extrusion crossheads

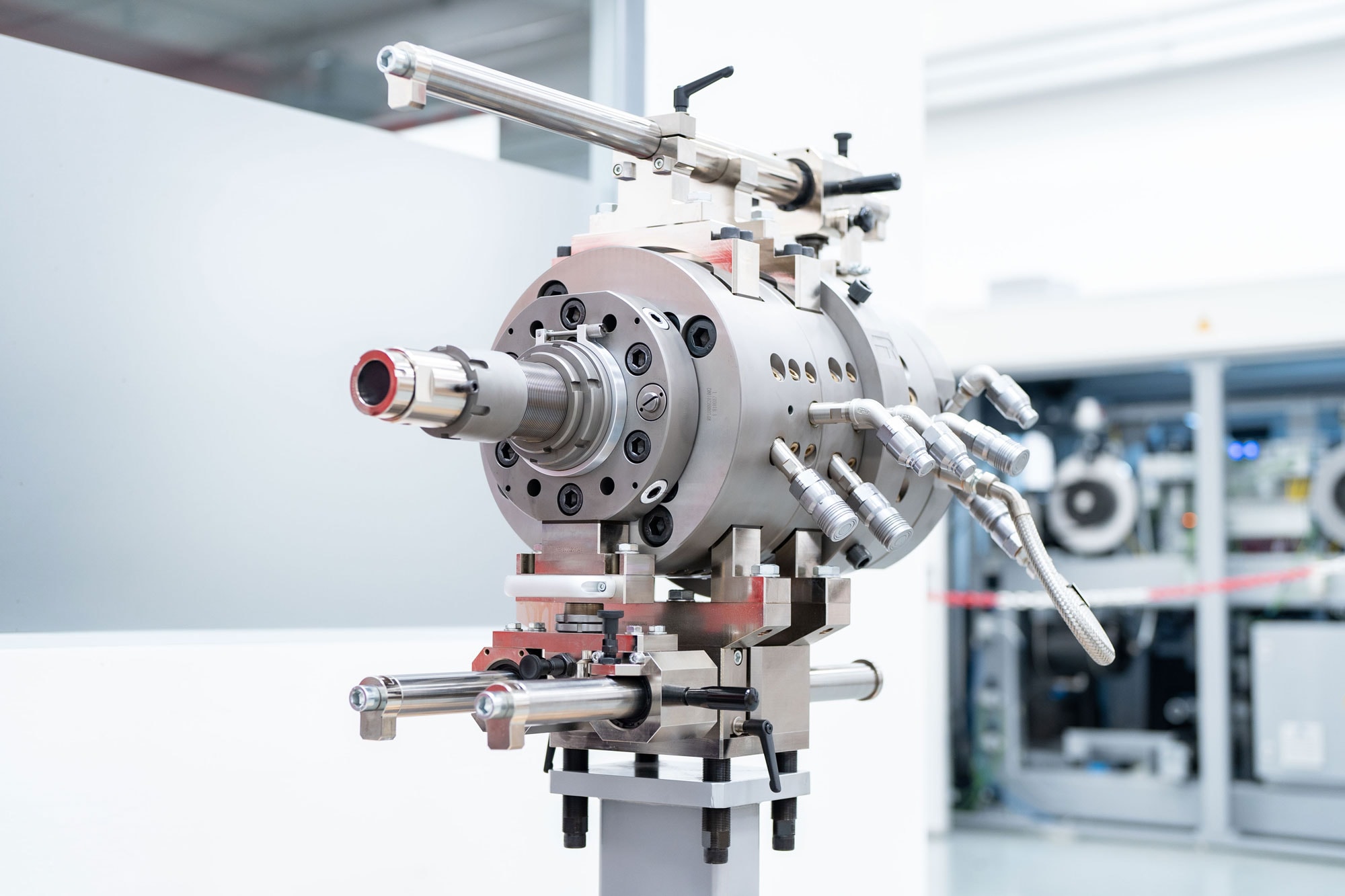

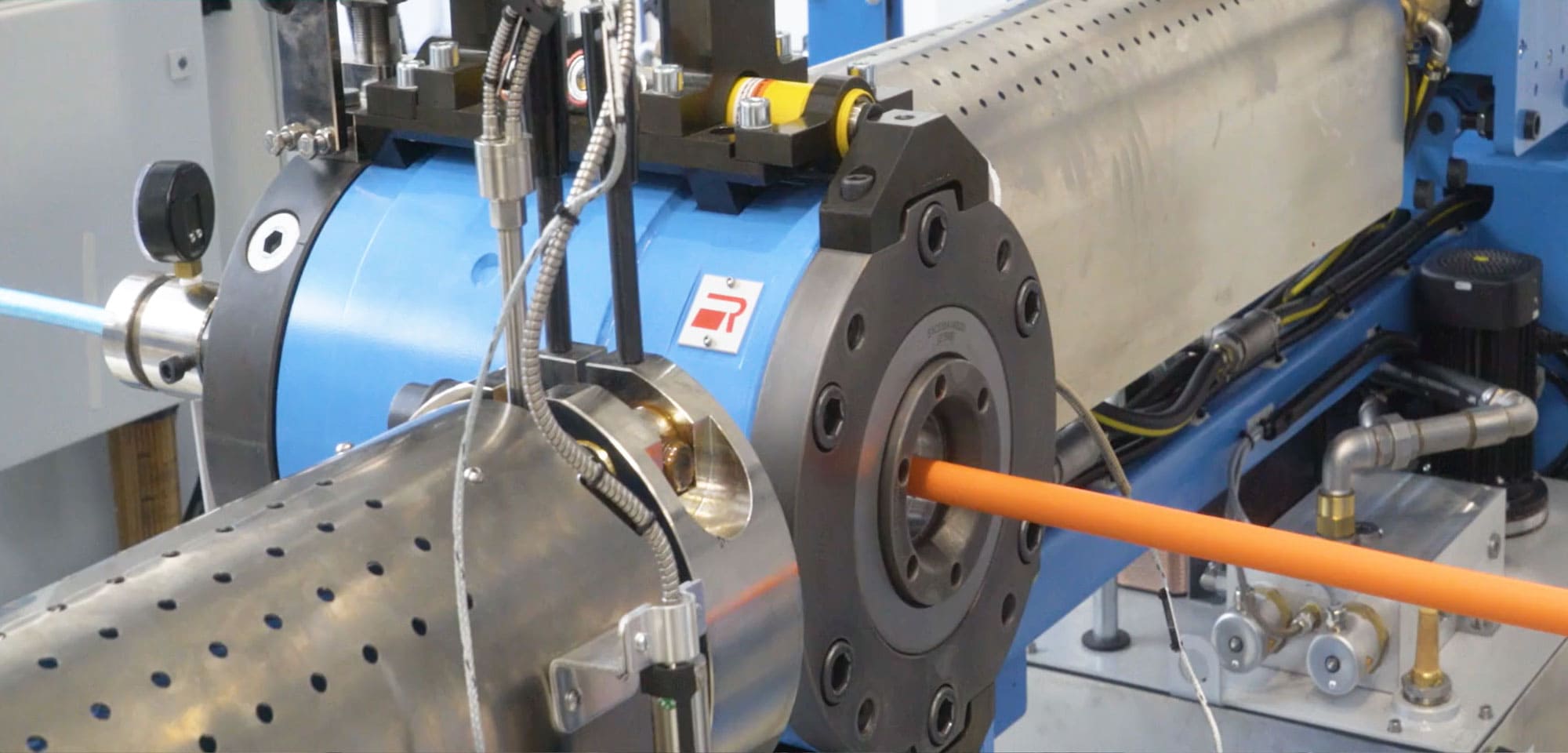

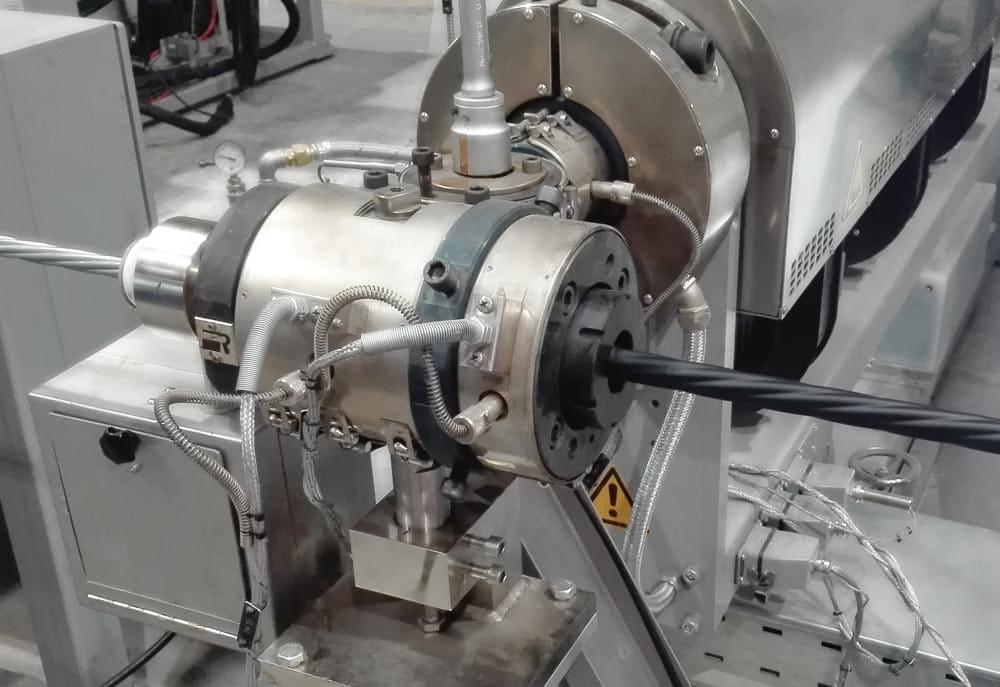

Get the latest crosshead technology for small to big diameters with our Rosendahl RX crosshead series.

Rosendahl quality

What makes a crosshead

a good crosshead?

A high-quality cable is the result of many different factors. Luckily, we master them all. Our strength is the extensive process know-how we have at Rosendahl Nextrom. We are specialists for the entire extrusion process and can therefore optimally adapt the crosshead to your individual requirements. Because only when everything is perfectly coordinated you get a perfect result in the end.

With our Rosendahl Crosshead Series RX we offer a wide range of crossheads for numerous applications:

- core diameters ranging from 0.03 to 180 mm

- solid and foamed polymer materials

- single- or multi-layer extrusion

All the crossheads are offered as single machines and also in complete lines and fit every kind of extrusion line.

