excellent

cables for

extreme conditions

Premium extrusion equipment

and intensive process know-how for fluorine and high-performance plastics

premium machinery for special cable production

enabling outstanding cable performance in special applications

There are fields in which cable products must deliver exceptional performance. Where even greater precision is required, where exclusive materials are used, and where conventional solutions reach their limits.

When it comes to the production of special cables with special properties, such as high chemical and mechanical stability, the desired machine performance rises to a high level. You are looking for a supplier that understands your requirements?

Extrusion solutions for exceptional performance

Twinax cables

Helping supercomputers think faster

Data transmission rates of terabytes per second with extremely low latency require absolute precision in all stages of cable manufacturing. Leading cable producers worldwide rely on our hightemperature foam lines for insulation, setting the international standard for cable performance in AI data centers.

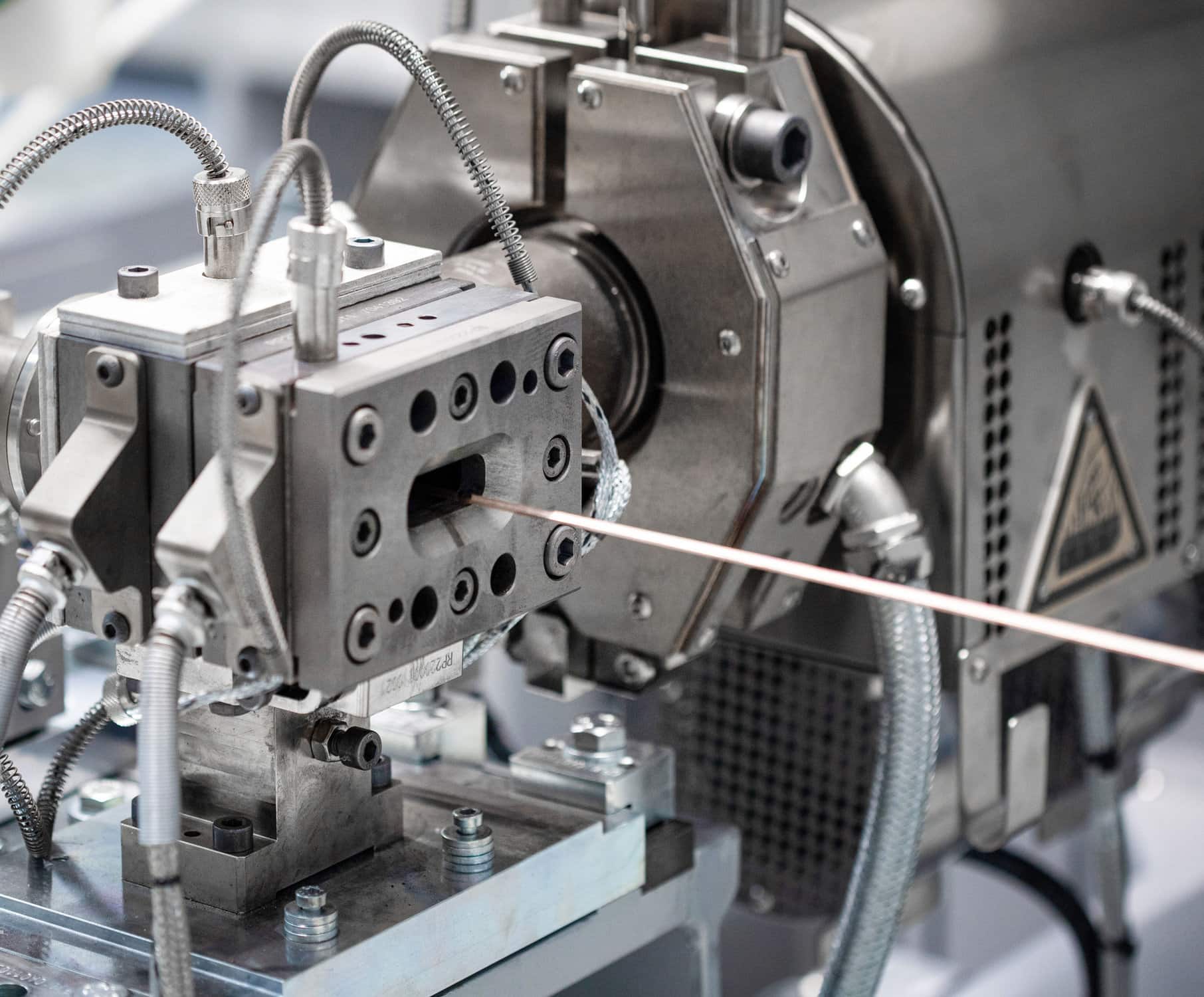

Micro-coaxial cables

Processing wires thinner than a human hair

With our special wire extrusion equipment, you can process micro-coaxial cables as small as 0.025 mm in diameter. A product with these properties is mainly used for high-end applications, e.g., in medical technology, or aerospace.

High flexibility with modular line concept

Manufacture a variety of communication cable designs for special use on one line

Lowest scrap for expensive materials

Save costs thanks to short start-up time and constant production processes

Excellent quality parameters

Produce cable with superior chemical, mechanical, and dielectric properties

