production equipment

our current machinery provides precision at every stage of the process

precision manufacturing at every stage

Precise testing and optimization of battery module production processes under realistic conditions.

Each system is tailored to specific requirements and production steps and is briefly introduced below. The systems currently in operation enable welding processes with spot sizes ranging from approximately 45 to 640 µm and laser power outputs between 150 and 8000 W, using different beam profiles. This versatility makes them suitable for a wide range of materials and thicknesses.

Each of these systems ensures that all manufacturing processes — from prototyping to small-scale series production — are carried out efficiently and safely. By utilizing cutting-edge technologies, we deliver precise, high-quality results at every stage of the production process.

focus on flexible prototyping

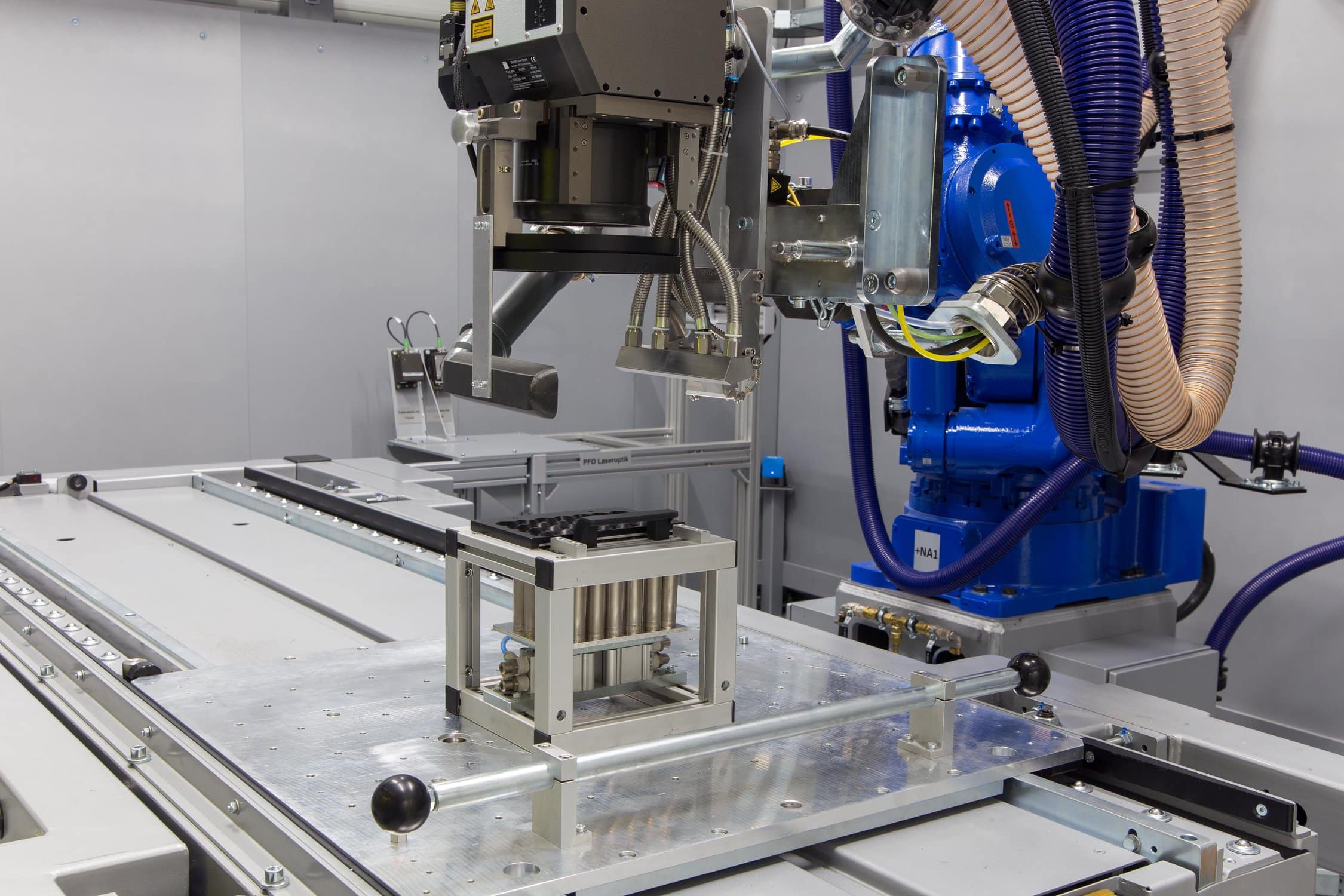

BMe weld - laboratory

1.5 kW single-mode

Our Laser Welding Unit is a prototype welding system designed for flexible battery module processing. Equipped with a 1.5 kW IPG single-mode laser with a 26 µm fiber core and a 6 kW multi-mode laser with a 50 µm fiber, it covers a wide range of materials and components.