Benefit from many decades of comprehensive know-how

our new

co-extrusion

crosshead

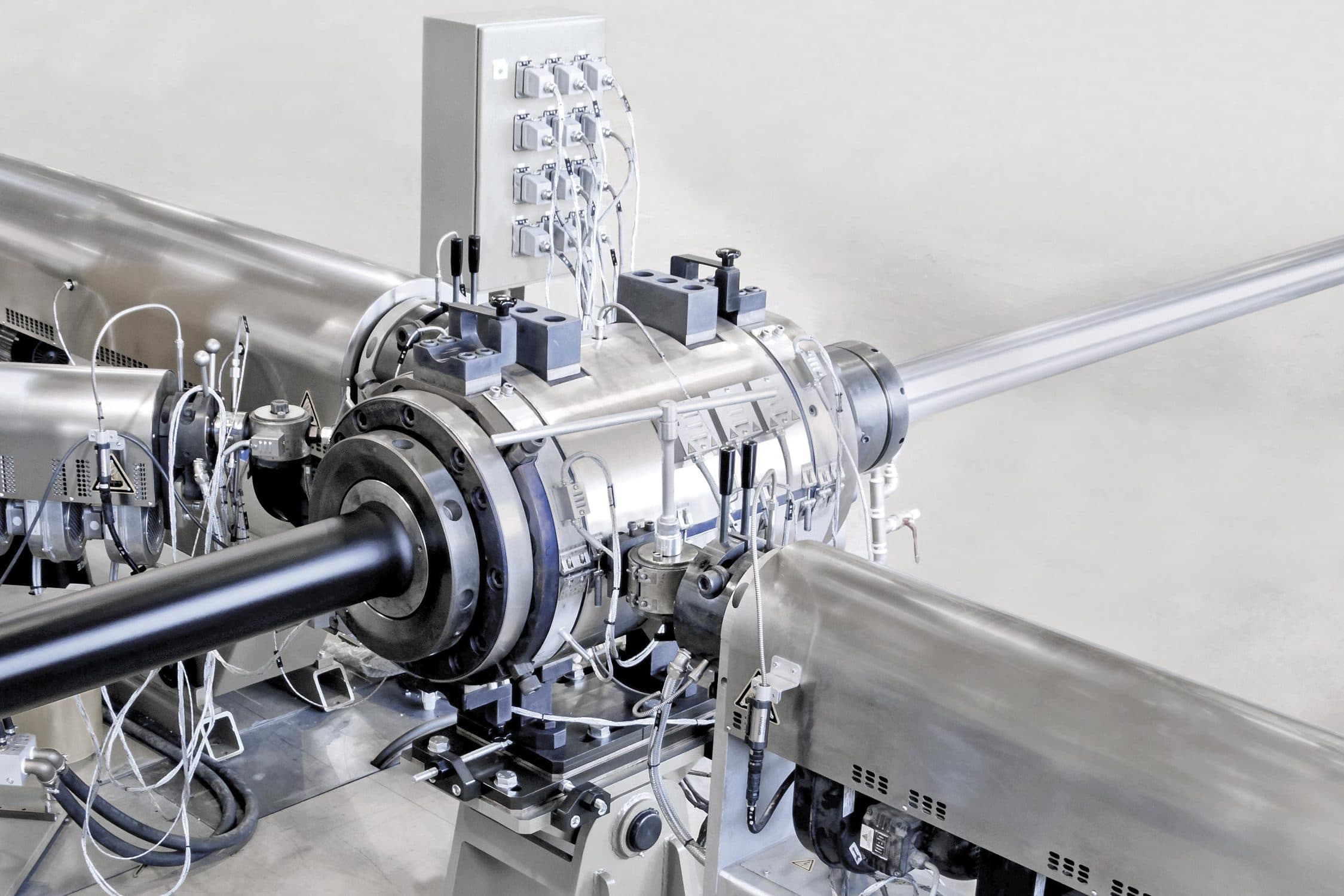

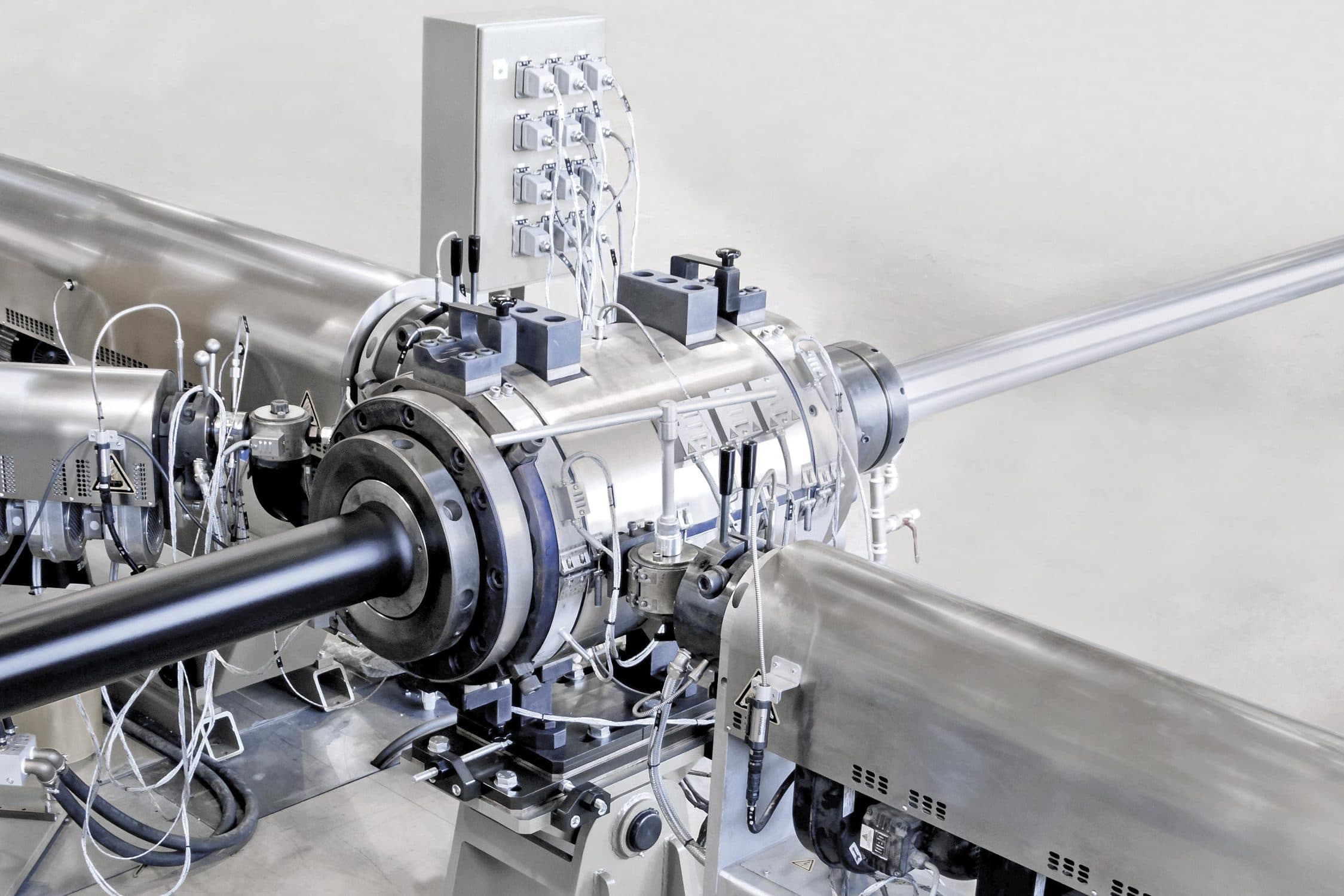

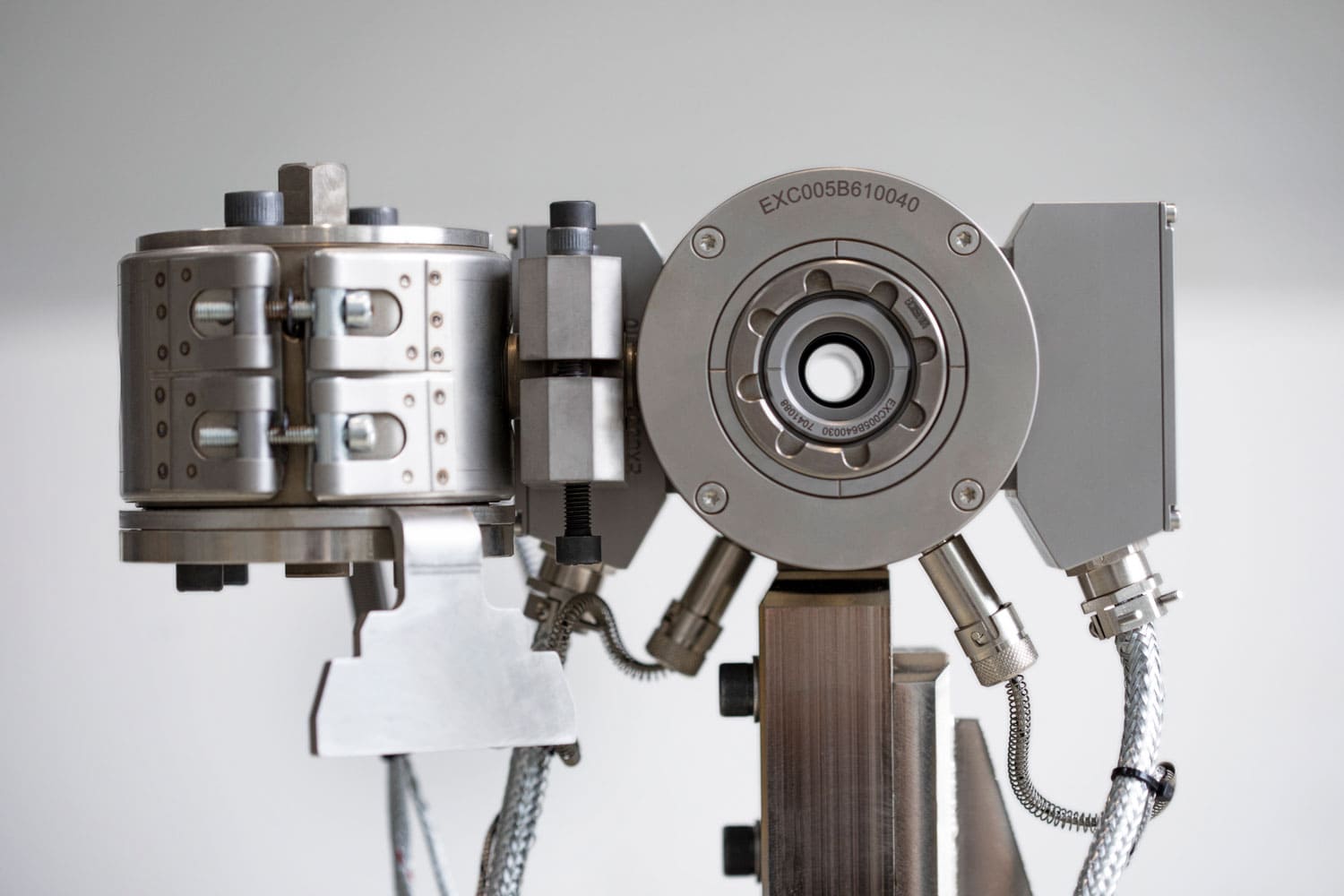

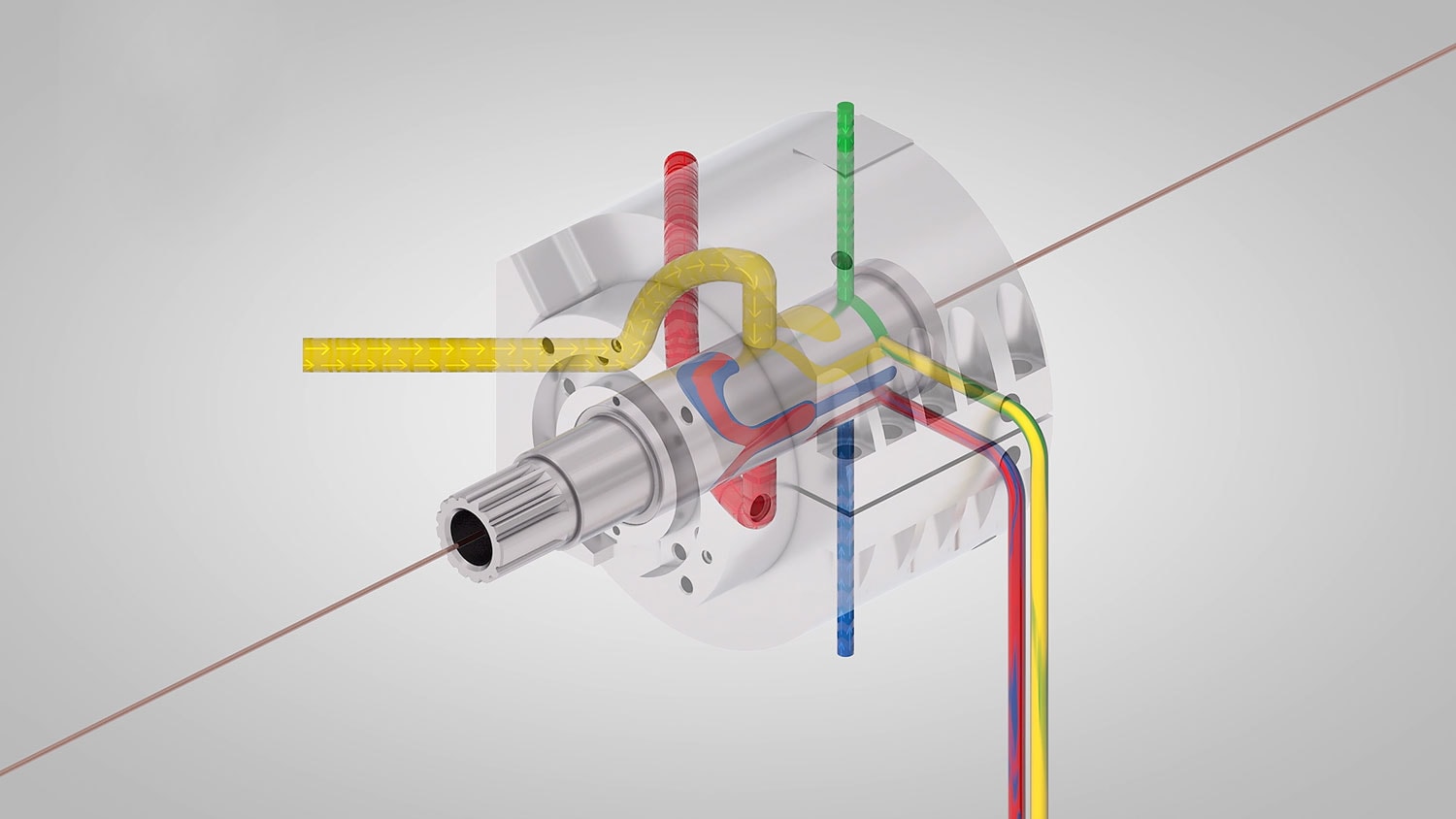

The most common coating variant for LV power cables, the “tandem extrusion”, is increasingly being replaced by