mm² | 2,400 m/min | PVC, PP, PE, XLPO/XLPE, TPE, … |

| Standard extrusion line | 0.22 – 8 mm² | 1,500 m/min | PVC, PP, PE, XLPO/XLPE, TPE, … |

| Big cross-section extrusion line | 10 – 240 mm² | 500 m/min | PVC, PP, PE, XLPO/XLPE, TPE, … |

| Silicon rubber line | 10 – 240 mm² | depending | |

| Sheathing line | 5 – 36 mm | 500 m/min | PVC, PP, PE, XLPO/XLPE, TPU/PUR, TPE, … |

| High-temperature material line | 0.13 – 4 mm² | 500 m/min | FEP, ETFE, PFA |

| Datacom line | 0.13 – 4 mm² | 1,500 m/min |

Solid PE, Solid PP

Cell-PE*, Cell-PP* *chemically and physically foamed |

| Bus bar insulation line | 25 - 300 mm² | 150 m/min | PVC, PA12, TPE |

| Hairpin insulation line | 2 - 15 mm² | 60 m/min | High-performance plastic (PEEK, PAEK, PEKK, PSU, PPSU, PPS, TPI) |

Produce these and more products for the automotive industry on tailor-made equipment by Rosendahl

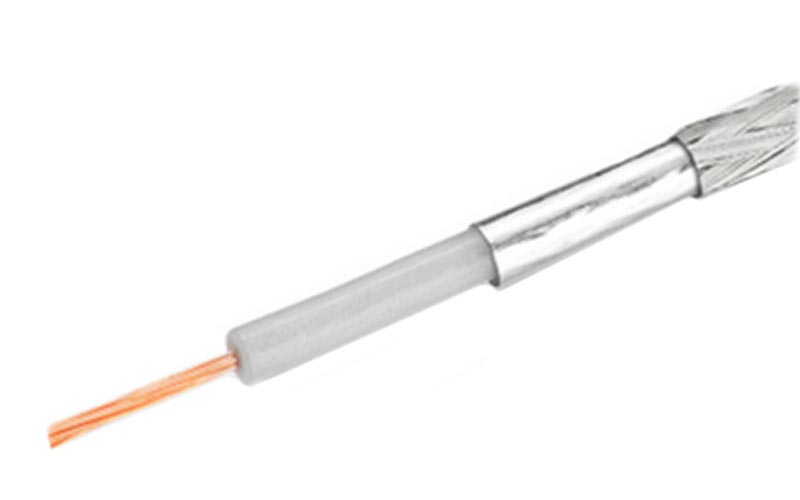

Single

wires Small conductor size

0.08 – 8 mm²

Temperature range T1 – T8

With improved abrasion resistance

Huge variety of different color combinations

Flexible production with small lot sizes

Single

wires Big conductor size

10 – 240 mm²

Temperature range T1 – T6

High-voltage cables 600V AC / 900V DC

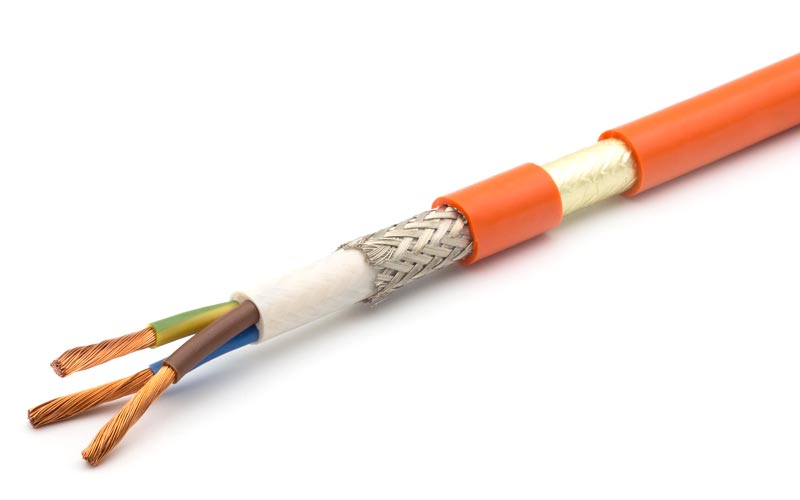

Multicore

wires

Outer diameter 5 – 36 mm

For eccentric cable construction

For high demand for roundness

TPU sheath for improved abrasion resistance

With different surface textures from shiny to matt

Customized production lines for automotiv cables & wire

Ask us for a tailor-made solution specially for your wire design

contact

get in

touch

with us

Contact us if you are interested in high-performance equipment for automotive cable and wire production. We will be happy to answer your questions.