- the system features a portal axis setup for precise positioning and cost-efficient control

- options for SCANLAB IntelliWeld II PR and IPG HighPower scanners, including automated optical part recognition via Blackbird’s Scavis

- additional features include process monitoring for weld quality assurance, flexible clamping options, and safety measures like a mist extinguishing system and evacuation box for rapid cooling and product evacuation

focus on energy storage systems

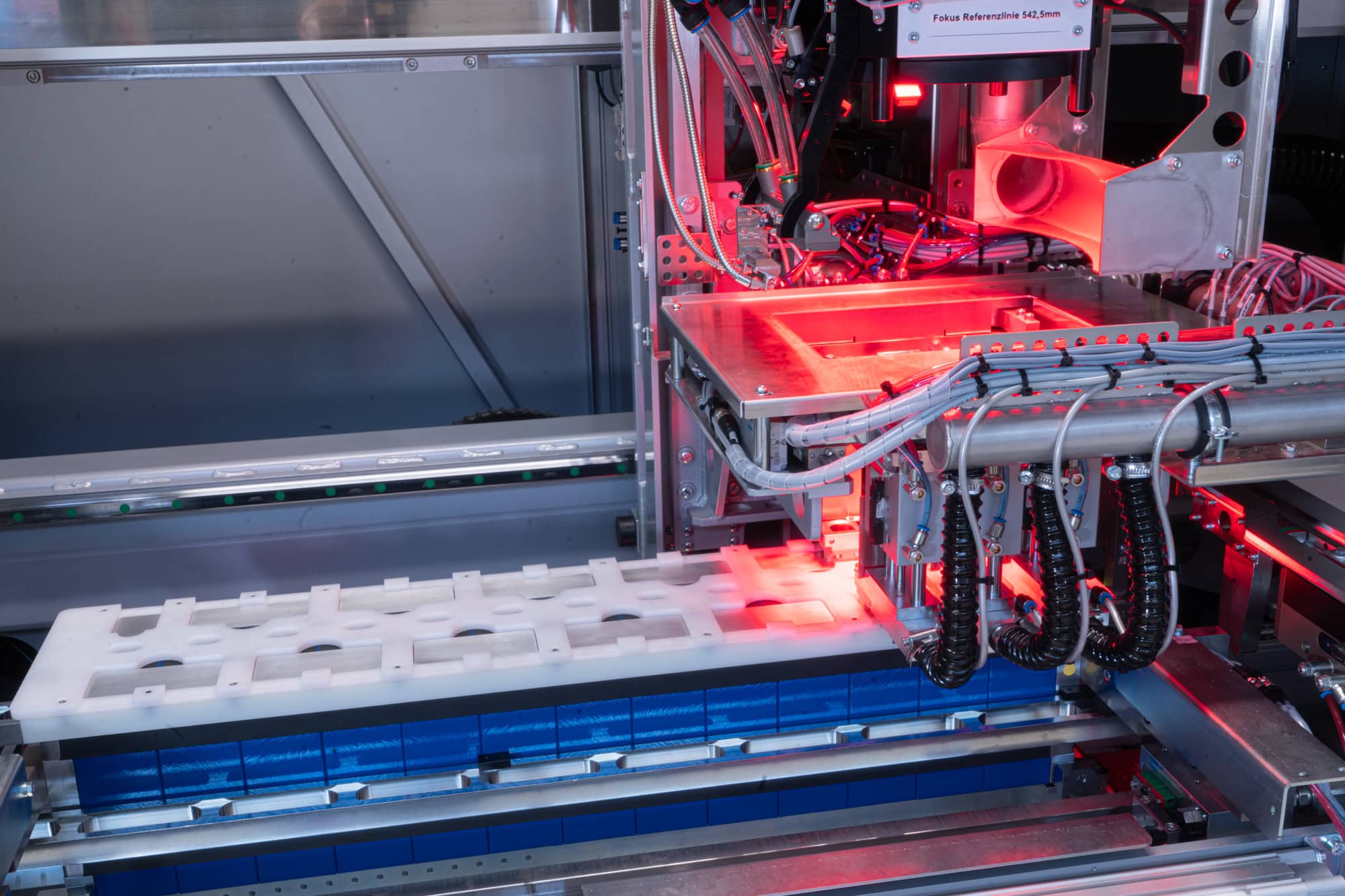

BMe weld - busbar

8 kW multi-mode

Our Laser Welding Unit is a specialized series welding system developed for the production of ESS storage modules. It operates with a powerful 8 kW Trumpf multi-mode laser source and a 50/200 BrightLine fiber, enabling precise and reliable welds even under demanding power requirements and for a variety of dissimilar material combinations.