so-called “co-extrusion”. On the one hand, because this production process is more efficient and thus more cost-effective, and on the other hand because it is becoming inevitable due to the many different extrusion materials.

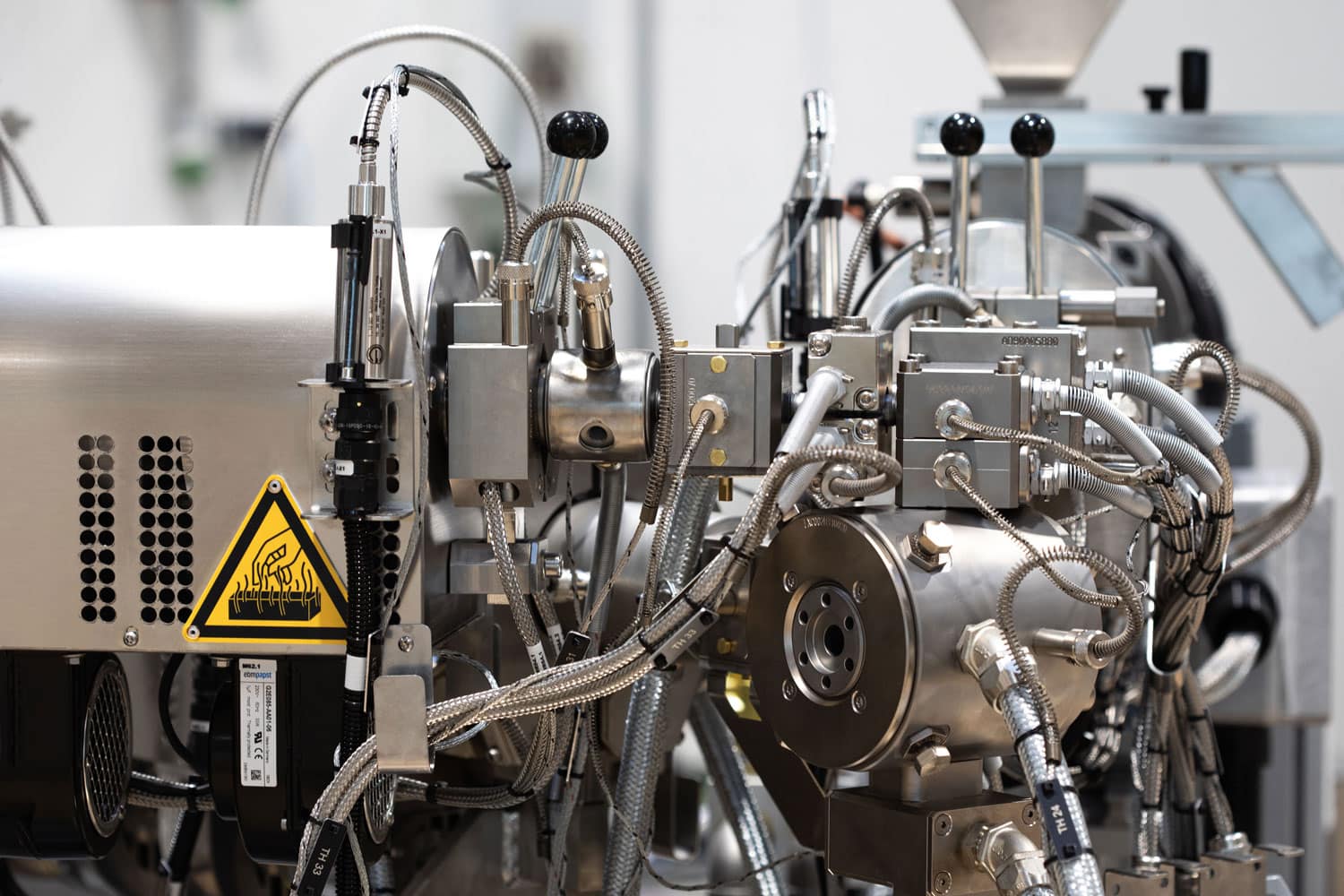

Our new crosshead RX 40 MB 2.1.I was specially developed for these requirements. It enables the co-extrusion of different material combinations, such as EPDM with PVC. And all with only one crosshead!

our top sellers

high quality standards

crossheads that deliver

Perfect product quality

High centricity

RX-type crossheads provide high-precision centricity, thereby preventing over-sized cable wall-thickness and helping saving material and production costs.