profit from decades of experience

We can handle high-performance materials

High-temperature materials (FEP, PFA, ETFE, PEEK, TPI) cannot be processed in the same way as standard materials. Precise calculations and tool designs are necessary to prevent damage and achieve an optimum result. That requires a great deal of expertise and experience that we have been able to acquire over many decades. We are constantly researching new material compositions and refining our processes.

In addition, we maintain close relationships with suppliers of specialty materials. That gives us valuable insights into the market and first-hand knowledge of demand and parameters.

Peter Windhaber

your specialist for manufacturing solutions for special cables

heat and fire resistant cables

When temperatures rise,

so do requirements

Can you imagine a cable that can withstand temperatures of up to 250 °C for several minutes? To meet this or similar requirements, every production step must be precisely coordinated.

Very small deviations are enough to change the properties of the materials used. Therefore, precise control of temperature and optimized equipment are key to an excellent final product. The core components – crosshead and extruder – have to withstand temperatures of up to 450 degrees.

Premium machinery for special cable production

Rosendahl process know-how for your success

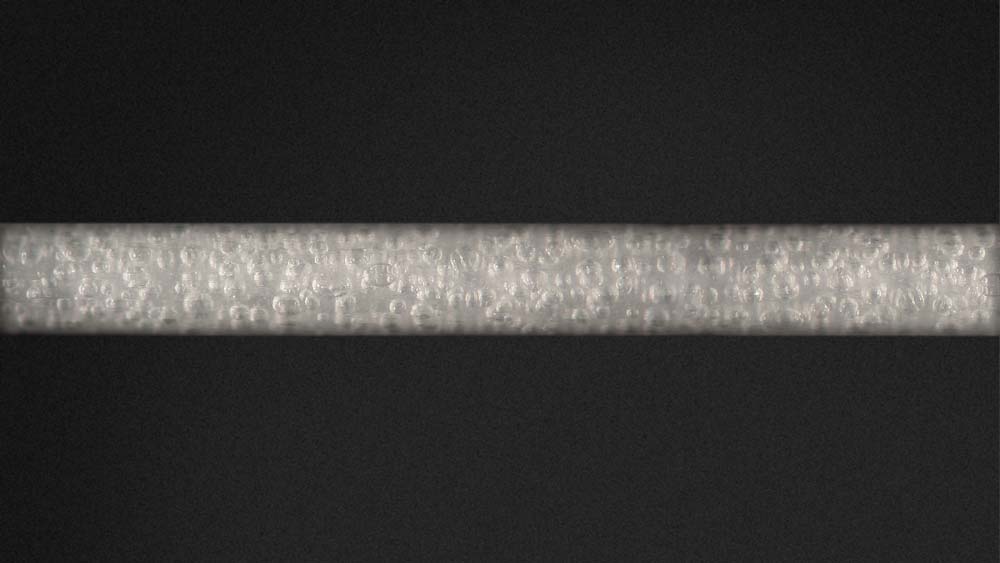

Get fine and uniform foam structure – repeatedly

Foaming of high-end products with sensitive materials is one of our core competencies. The Rosendahl extrusion technology in combination with our high-pressure precision gas-dosing system ensures long-term process stability and a very fine and uniform foam structure.

