laser welding parameter development

our 7-step process to identify optimal

laser welding parameters

why laser welding parameter finding matters

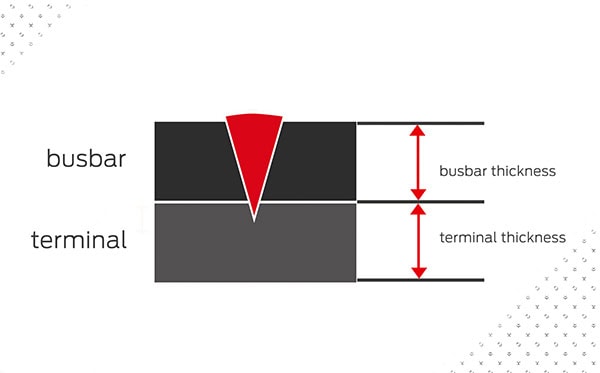

The welding quality of busbars is one of the most critical aspects of a battery system.

In lithium-ion battery manufacturing, the quality and reliability of laser-welded busbars are absolutely critical. These welds play a direct role in the overall safety, efficiency, and longevity of the battery system.

Poor weld quality can lead to electrical failures, increased resistance, heat generation, or even safety hazards like thermal runaway. As battery systems become more compact and energy-dense, the margin for error in weld quality shrinks significantly.

Once the production line is performing it is mandatory that the process must be inherently stable and optimized to ensure consistent, high-quality results across thousands or millions of units.

That’s where our laser welding parameter optimization service comes in. We offer a structured, data-driven approach to laser welding process development specifically tailored for customers in the li+/na+ battery sector.

Our proprietary 7-Step optimization framework ensures that the welding parameters used on your production line are fine-tuned for maximum quality, repeatability, and process stability.

This service is ideal for:

Battery pack and module manufacturers

Tier 1 and Tier 2 automotive suppliers

Energy storage system integrators

Any organization scaling from prototype to serial production

Our deep expertise in laser welding, metallurgy, and battery design allows us to guide you through each stage of optimization — from material characterization to production-ready process documentation.

Below, we’ll walk you through our 7-step process in detail and show how it ensures optimal welding performance while reducing risks during ramp-up and serial production.

we help to ensure reliable, safe, and high-quality battery systems

René Wund

in 7 steps to your perfect laser welding parameters

step 1

define your cell design

We ensure accurate parameter development based on the specific cell design. We therefore need all information on your cells, the terminals and all its components. This builds the base for all subsequent steps. Ideally, you provide us with the components from your preferred supplier so that the basic material comes close to your final cell components as possible.

step 2

laser welding requirements

We align on clear, achievable welding objectives. This step is often underestimated to how we achieve the best possible welding parameters. In defining your individual specifications and your welding goals, we can start first tests on your desired product. Here you provide us with your wish list, so to say. This is the point where your product design theoretically meets the final perfect battery and which tests it has to withstand and pass.

step 3

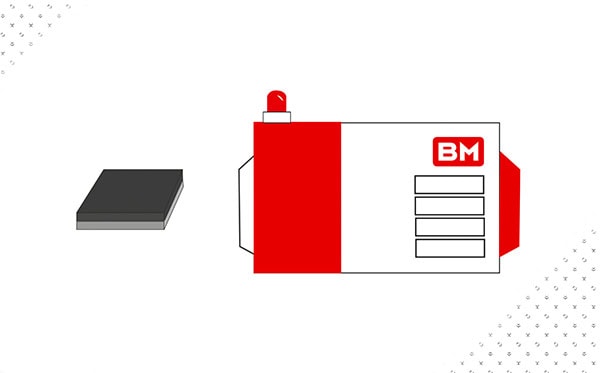

tests with raw material

We start conducting safe, controlled parameter tests without risking valuable components. You can view it as a trial and error process where we step by step narrow the parameters down to the perfect fit. The test raw material is ideally provided by the you and your cell supplier and represents the cell material in appropriate thickness. Starting with these first trials also first tests are conducted.

