what fibers

can count on

Rosendahl Nextrom –

Tailor-made equipment for

fiber optical cable production.

our machines deliver

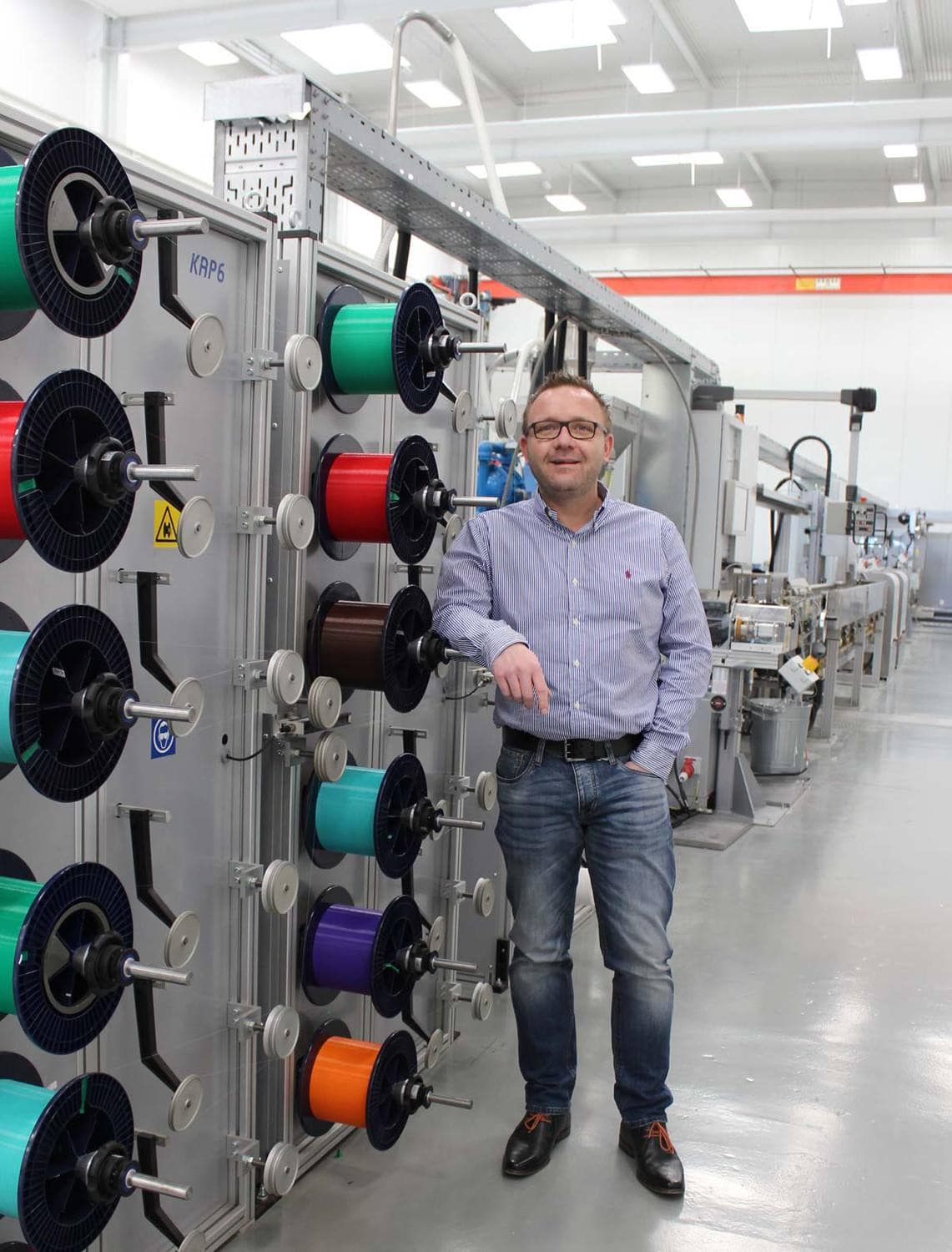

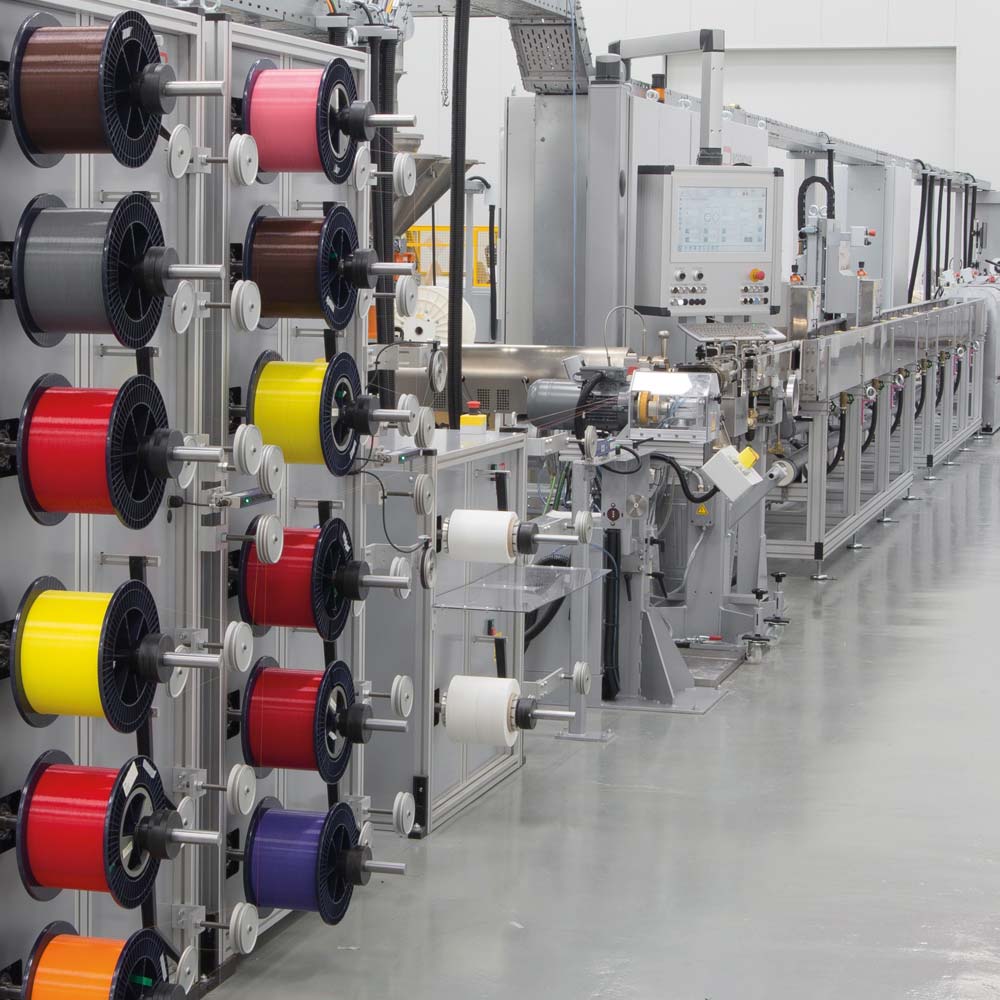

Increasing data capacities in optical signal transmission require ever-smaller cable diameters and higher fiber density at the same time. With Rosendahl machinery, you are well equipped to meet the requirements of tomorrow with a lot more benefits on top.

We offer complete fiber optic cable (FOC) manufacturing solutions, from fiber to finished cable, as well as individual solutions for the individual process steps of fiber optical cable production.

perfectly processed and protected

Flexible machinery for many different product designs

Outdoor

fiber optical cables

Produce robust cables with high fiber counts and transmission rates for outdoor use

Indoor

fiber optical cables

Produce flexible and reliable cables for indoor installations with short distances