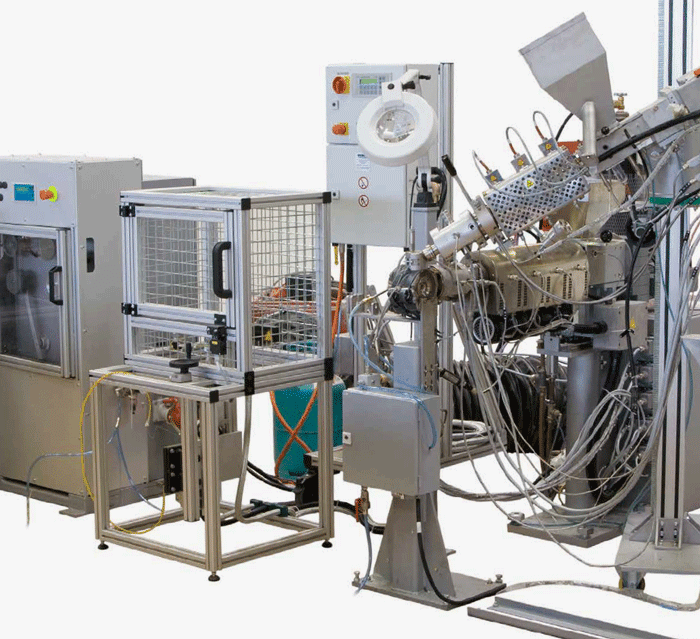

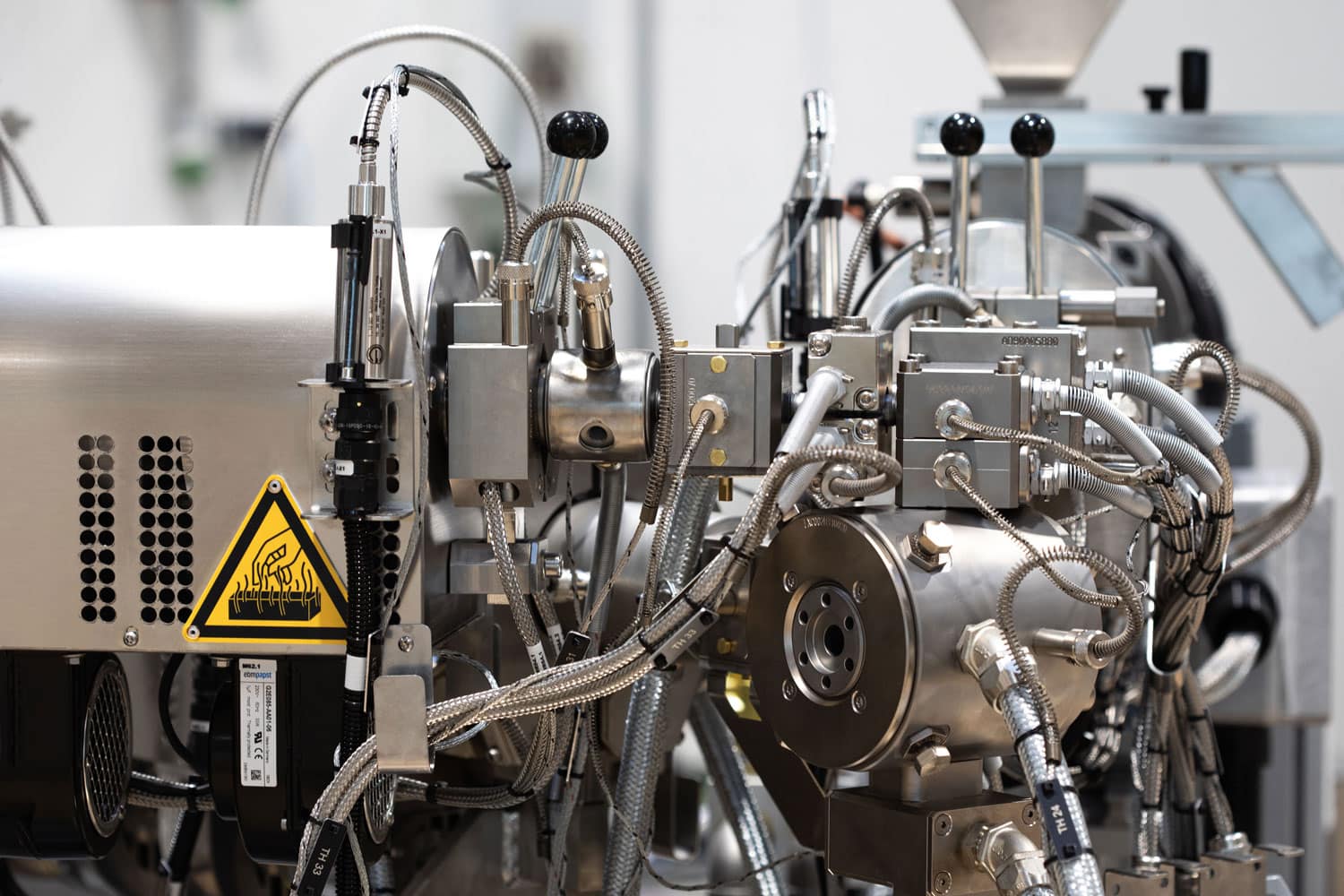

Well-matched equipment for high performance

It takes all the line components, from pay-off, extruder, crosshead, double reeler, and take-up, to support the utmost product quality.