Improved crosshead performance

Optimized material distribution by simulation

With the help of simulation software we design an ideal crosshead with perfect material distribution.

Gentle processing with minimum shear

Simulation makes it possible to control a minimum shear rate and a minimum shear stress. This leads to a gentle processing and to a higher lifetime of your crosshead.

Small volume distributor

This leads to short dwell times and quicker color changes, which has a positive effect on set-up times and material costs.

Use of different materials in one crosshead

From HFFR to PA or PUR; this enables a high degree of flexibility in the use of materials, minimizing investment costs.

Modular structure

Operations are simplified by an easy to use, compact, modular design.

Extrusion process stability

Perfectly balanced polymer distribution, temperature- and pressure-profiles guarantee a smooth and stable melt-flow across the outlet zone.

Reduced pressure in the crosshead distributor

This ensures gentle processing of the material, decreases maintenance and spare parts costs.

We teach you the most important things about the extrusion process and about the handling and operating of your equipment.

extrusion crossheads for a wide product range

a fitting crosshead for every application

Power cables

single & multi-layer insulation / jacketing for various materials

Silicone cables

single & multi-layer insulation / jacketing

Automotive cables

single and multi-layer insulation / jacketing, including quick color change

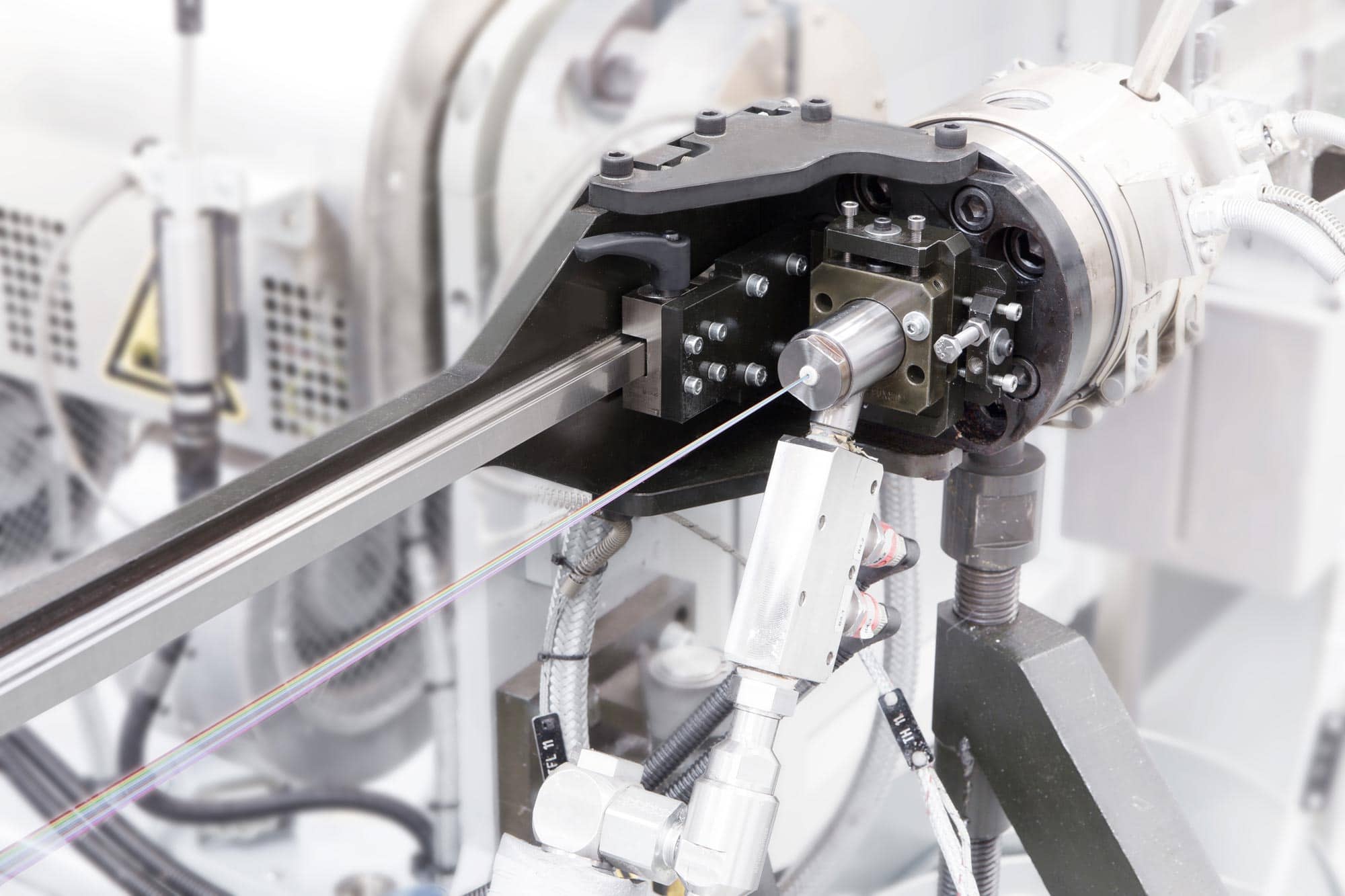

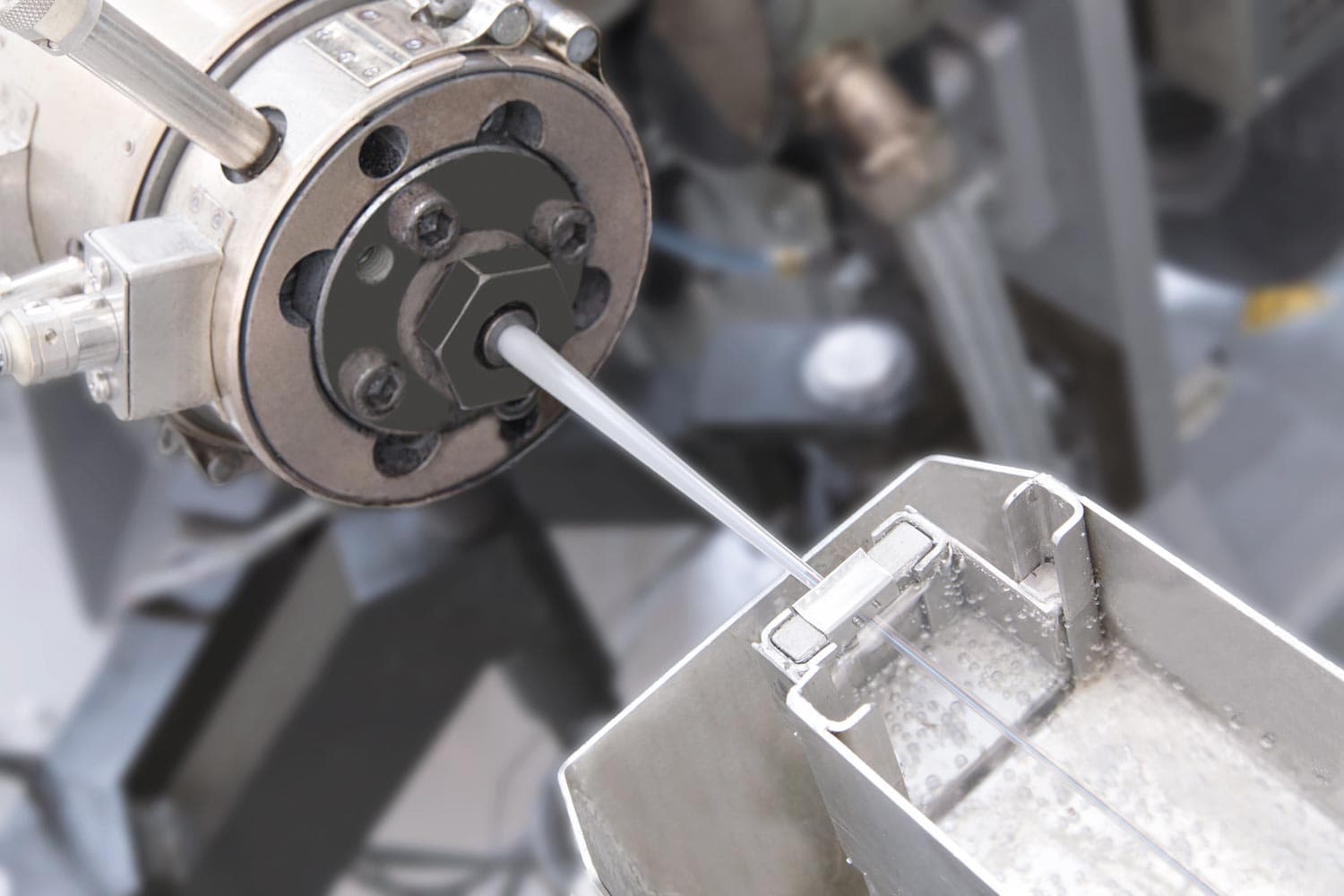

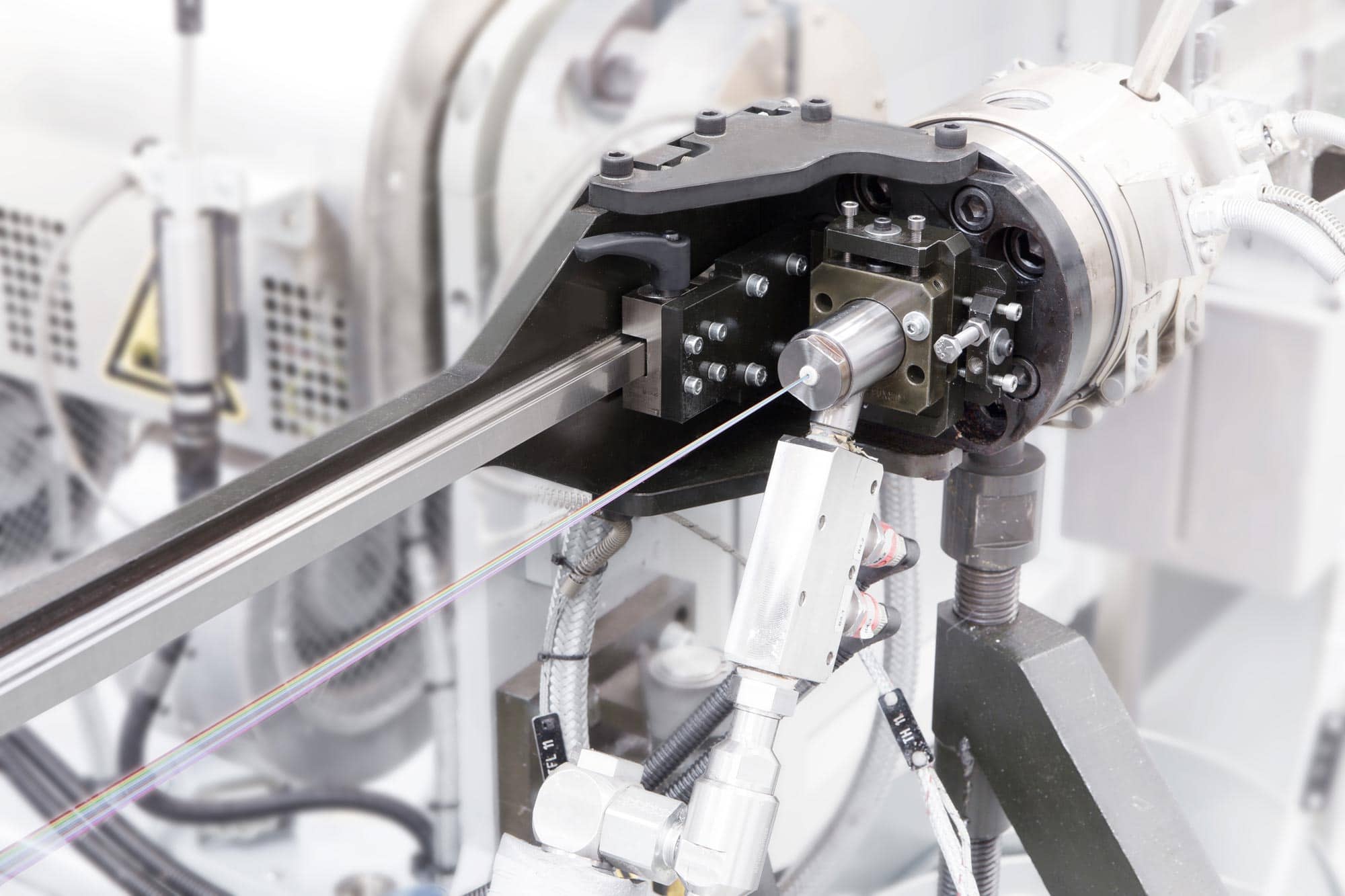

Fiber optic cables

single & multi-layer for tight coating, loose tube & jacketing

LAN cables / coaxial cables

single or multi-layer application for PE, PP & fluoro materials