Minimize your scrap rates

With the help of precisely adjusted machines and smart software solutions

Speed up

your process

Increase your output with fast and smoothly running machinery

Don’t compromise on quality

Profit from our process know-how to manufacture flawless end products

Tailor-made in Europe

Customized to your individual requirements

fine-tuned technology for sensitive products

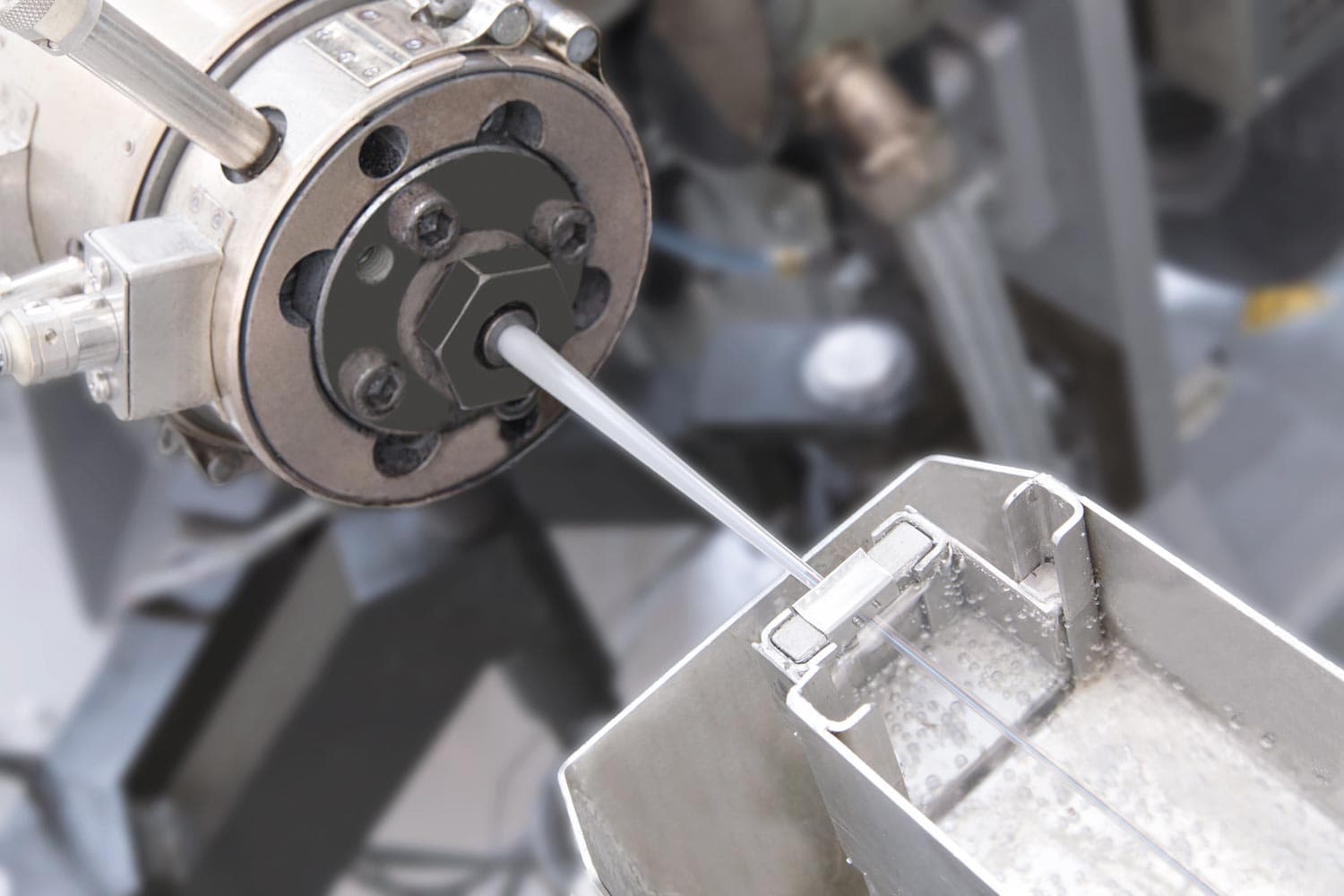

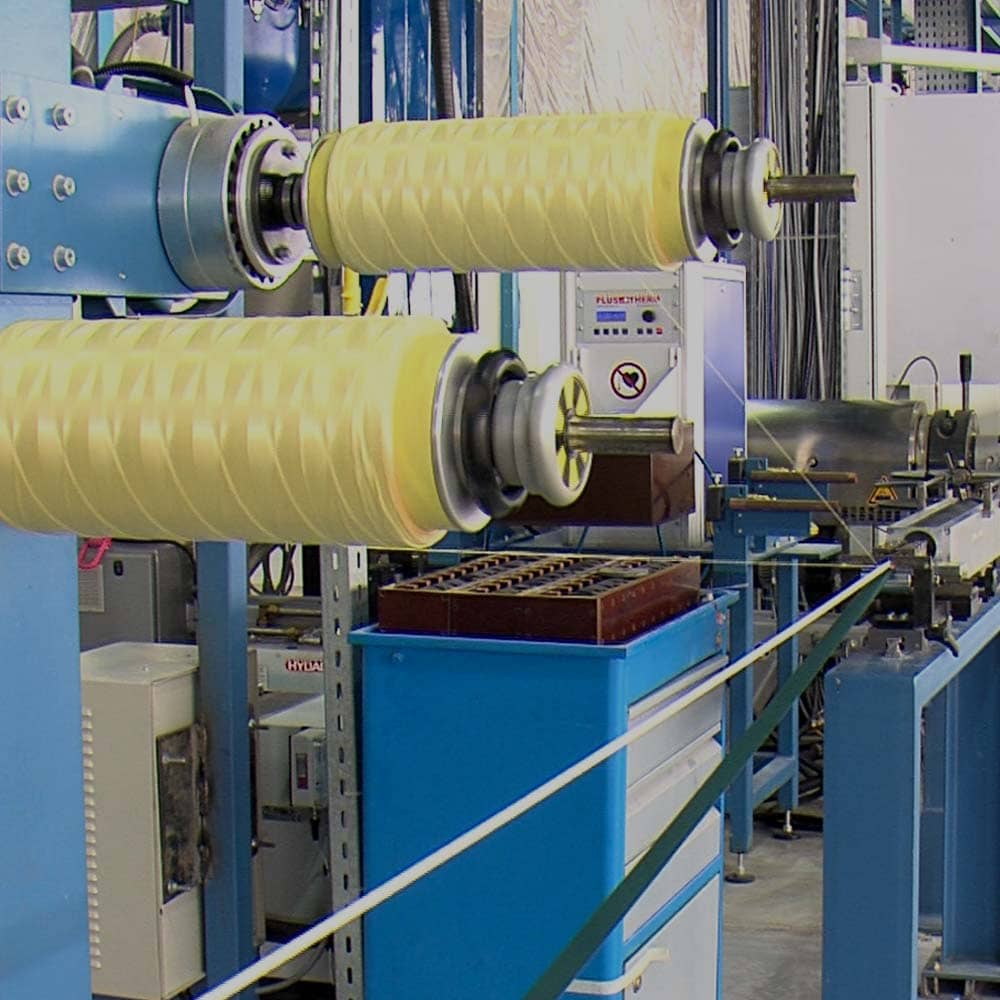

High-speed production of microtubes

with up to 1,200 m/min

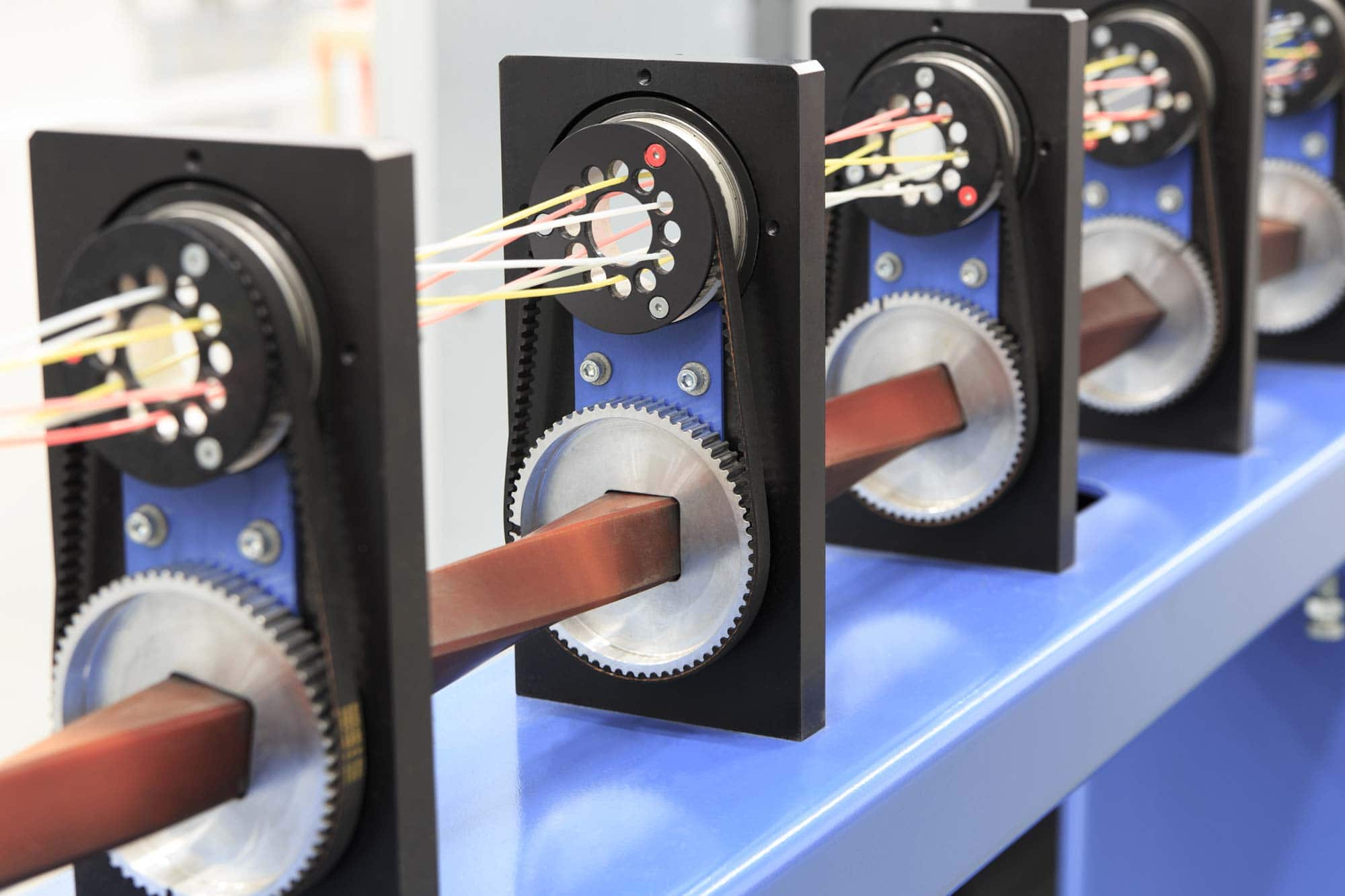

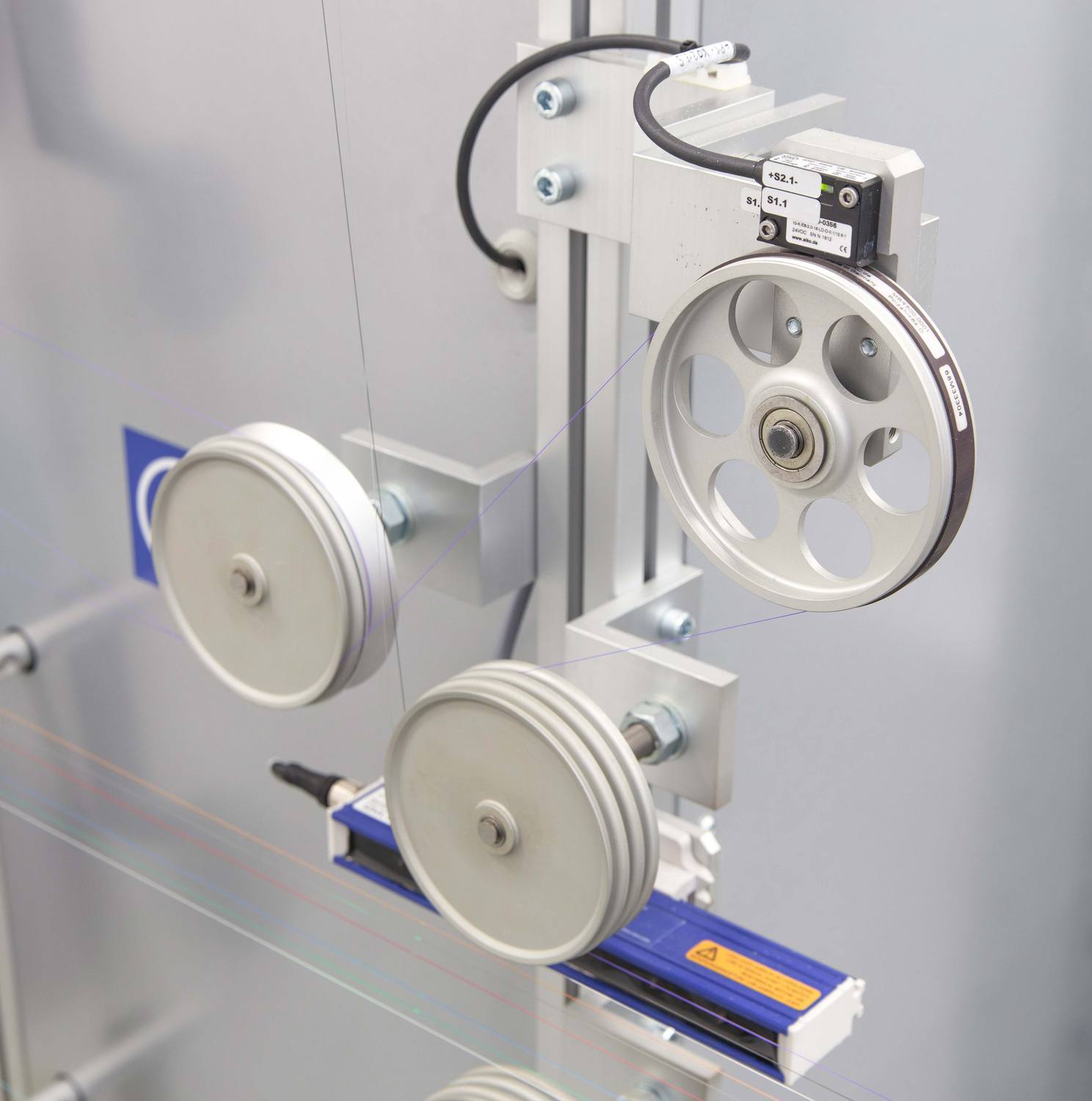

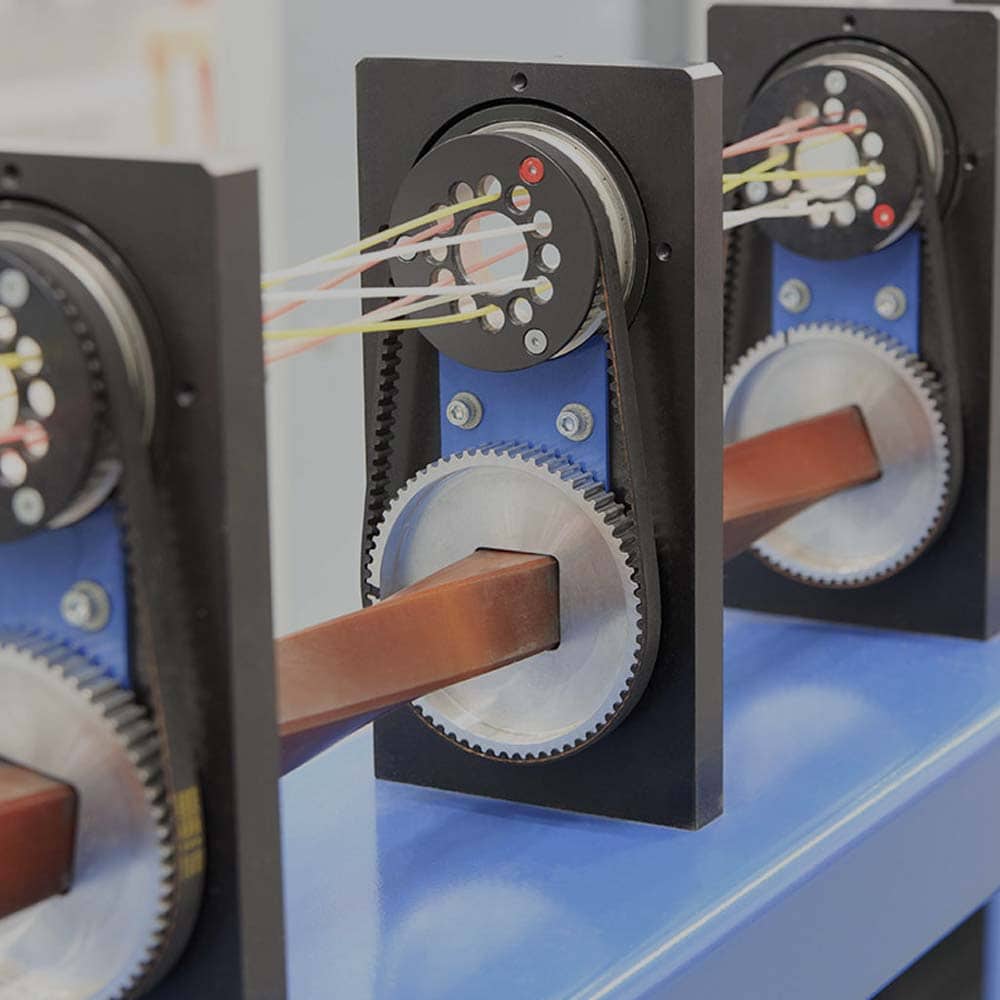