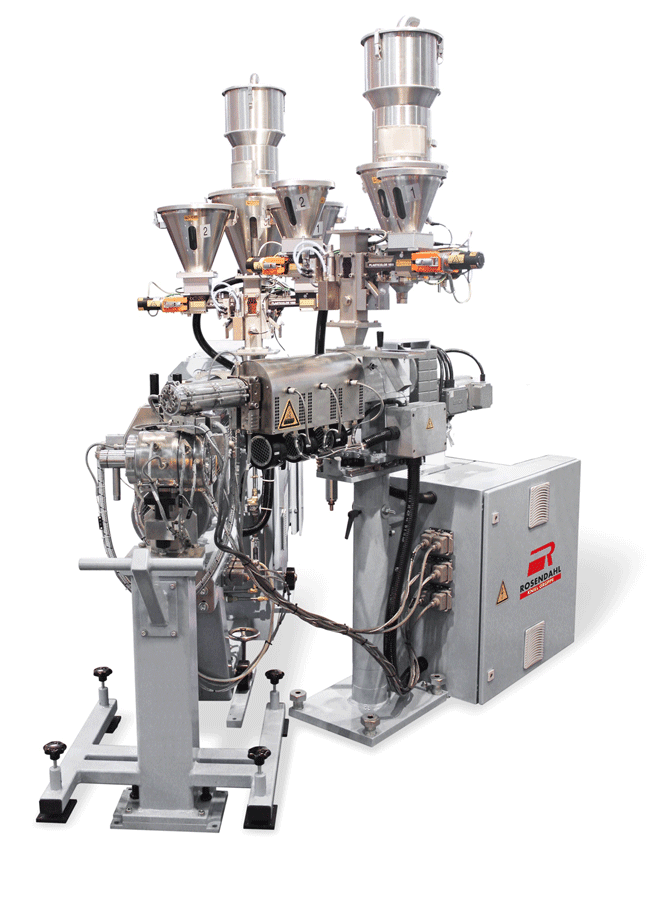

Extruder and screw design

Achieve outstanding product quality due to low shear of sensitive materials.

High-temperature or fluorine-proof extruders for processing FEP, PFA, ETFE, PEEK, and TPI.