Steel rope

single & multi-layer insulation / jacketing for various materials

ROCOMAT quick color-change system

From red/blue to yellow/green in 0.3 seconds

With the unique ROCOMAT system, we integrate a color-change function directly into the crosshead. That reduces the color-change volume to an absolute minimum and achieves the shortest color-change length in the industry.

research and development

Optimization never stops

We closely collaborate with universities, institutes, and leading material suppliers. We keep an extensive database for cable material at Rosendahl and we are always up to date with the latest polymer data for:

Standard materials:

- PVC

- PE (LD, MD, HD)

- PP

- PA

- PBT / PC

Special materials:

- Foamed material blends

- Cross-linked polyethylene

- Low-smoke halogen-free material

- Fluoro materials

improved crosshead performance

Optimized material distribution

by simulation

Melt pressure, temperature profile, flow path and friction are the key factors for designing an ideal crosshead with perfect material distribution. By comparing finite element simulation programs with experimental trials, we verify the close correlation between virtually calculated results and laboratory tests. Both elements are then applied to improve crosshead performance and ensure a homogeneous polymer flow for required output.

the RX crosshead series

The Rosendahl Crosshead Series RX includes crossheads for extruding cores with a diameter ranging from 0.03 mm to 180 mm featuring a perfectly balanced distribution of polymers. They are available for processing various kinds of solid and foamed polymer-materials in single- or multi-layer extrusion. All the crossheads are offered as single machines and also in complete lines and fit every kind of extrusion line.

