shock tube quality makes the difference

Fast and secure shock tube production machinery with minimum scrap rates

high-end shock tube manufacturing solution

Controlled and targeted detonation requires expertise and high-quality tools and equipment.

The explosives industry encompasses many areas. Be it surface blasting, mine blasting, or blasting in tunnel construction, road construction or building disposal; shock tubes for non-electric detonators produced on our machinery always deliver.

extrusion

is what we do best

Profit from decades of intense process know-how in extrusion technology. Whatever your requirements are, we will provide you with a production line that will convince you in terms of both quality and output.

Get enhanced quality with our three-layer design

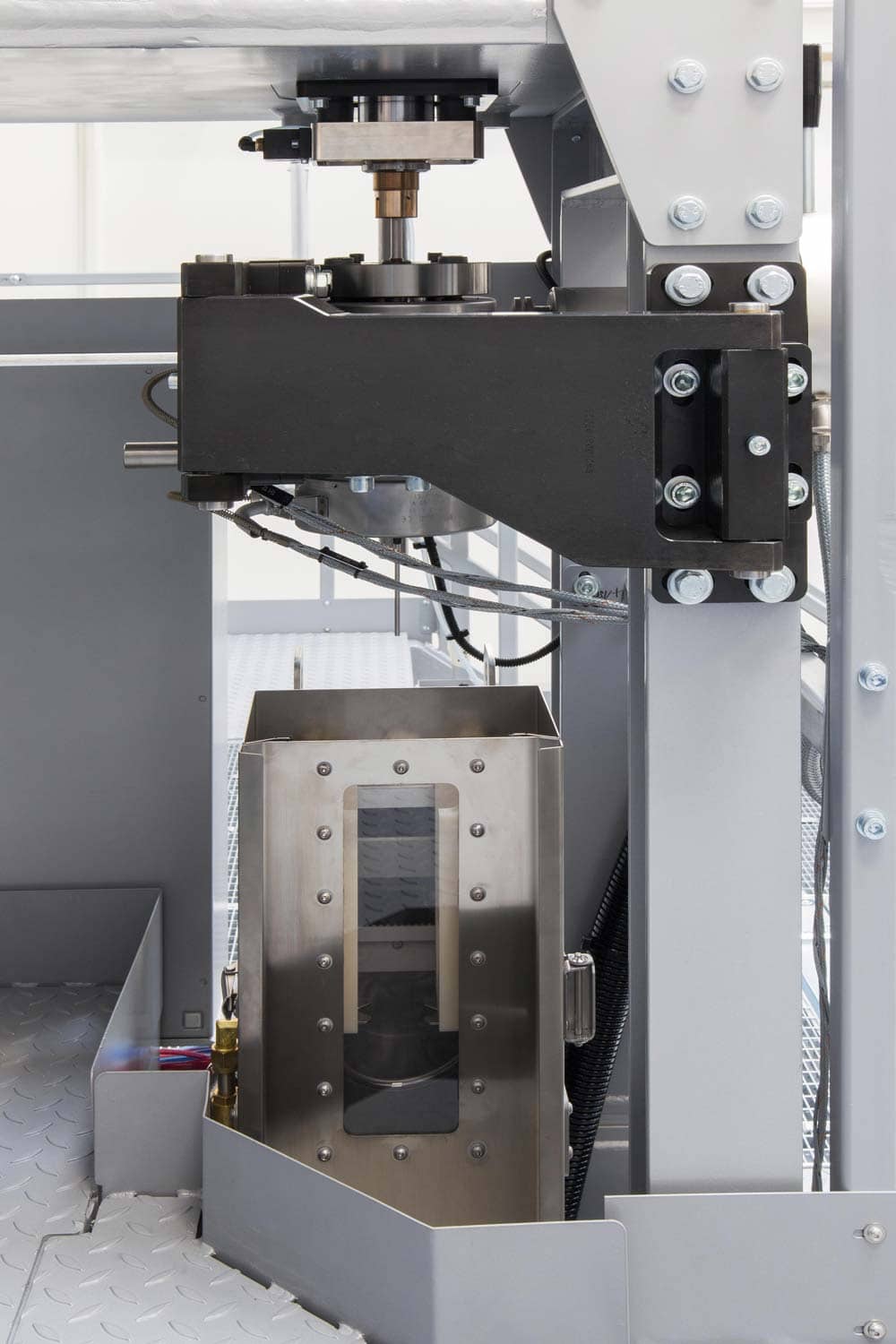

In our line configuration, the vertical extrusion of the inner tube is performed with one extruder and a crosshead. The second and third tube layers are applied using a crosshead and 2 extruders in co-extrusion. That leads to enhanced quality and resistance compared to conventional two-layered products.