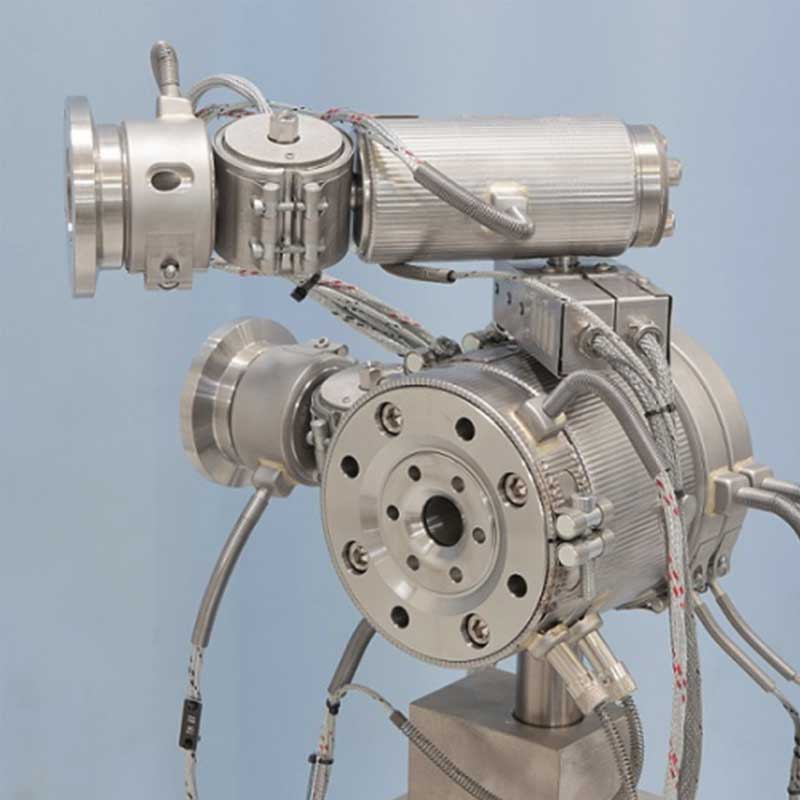

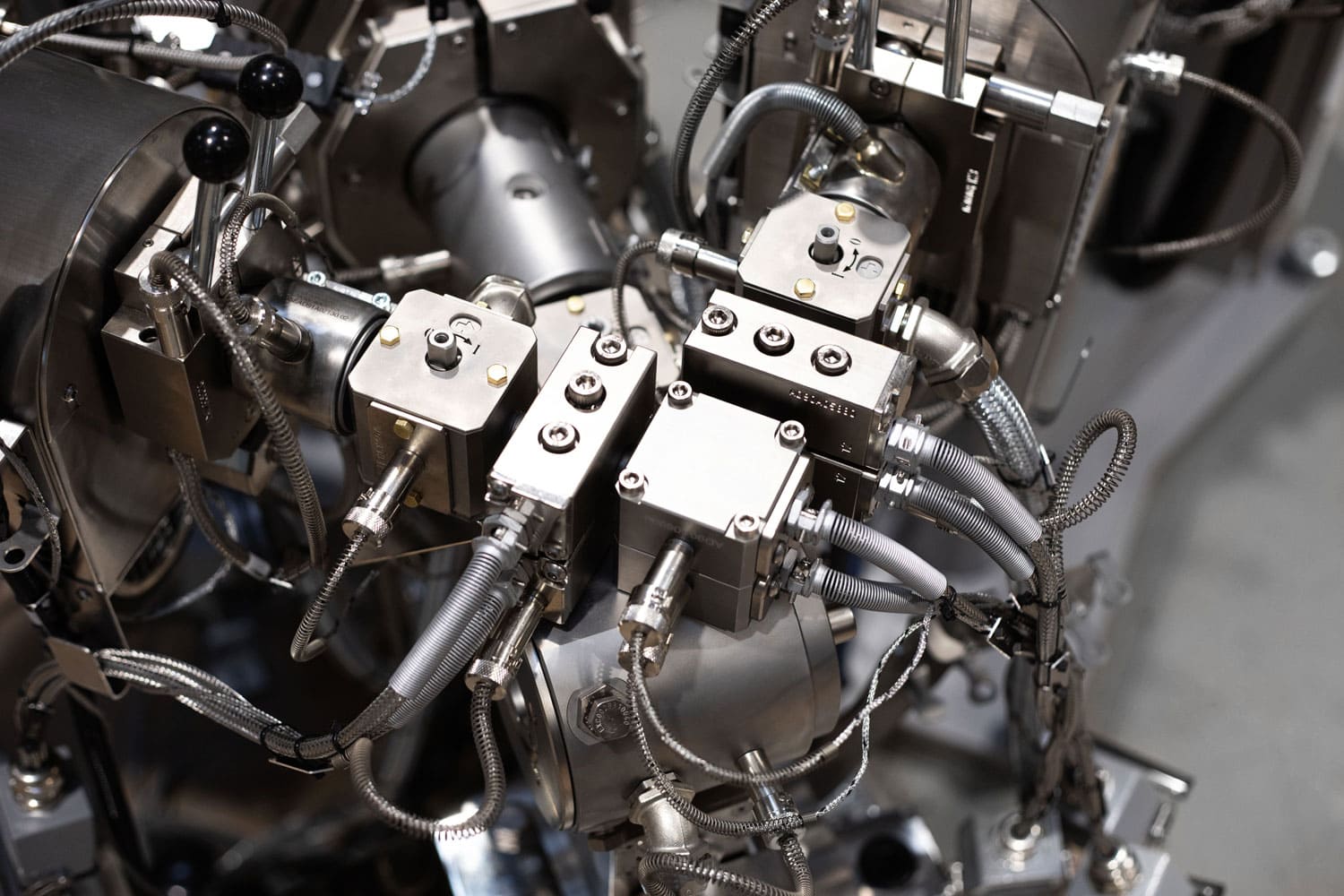

Crosshead design

Expect perfect material flow for perfect centricity.

Minimum residence time maintains the material’s properties and supports smooth production.

Powerful line control

Monitor and optimize your production process with specially designed tools within our RIO line control system.

machinery for the production of special cables

get to know our production lines for special cable performance

technical data

RD-I Extrusion line for special materials

The RD-I insulation line is our solution for solid and foamed LAN cable or mini-micro-coaxial cable production. It creates an excellent foaming structure for high quality special cable production. Our dedicated line configuration insulates copper, copper alloy and plated copper conductors.

-

Diameter over insulation 0.40 – 5.00 mm

0.08 – 1.5 mm -

Line speed up to 1,000 m/min

-

Insulation materials solid and foamed FEP, PFA and ETFE

-

Foaming Degree Fluoropolymere max. 50 %

technical data

RN-I Extrusion line for special materials

The RN-I insulation line is our solution for solid cable production with high temperature materials like PEEK, PSU, TPI and all extrudable Fluoropolymers. Our line configuration is designed for insulation or sheathing applications.

-

Diameter over insulation 0.20 – 25.00 mm

-

Line speed up to 500 m/min

-

Insulation materials FEP, PFA, ETFE, MFA, PFA, PEEK PSU, and TPI

brand-new

RA-I Extrusion line for hairpin insulation

From pay-off to take-up, every line component of the RA-I extrusion line has been carefully synchronized to meet the high demands of the rectangular hairpin wire.

extrusion equipment for a wide product range

Product segments covered by our high-temperature extrusion lines

Micro-Coaxial

with solid or foamed insulation

AWG 50 – AWG 30

LAN (PE, PP and fluoropolymers)

CAT5, CAT6, CAT7, and higher

with solid and foamed insulation

Special Products

with solid insulation of all extrudable high-temperature materials

Tailor-made in Europe

specially designed according to your individual requirements

contact

get in

touch

with us

You are looking for a supplier that understands your requirements? Thanks to our many years of process experience with fluorine and high-performance plastics, we can provide valuable support regarding any process-related questions and prospects. That way, you’ll receive your personal and customized production line that does exactly what you expect.