Low-tension binder for single and dual-end yarns

Adjustable and precise binding tension with speeds of up to 4,500 rpm

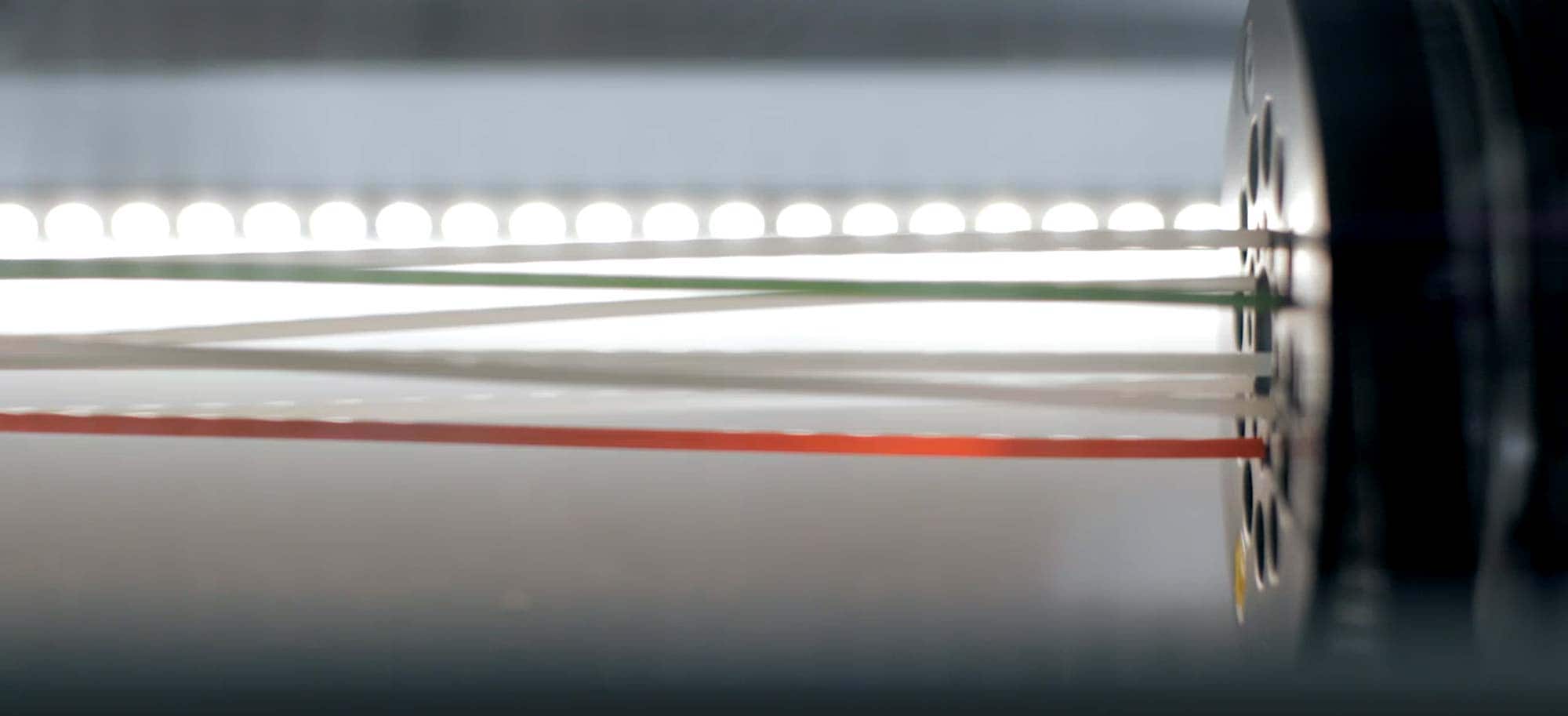

quality control

Monitor the excess fiber length online

With the help of our EFL monitoring system, you can now assess the quality of the running product online. To do this, we have integrated high-resolution measuring devices directly into our loose tube line.

Our RIO line control then calculates the excess fiber length and reports on it in real time. That allows you to detect deviations in fiber length already during production and to reduce your scrap rate accordingly.