small crosshead diameters

| Specification | RX 2 |

| Minimum core Ø | 0.03 mm |

| Maximum core Ø | 2 mm |

| Minimum die Ø | 0.2 mm |

| Maximum insulation Ø | 3 mm |

| Maximum tube die Ø | 7 mm |

| Maximum pressure | 400 bar |

| Weight | 5.5 kg |

| Layer types | 1.0 single layer 1.1 single layer + skin or stripe 2.0 double layer 2.1 double layer + skin or stripe 3.0 triple layer |

| Application | |

| Field of application | fiber optic, insulation, micro coaxial |

| Materials | fluoro materials, PE, PP, XLPE, TPE, PA, PBT, PC, PVC, PEEK, foamed PE/PP, foamed fluoro materials |

| Special characteristics | |

| Centering types | fixed, fine tuned |

| Number of heating zones | 1 |

| Entry ports | main extruder: Ø 4 mm for single layer, Ø 6 mm for double layer, Ø 4 mm for triple layer auxiliary extruder 1: Ø 4 mm |

| Options | |

| Extruder connections | connection flanges for any type of extruder |

| By-pass | manual |

| Distributors | special distributor design according to polymer |

| Accessories | vacuum adaptor, isolation head operating and cleaning accessories |

| Head support | head stand, head trolley |

| Specification | RX 5 |

| Minimum core Ø | 0.1 mm |

| Maximum core Ø | 5 mm |

| Minimum die Ø | 0.2 mm |

| Maximum insulation Ø | 7 mm |

| Maximum tube die Ø | 12 mm |

| Maximum pressure | 1,000 bar |

| Weight | 18.5 kg |

| Layer types | 1.0 single layer 1.1 single layer + skin or stripe 1.2 Single layer + skin + stripe or single layer + 2 different stripes 2.0 double layer 2.1 double layer + skin or stripe 2.2 double layer + skin + stripe or double layer + 2 different stripes |

| Application | |

| Field of application | coaxial, fiber optic, insulation, LAN, micro coaxial, solar |

| Materials | PE (LD, MD, HD), PP, XLPE, TPE, PA, PBT, PC, PVC, EPDM, flame retardant polymers, foamed PE/PP, fluoro materials, foamed fluoro materials |

| Special characteristics | |

| Centering types | fixed, fine tuned, ball centered |

| Heating zones | 2/3 |

| Entry ports | main extruder: Ø 15 mm auxiliary extruder 1: Ø 9mm auxiliary extruder 2: Ø 10mm |

| Options | |

| Extruder connections | connection flanges for any type of extruder |

| By-pass | manual, pneumatic, hydraulic |

| Distributors | design for special polymers |

| Accessories | vacuum adaptor, tool box |

| Head support | head stand, head trolley |

| Specification | RX 12 |

| Minimum core Ø | 0.2 mm |

| Maximum core Ø | 12 mm |

| Minimum die Ø | 0.3 mm |

| Maximum insulation Ø | 16 mm |

| Maximum tube die Ø | 20 mm |

| Maximum pressure | 750 bar |

| Weight | single layer: 30 kg multi layer: 110 kg |

| Layer types | 1.0 single layer 1.1 single layer + skin or stripe 1.2 single layer + skin + stripe or single layer + 2 different stripes 2.0 double layer 2.1 double layer + skin or stripe 2.2 double layer + skin + stripe or double layer + 2 different stripes |

| Application | |

| Field of application | coaxial, fiber optic, insulation, jacketing, solar |

| Materials | PE (LD, MD, HD), PP, XLPE, TPE, PA, PBT, PC, PVC, EPDM, flame retardant polymers, foamed PE/PP, fluoro polymers, silicone |

| Special characteristics | |

| Centering types | fixed, manual, variable |

| Heating zones | 2 (optional for oil temperature control ) |

| Entry ports | main extruder: Ø 15 mm, 20 mm auxiliary extruder: Ø 8 mm, 12 mm, 15 mm |

| Options | |

| Extruder connections | connection flanges for any type of extruder |

| By-pass | manual, pneumatic, hydraulic |

| Distributors | design for special polymers |

| Accessories | vacuum adaptor, tool box |

| Head support | head stand, head trolley |

| Specification | RX 25 |

| Minimum core Ø | 0.3 mm |

| Maximum core Ø | 25 mm |

| Minimum die Ø | 1.5 mm |

| Maximum insulation Ø | 30 mm |

| Maximum tube die Ø | 35 mm |

| Maximum pressure | 500 bar |

| Weight | 50 kg |

| Layer types | 1.0 single layer 1.1 single layer + skin or stripe 1.2 single layer + skin + stripe or single layer + 2 different stripes 2.0 double layer 2.1 double layer + skin or stripe 2.2 double layer + skin + stripe double layer + 2 different stripes 3.0 triple layer |

| Application | |

| Field of application | coaxial, insulation, medium voltage, jacketing, solar |

| Materials | PE (LD, MD, HD), PP, XLPE, TPE, PA, PVC, EPDM, flame retardant polymers, foamed PE/PP, fluoro polymer |

| Special characteristics | |

| Centering types | fixed, manual, variable, ball centered |

| Heating zones | 2*/3 (*optional for oil temperature control) |

| Entry ports | main extruder: Ø 25 mm auxiliary extruder: Ø 12 mm |

| Options | |

| Extruder connections | connection flanges for any type of extruder |

| By-pass | manual, pneumatic, hydraulic |

| Distributors | design for special polymers |

| Accessories | vacuum adaptor, tool box |

| Head support | head stand, head trolley |

medium crosshead diameters

| Specification | RX 35 |

| Minimum core Ø | 1.5 mm |

| Maximum core Ø | 35 mm |

| Minimum die Ø | 2.5 mm |

| Maximum insulation Ø | 40 mm |

| Maximum tube die Ø | 45 mm |

| Maximum pressure | 500 bar |

| Weight | 50 kg |

| Layer types | 1.0 single layer 1.1 single layer + skin or stripe 1.2 single layer + skin + stripe or single layer + 2 different stripes |

| Application | |

| Field of application | silicone, coaxial, insulation, jacketing |

| Materials | PE (LD, MD, HD), PP, XLPE, TPE, PA, PVC, EPDM, flame retardant polymers, foamed PE/PP, silicone |

| Special characteristics | |

| Centering types | fixed, manual, variable |

| Heating zones | 2/3 |

| Entry ports | main extruder: Ø 25 mm auxiliary extruder: Ø 12 mm |

| Options | |

| Extruder connections | connection flanges for any type of extruder |

| By-pass | manual, pneumatic, hydraulic |

| Distributors | design for special polymers |

| Accessories | vacuum adaptor, tool box |

| Head support | head stand, head trolley |

| Specification | RX 40 |

| Minimum core Ø | 3 mm |

| Maximum core Ø | 40 mm |

| Minimum die Ø | 3.5 mm |

| Maximum insulation Ø | 45 mm |

| Maximum tube die Ø | 50 mm |

| Maximum pressure | 500 bar |

| Weight | 90 kg |

| Layer types | 1.0 single layer 1.1 single layer + skin or stripe 1.2 single layer + skin + stripe or single layer + 2 different stripes 2.0 double layer 2.1 double layer + skin or stripe 2.2 double layer + skin + stripe double layer + 2 different stripes |

| Application | |

| Field of application | insulation, jacketing, solar |

| Materials | PE (LD, MD, HD), PP, TPE, PA, PVC, EPDM, flame retardant polymers, fluoro polymers |