step 4

dummy cell testing

Now we are coming close to the desired goal. We validate parameters under realistic conditions. When parameters are found for the test material, we start over with test cells and go through all testing phases and fine tune the process.

step 5

real product testing

We confirm that the welding parameters are effective and reliable. We achieve final parameter verification using real cells to simulate real production conditions.

step 6

delivering specifications and test reports

We provide you with a clear, actionable roadmap for implementation. This comprises of a detailed documentation on achieving optimal results — including shape, technology, and materials. Also, you will receive a documentation on what does not work through our trial and testing phases.

step 7

prototyping at BM-Rosendahl

We offer hands-on experience with the validated parameters, ensuring smooth transition to serial production starting with prototyping in our in-house laboratory.

how we support - in brief

developing reliable laser welded joints

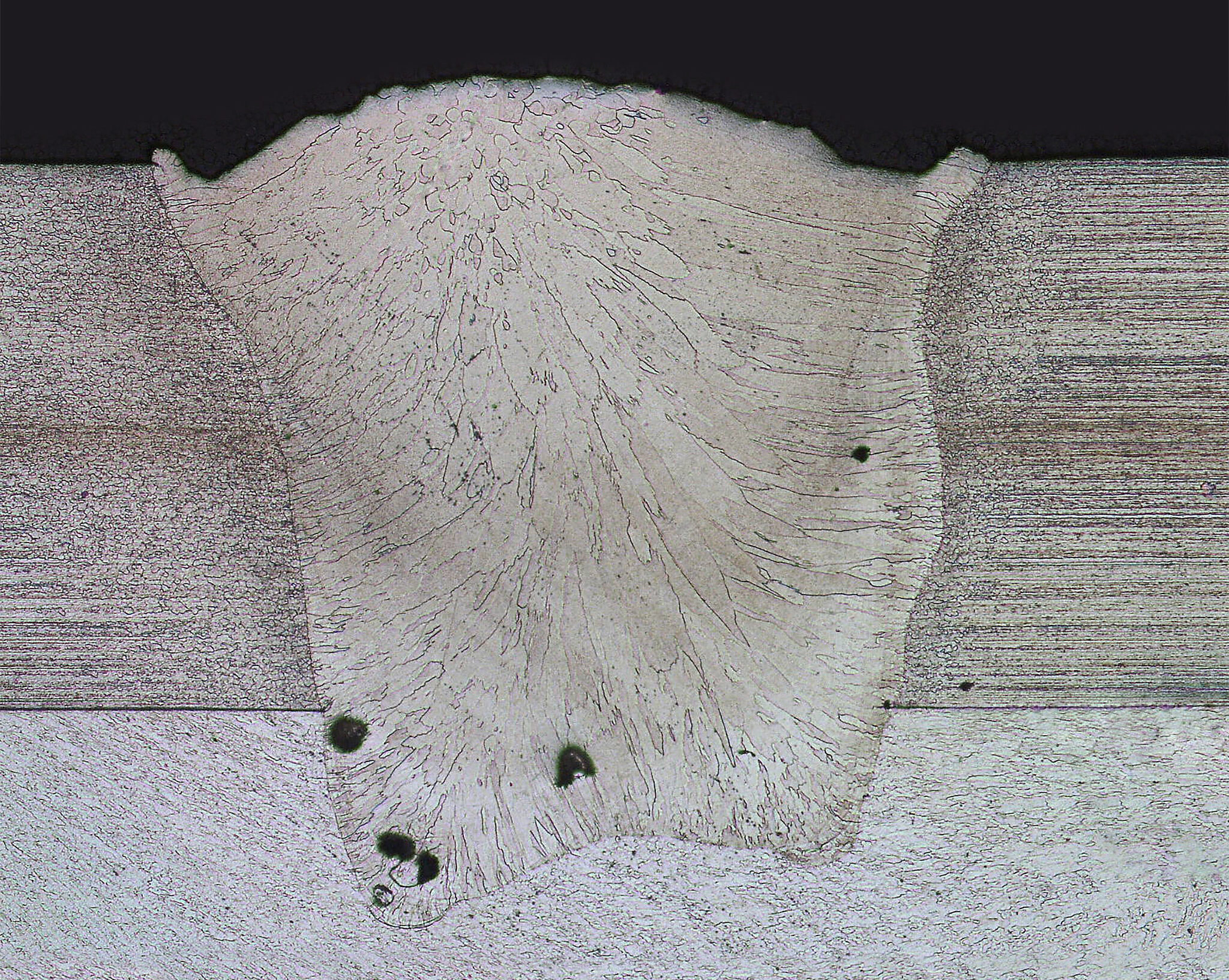

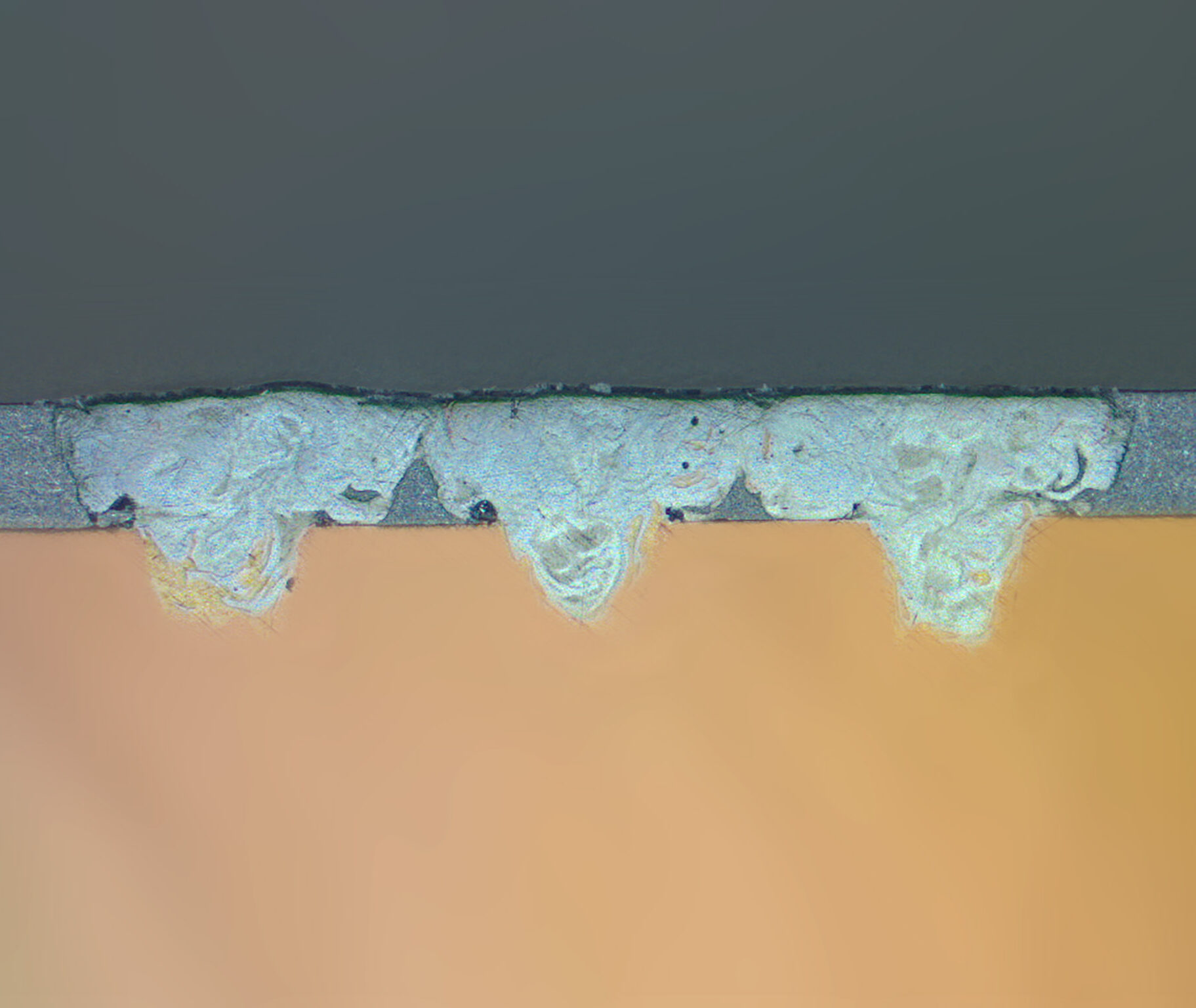

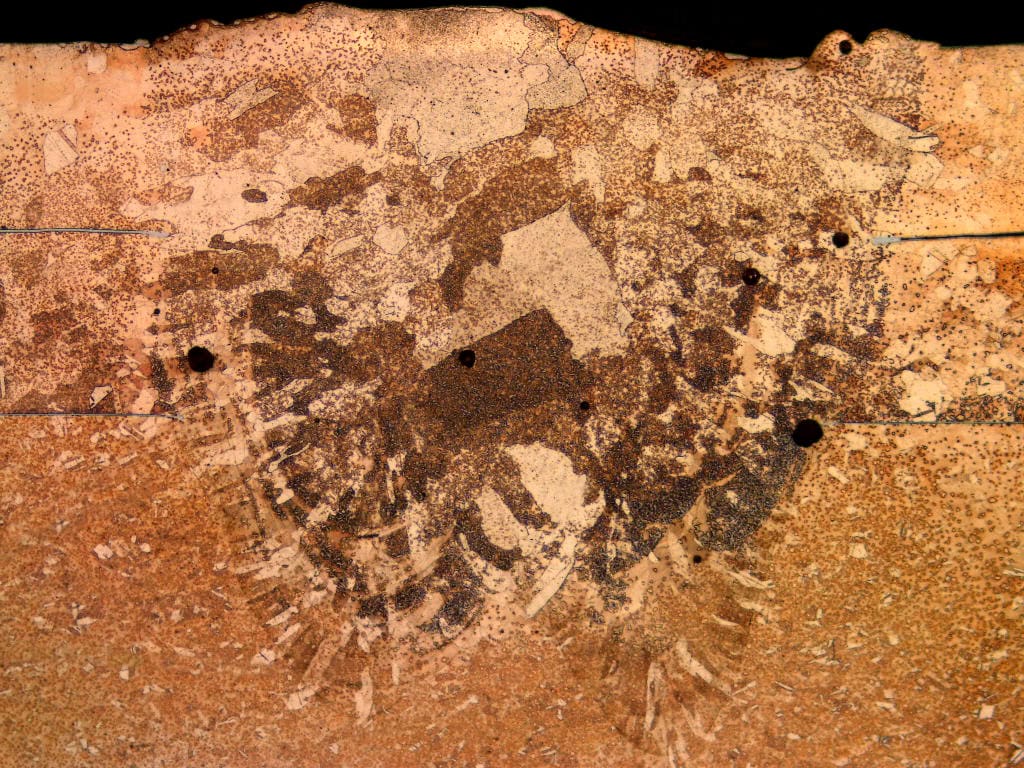