leading expertise

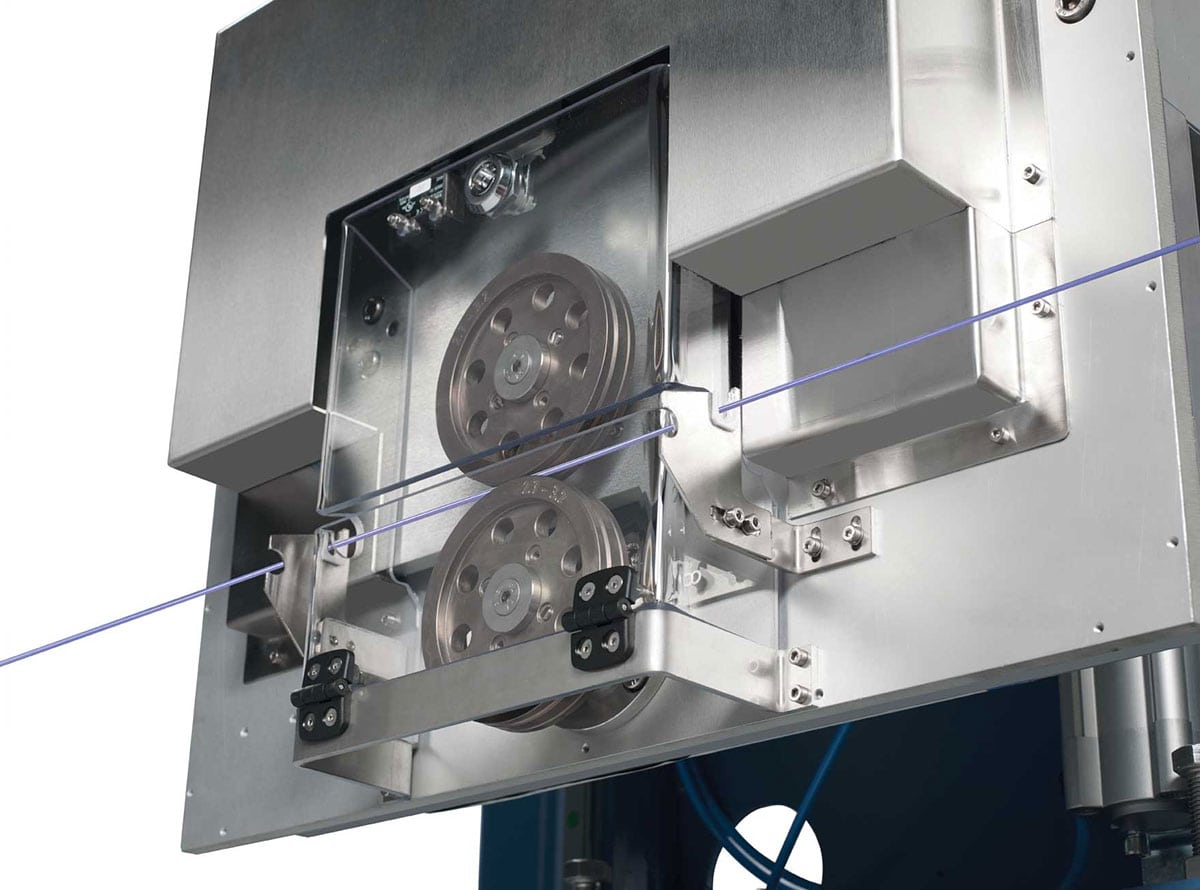

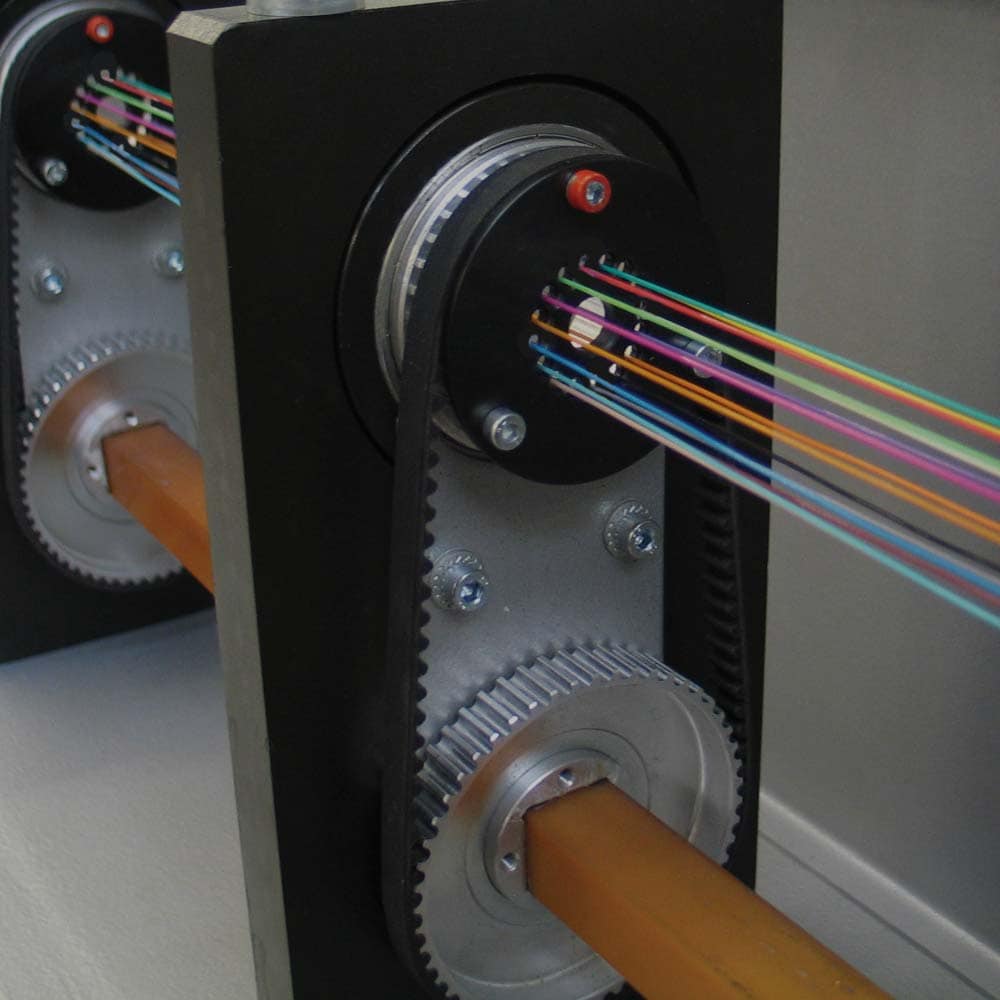

Unique stranding technology

High production speed, long batches, reduced setup and downtimes take SZ stranding process productivity to a new level.

Our efficient SZ stranding technology is designed to manufacture fiber optic al cables for a wide range of indoor and outdoor applications.

The stranding process guarantees low stranding tension fluctuation, accurate and stable lay length, and constant binding tension in all circumstances.

overview

Customized production lines for

fiber optical outdoor cables

Acquire reliable equipment to produce optical cables for outdoor applications. Our machines win customers over with their outstanding quality, high production speed, and flexible handling for various product designs.