- automated clamping system with individually adjustable tools

- accurate compensation for geometric deviations caused by cell or stacking tolerances throughout all production phases

- Trumpf PFO33-3 scanner with process monitoring and AI-based image recognition for consistently high weld quality and process reliability

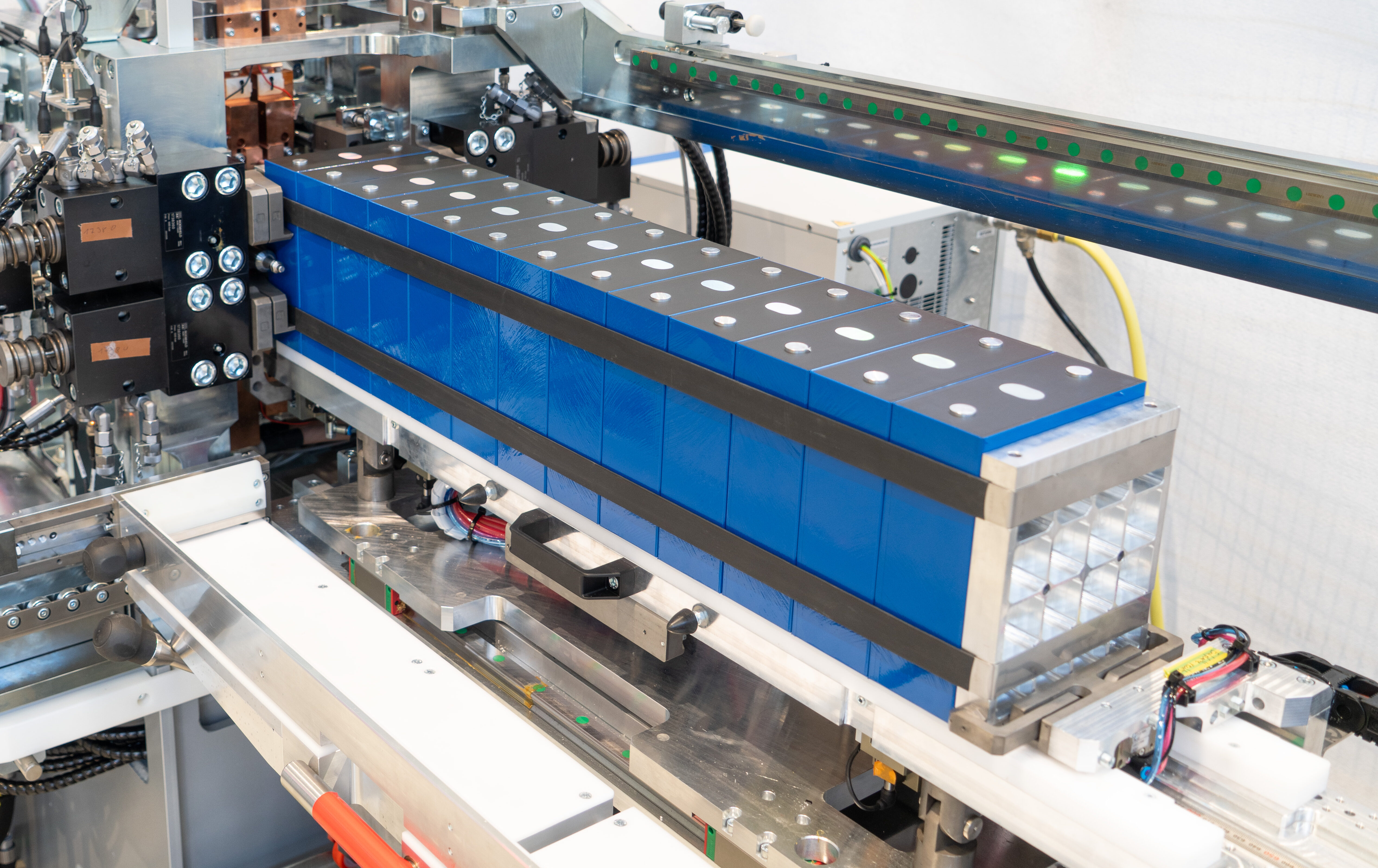

module strapping unit

BMe strap for safe and reliable BESS module production

At the core of the system lies resistance spot welding, enabling strong and durable joints. Combined with precise parameter control and a high degree of automation, the BMe strap results in stable and consistend quality, by controlled and repeatable processes and short cycle time. This makes it ideally suited for large- and medium-scale series automatic production.

contact

get in

touch

with us