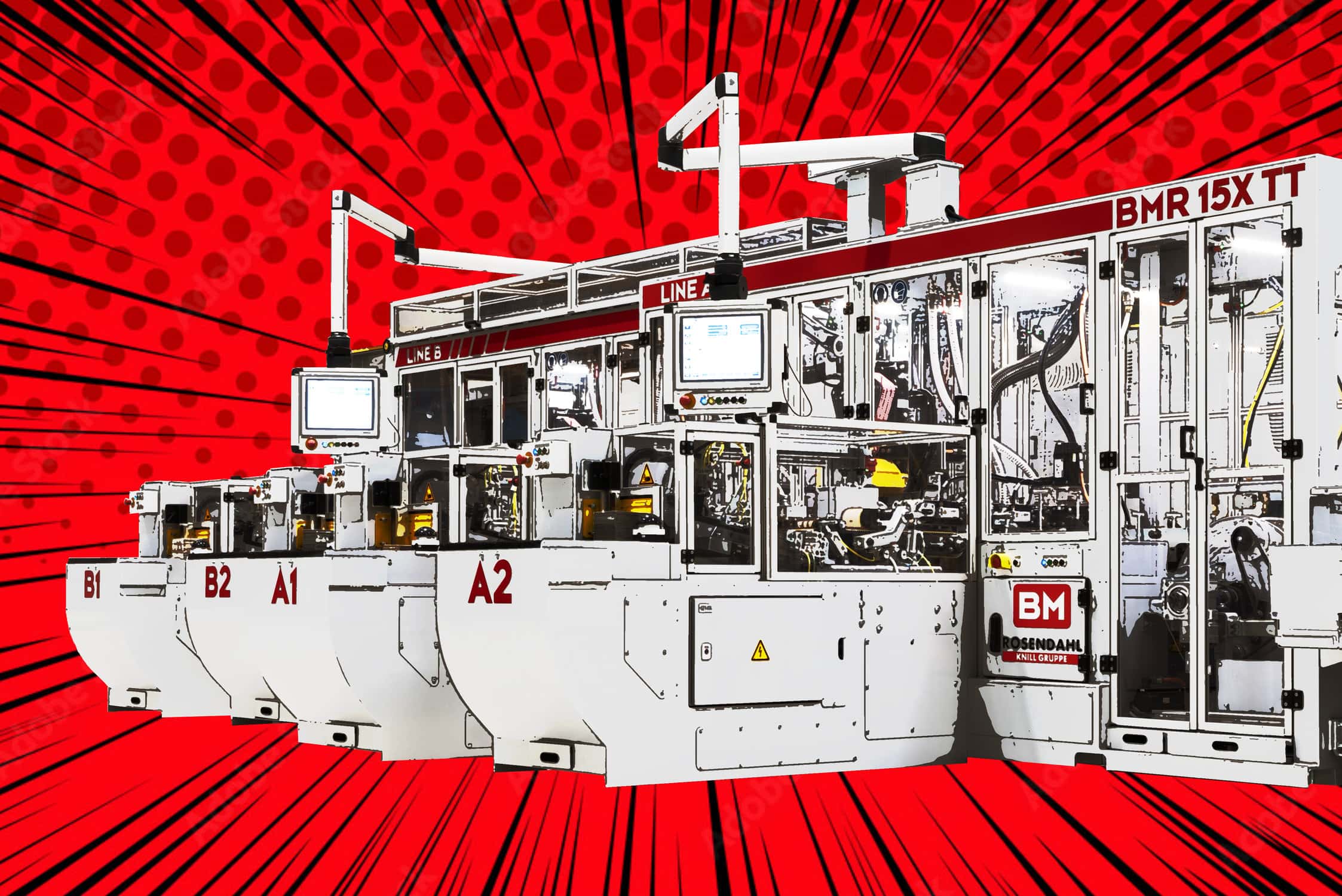

As the demand for electric mobility grows, BM-Rosendahl provides innovative solutions for on-road lithium-ion battery production equipment. Our flexible and scalable assembly lines support the production of battery modules and packs.