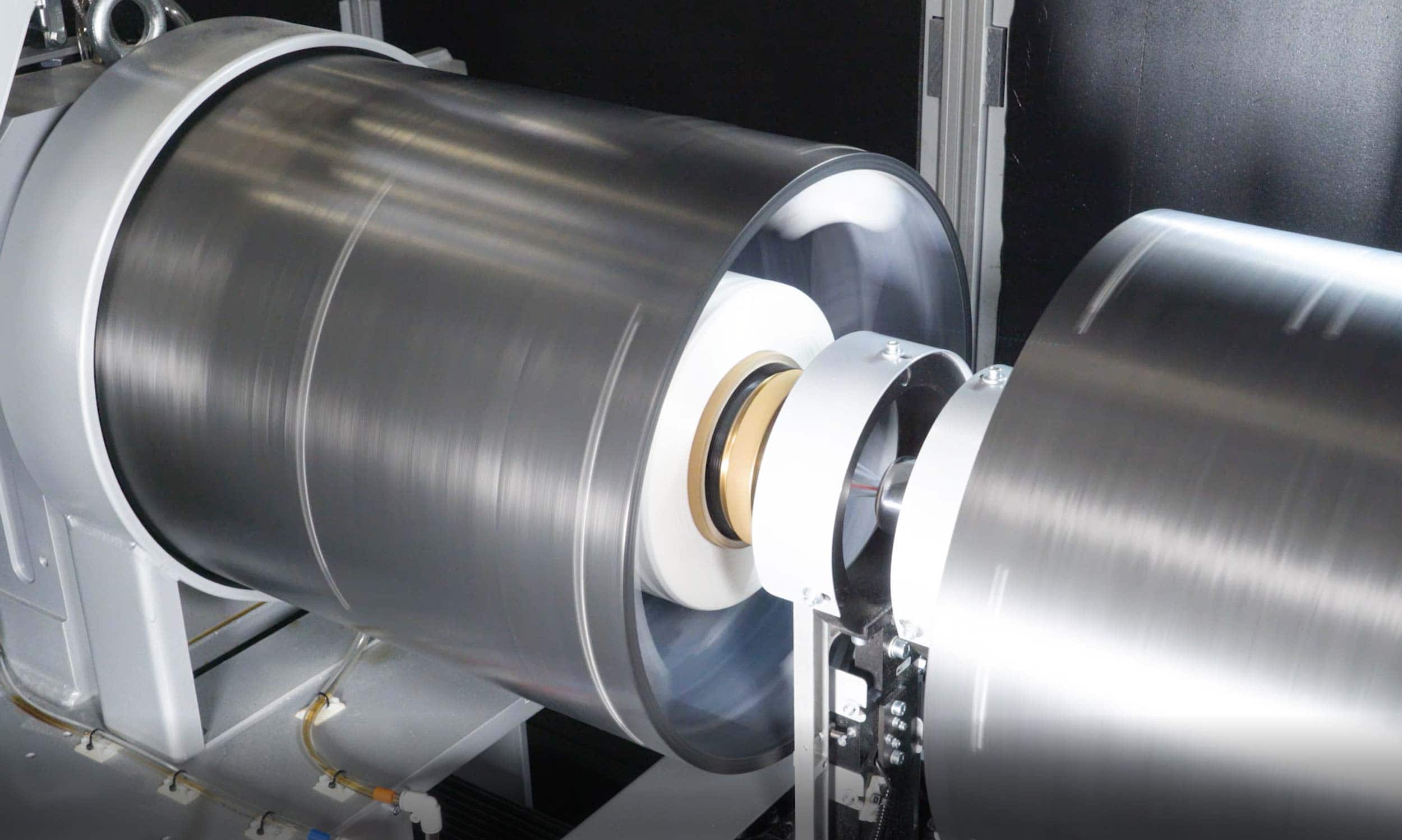

RL-R

Loose-tube production line

Highly efficient production of single/dual-layer and jelly/dry tubes

RL-V

SZ stranding line

Unique technology for single and dual-layer stranded product designs

RL-M

High-speed jacketing line

Proven and reliable technology for a wide range of fiber optical cables

overview

Customized production lines for

fiber optical indoor cables

Get everything you need for the efficient manufacturing of fiber optic indoor cables of top quality. Our machinery is specially designed to meet the demands of a wide range of products.