| Special characteristics | |

| Centering types | fixed, manual, variable |

| Heating zones | 2/3 |

| Entry ports | main extruder: Ø 35 mm auxiliary extruder: Ø 15 mm |

| Options | |

| Extruder connections | connection flanges for any type of extruder |

| By-pass | manual, pneumatic, hydraulic |

| Distributors | design for special polymers |

| Accessories | vacuum adaptor, tool box |

| Head support | head stand, head trolley |

| Specification | RX 45 |

| Minimum core Ø | 3 mm |

| Maximum core Ø | 45 mm |

| Minimum die Ø | 6 mm |

| Maximum insulation Ø | 60 mm |

| Maximum intermediate die Ø | 55 mm |

| Maximum pressure | 500 bar |

| Weight | 600 kg |

| Layer types | 3.0 triple layer |

| Application | |

| Field of application | insulation of MV cables |

| Materials | XLPE, semicon |

| Special characteristics | |

| Centering types | manual |

| Heating zones | 3 |

| Entry ports | main extruder: Ø 30 mm auxiliary extruders: Ø 20 mm |

| Options | |

| Extruder connections | connection flanges for any type of extruder |

| Distributors | design for special polymers |

| Head support | head stand, head trolley |

| Specification | RX 60 |

| Minimum core Ø | 4 mm |

| Maximum core Ø | 60 mm |

| Minimum die Ø | 4.2 mm |

| Maximum insulation Ø | 70 mm |

| Maximum tube die Ø | 75 mm |

| Maximum pressure | 400 bar |

| Weight | 145 kg |

| Layer types | 1.0 single layer 1.1 single layer + skin or stripe 1.2 single layer + skin + stripe or single layer + 2 different stripes |

| Application | |

| Field of application | insulation, jacketing |

| Materials | PE (LD, MD, HD), PP, TPE, PA, PVC, EPDM, flame retardant polymers |

| Special characteristics | |

| Centering types | fixed, manual, variable |

| Heating zones | 2/3 |

| Entry ports | main extruder: Ø 40 mm auxiliary extruder: Ø 15 mm |

| Options | |

| Extruder connections | connection flanges for any type of extruder |

| By-pass | manual, pneumatic, hydraulic |

| Distributors | special distributor design according to polymer |

| Accessories | vacuum adaptor, head operating and cleaning accessories |

| Head support | head stand, head trolley |

| Specification | RX 80 |

| Minimum core Ø | 5.5 mm |

| Maximum core Ø | 80 mm |

| Minimum die Ø | 5.7 mm |

| Maximum insulation Ø | 95 mm |

| Maximum tube die Ø | 110 mm |

| Maximum pressure | 400 bar |

| Weight | 280 kg |

| Layer types | 1.0 single layer 1.1 single layer + skin or stripe 1.2 single layer + skin + stripe or single layer + 2 different stripes |

| Application | |

| Field of application | insulation, jacketing |

| Materials | PE (LD, MD, HD), PP, TPE, PA, PVC, EPDM, flame retardant polymers |

| Special characteristics | |

| Centering types | fixed, manual, variable |

| Heating zones | 2/3 |

| Entry ports | main extruder: Ø 40 mm auxiliary extruder: Ø 15 mm |

| Options | |

| Extruder connections | connection flanges for any type of extruder |

| By-pass | manual, pneumatic, hydraulic |

| Distributors | special distributor design according to polymer |

| Accessories | vacuum adaptor, head operating and cleaning accessories |

| Head support | head stand, head trolley |

big crosshead diameters

| Specification | RX 110 |

| Minimum core Ø | 7.5 mm |

| Maximum core Ø | 110 mm |

| Minimum die Ø | 7.7 mm |

| Maximum insulation Ø | 125 mm |

| Maximum tube die Ø | 130 mm |

| Maximum pressure | 400 bar |

| Weight | 275 kg |

| Layer types | 1.0 single layer 1.1 single layer + skin or stripe 1.2 single layer + skin + stripe or single layer + 2 different stripes |

| Application | |

| Field of application | insulation, jacketing |

| Materials | PE (LD, MD, HD), PP, PA, PVC, EPDM, TPE, flame retardant polymers |

| Special characteristics | |

| Centering types | fixed, manual, variable |

| Heating zones | 2/3 |

| Entry ports | main extruder: Ø 45 mm auxiliary extruder: Ø 15 mm |

| Options | |

| Extruder connections | connection flanges for any type of extruder |

| By-pass | manual, pneumatic, hydraulic |

| Distributors | special distributor design according to polymer |

| Accessories | vacuum adaptor, head operating and cleaning accessories |

| Head support | head stand, head trolley |

| Specification | RX 150 |

| Minimum core Ø | 15 mm |

| Maximum core Ø | 150 mm |

| Minimum die Ø | 17 mm |

| Maximum insulation Ø | 165 mm |

| Maximum tube die Ø | 180 mm |

| Maximum pressure | 400 bar |

| Weight | 1,130 kg |

| Layer types | 1.0 single layer 1.1 single layer + skin or stripe 1.1.S single layer + skin or stripe with inner skin for adhesion layer available 1.2 single layer + skin + stripe or single layer + 2 different stripes |

| Application | |

| Field of application | insulation, jacketing |

| Materials | PE (LD, MD, HD), PP, PA, PVC, EPDM, flame retardant polymers |

| Special characteristics | |

| Centering types | manual |

| Heating zones | 3/4 |

| Entry ports | main extruder: Ø 45 mm auxiliary extruder: Ø 20 mm |

| Options | |

| Extruder connections | connection flanges for any type of extruder |

| By-pass | manual, pneumatic, hydraulic |

| Distributors | special distributor design according to polymer |

| Accessories | vacuum adaptor, head operating and cleaning accessories, service station including storage table |

| Head support | head stand, head trolley |

| Specification | RX 180 |

| Minimum core Ø | 25 mm |

| Maximum core Ø | 180 mm |

| Minimum die Ø | 25 mm |

| Maximum insulation Ø | 195 mm |

| Maximum tube die Ø | 240 mm |

| Maximum pressure | 250 bar |

| Weight | 1,570 kg |

| Layer types | 1.0 single layer 1.1 single layer + skin or stripe 1.1.S single layer + skin or stripe with inner skin for adhesion layer available 1.2 single layer + skin + stripe or single layer + 2 different stripes |

| Application | |

| Field of application | insulation, jacketing |

| Materials | PE (LD, MD, HD), PP, PA, PVC, EPDM, flame retardant polymers |

| Special characteristics | |

| Centering types | manual |

| Heating zones | 2/3 |

| Entry ports | main extruder: Ø 45 mm auxiliary extruder: Ø 25 mm |

| Options | |

| Extruder connections | connection flanges for any type of extruder |

| By-pass | manual, pneumatic, hydraulic |

| Distributors | special distributor design according to polymer |

| Accessories | vacuum adaptor, head operating and cleaning accessories, service station including storage table |

| Head support | head stand, head trolley |

What are your crosshead requirements?

Fill in our crosshead request form and send it to the contact on the last page.

RX accessories

Tool sets: tips & dies

For original RX crossheads

Bypass systems

Manual / pneumatic / hydraulic drive, or pressure-controlled

Support / trolleys

Available for small and big crossheads

Original spare parts for crossheads on stock

We keep a well-sorted spare part stock at our site.

contact

get in

touch

with us

If you need further information on our crosshead product range or if you are interested in a tailor-made solution, don’t hesitate to contact us.