We cover solutions from small scale sampling to large scale serial battery production in these application fields:

- Electric Vehicles (EVs) and Plug-in Hybrid Electric Vehicles (PHEVs)

- Buses and commercial fleets

- Trucks and delivery vehicles

- Two- and three-wheelers

battery assembly expertise

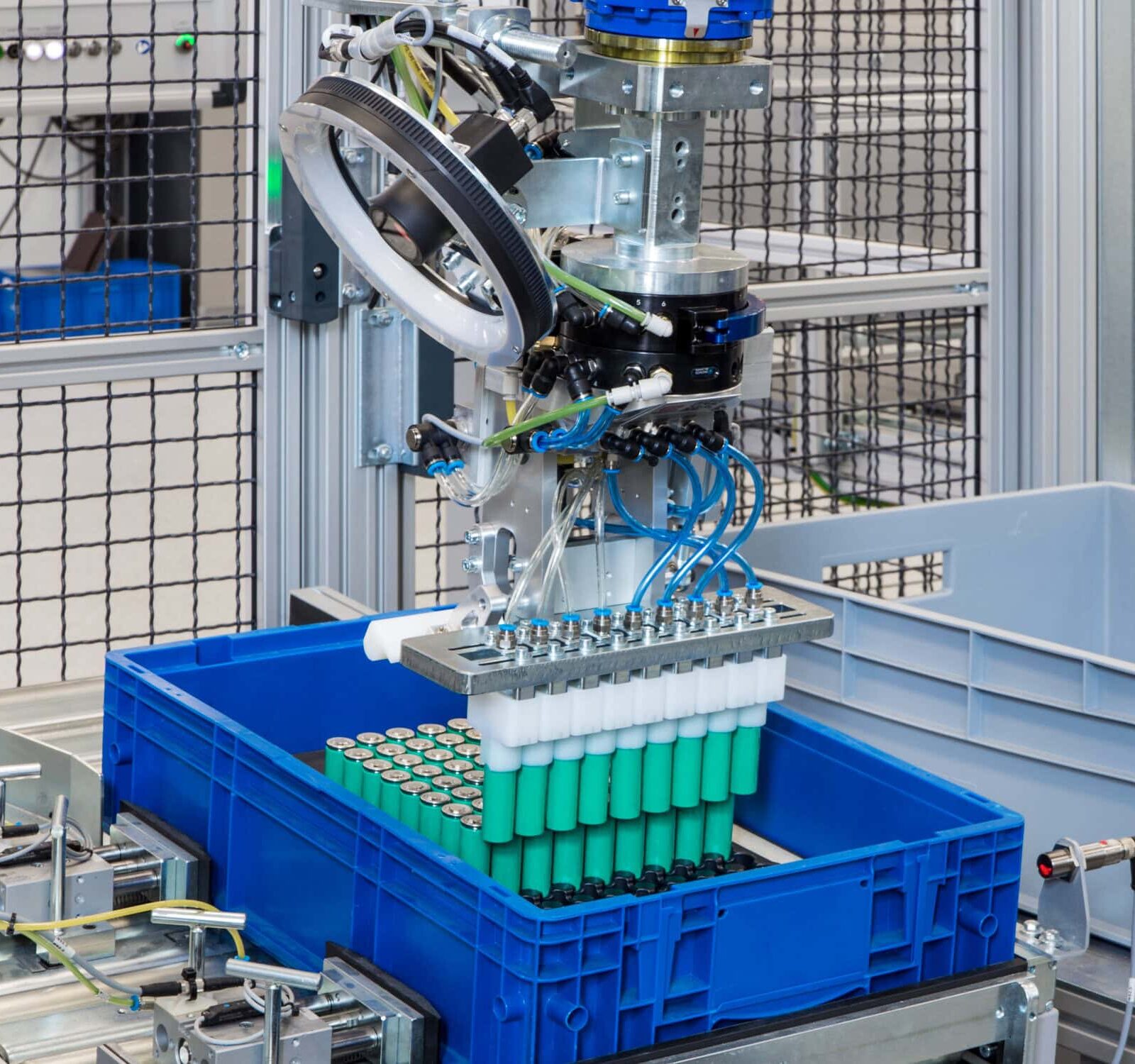

Our manufacturing equipment ensures high-quality battery production, covering key processes such as:

- Initial Testing & Identifying: Guaranteeing cell quality for efficient energy output

- Cleaning & Cell Handling: Precision handling for defect-free assembly

- Stacking & Compressing: Optimizing space utilization and energy storage

- Framing & Welding: Enhancing battery structure for safety and longevity

- Gluing & Filling: Providing stability for on-road performance

- Bolting & EOL Testing: Ensuring compliance with industry standards

BM-Rosendahl’s battery manufacturing solutions

empower the transportation industry with reliable, high-performance battery packs,

driving the future of sustainable mobility.

Let us tell you more

New magazine "charge up" out now!

Take a look on our fresh ideas and our technology solutions for lithium-ion or lead-acid battery production! Our bi-annual magazine shares insigths on the market, our developments and what's good to know.

5-step checklist for your ideal production line

Are you planning to invest in lithium-ion or sodium-ion battery manufacturing equipment? We have developed a detailed 5-step guide to help you clearly define your vision of an ideal production line.

News & Events

contact

get in

touch

with us