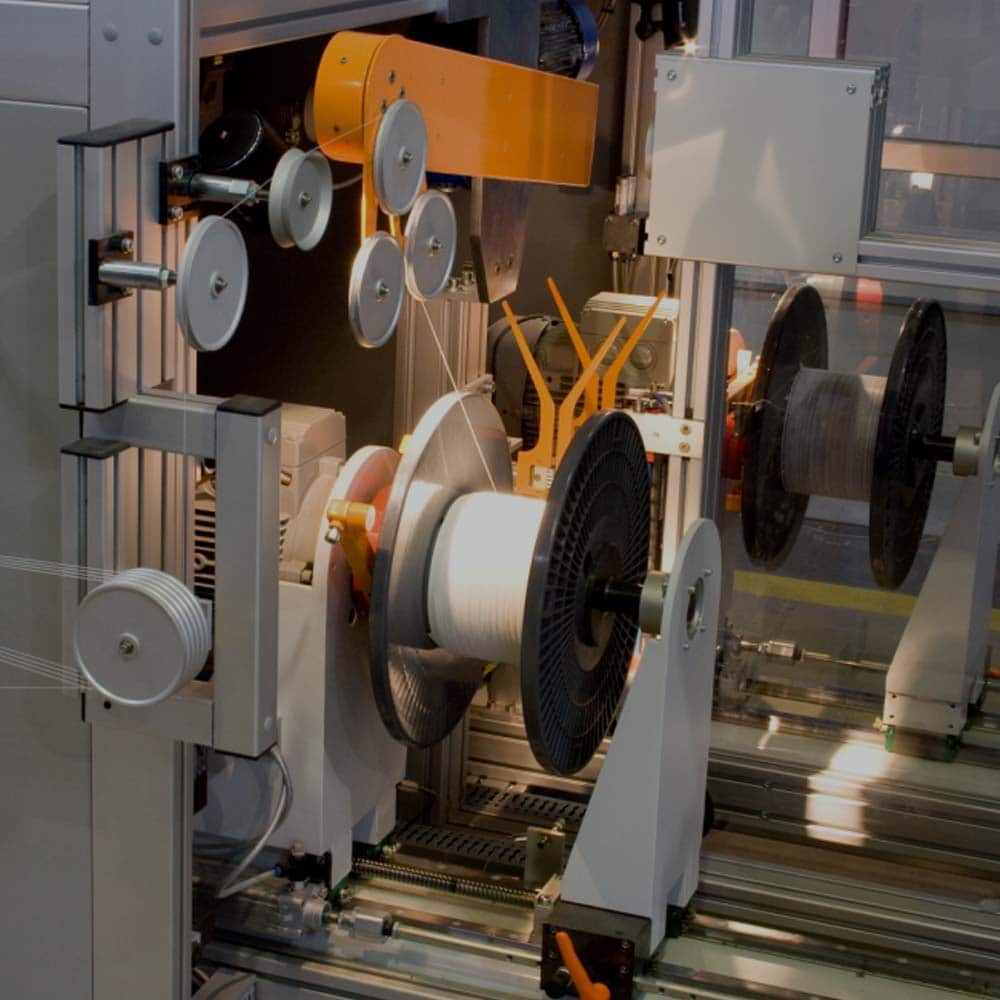

RL-T

Tight coating extrusion line

For tight buffer, semi tight buffer, and micro sheath extrusion

RL-P

Premises cable line

For the production of fiber optical patch cords, distribution, break-out and FTTH drop cables

contact

get in

touch

with us

Are you looking for more flexibility in your manufacturing process? Do you want to improve your cable performance or optimize your process to reduce scrap?

Get in touch with our experts for in-depth information on our manufacturing solutions for fiber optical cables.