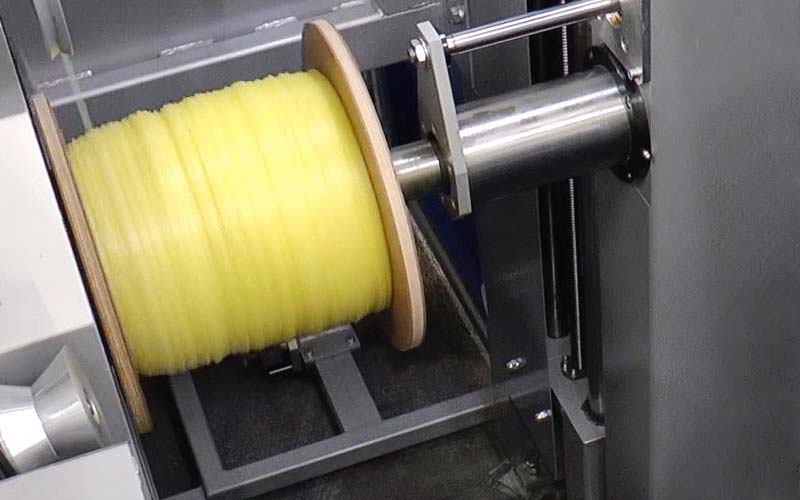

Produce 400m of perfect shock tube per minute

Yes, our line runs fast. It reaches a constant production speed of up to 400m/min. That will take your production capacity to a new level.

Get the lowest scrap rate on the market

There’s no use in producing scrap. It’s a waste of time, money, and resources. At less than 1 %, our average scrap rate during continuous production is significantly lower than industry standards.

yes, quality matters!

Produce unrivalled shock tube quality

You want your shock tube to ignite when it is supposed to. Not beforehand and not afterwards. When you lay kilometers of tubes, you need to be able to rely on every centimeter.

Gerhard Hofer

your specialist for shock tube production lines

Even powder distribution

With the help of a special sensor, the even dosing and distribution of the HMX powder inside the shock tube is continuously monitored online.

As soon as deviations occur, you will be notified.

Perfect shock tube diameter

A precise diameter control system guarantees constant wall thickness. This reliably prevents lumps and neckdowns, and lets you connect your igniter easily.

High physical and mechanical resistance

Shock tubes must withstand all kinds of mechanical stress and weather conditions for months. Our 3-layer structure enables a tensile strength of up to 250 newtons.

Utmost safety for your operators

The safety of your operators has utmost priority. The shock tube line won’t start as long as someone is on the platform. The following security features will help make sure your operators only have to intervene as little as possible and are safe throughout the whole production process.

- Smart locking mechanism for secure start-up

- Pyrotechnically initiated safety cutter with a response time of 2 ms

- Fully automated HMX feeding

- Double tube winder with automatic reel change

- Antistatic charge prevention

- Tube cooling system

- Continuously monitored HMX dosing

- Smart alarm management

smart solutions for your production process

Constant quality and safety monitoring with RIO line control

Our integrated line control system keeps an eye on your whole production process. Deviations during operation are detected immediately. That ensures safe production with high quality standards.

RC-I Extrusion Line

Designed for producing shock tubes for non-electric detonators for the explosives industry.

-

Shock tube Three-layer tube with HMX powder filling

-

Inner diameter 1.2 mm

-

Outer diameter 3.0 mm

-

Line speed 400 m/min

Tailor-made in Europe

Specially designed to meet your individual requirements

contact

get in

touch

with us

You want to know more about the security features of our shock tube line? You have questions regarding quality?

If there’s anything else you’d like to know about our equipment for shock tube production, drop us a line, we’ll be happy to help!