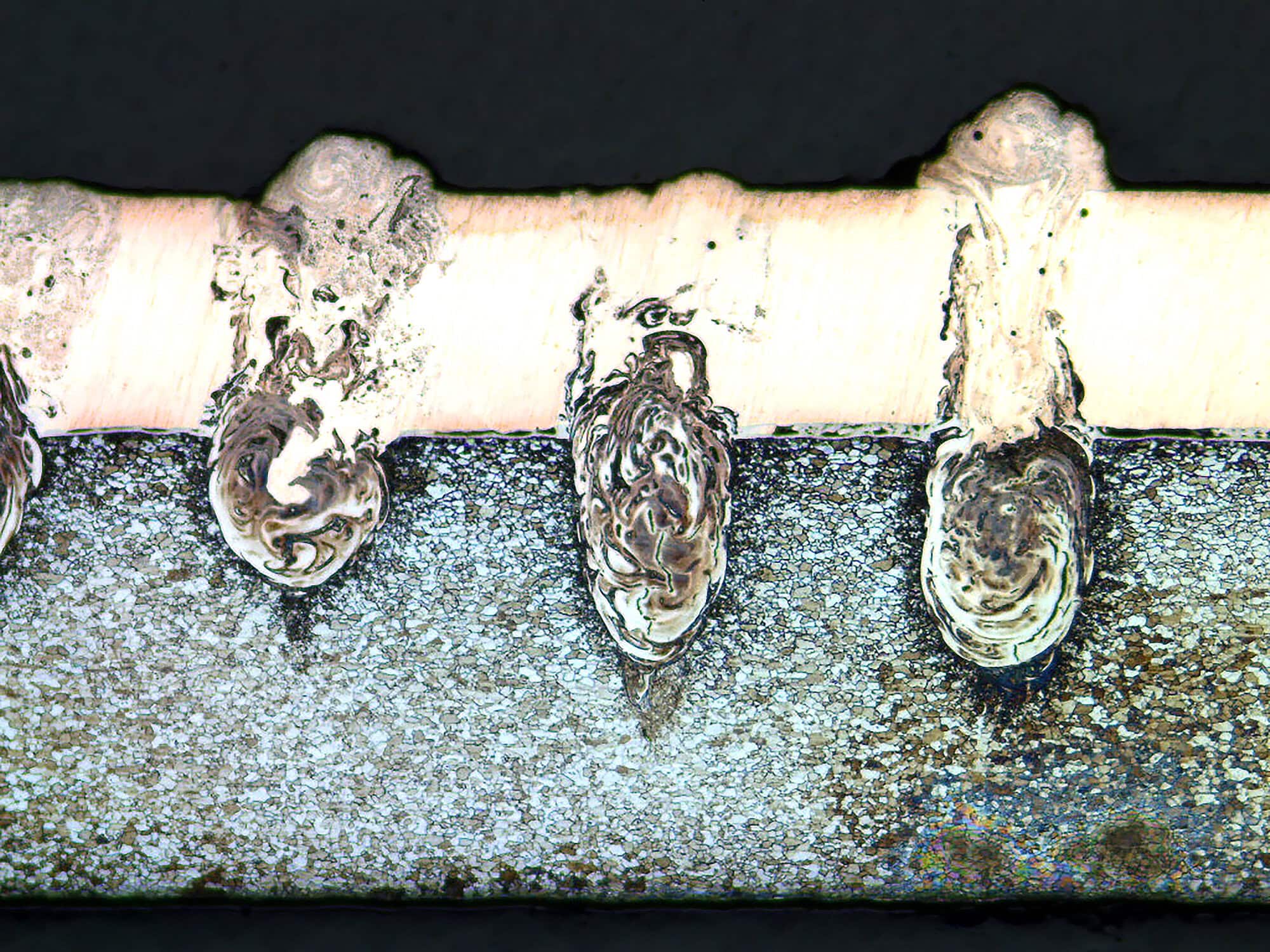

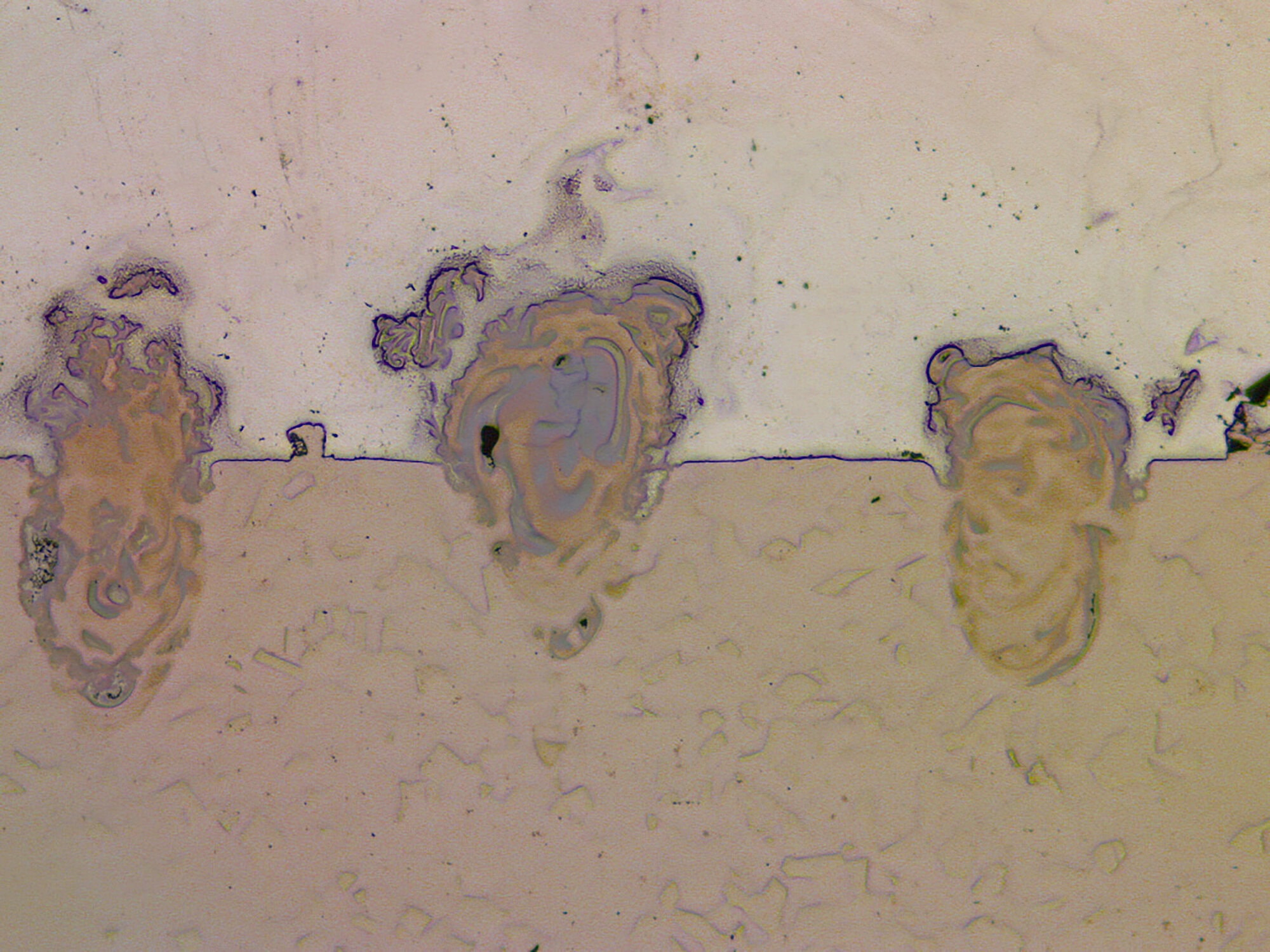

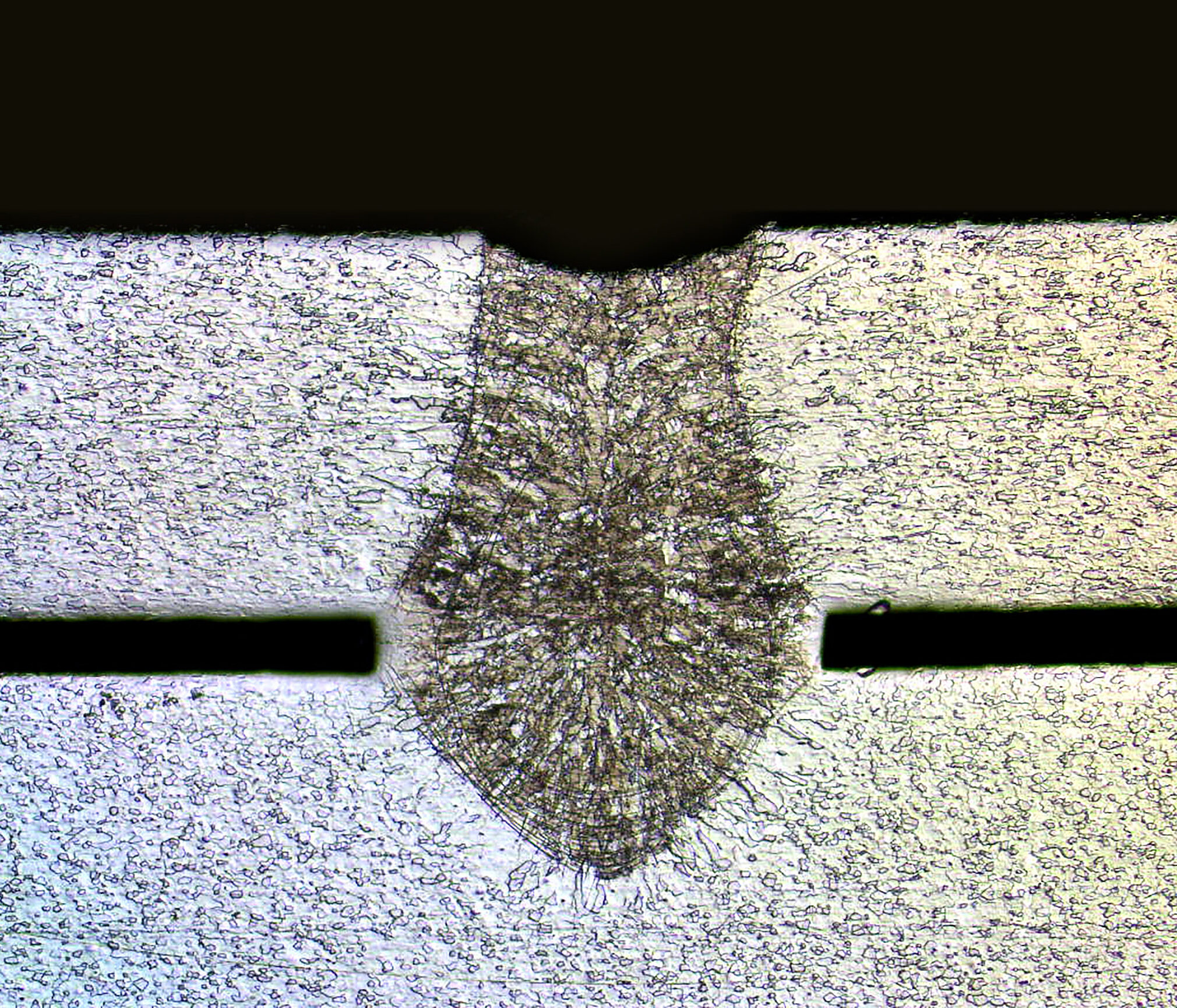

The development of process-reliable laser welds is particularly challenging when working with dissimilar material combinations. We offer extensive experience in analyzing, evaluating, and optimizing such joints – from selecting and fine-tuning suitable process parameters to ensuring quality through metallographic and electrical testing.

Al-Al

this pairing requires that pore formation and spatter must be avoided

Al-Cu

this combination demands highly precise process control due to differing melting points and thermal conductivities

Cu-Cu

(coated or uncoated), our focus is on minimizing variations in penetration depth caused by keyhole fluctuations, contact resistance, and spatter

Fe-Cu

this pairing requires precise energy input which is essential especially with coated materials to avoid uncontrolled mixing zones or, in the case of zinc coatings, evaporation and cracking

Fe-Al

most technically demanding combination where we carefully analyze and assess the formation of intermetallic phases to ensure both mechanical and electrical reliability. Especially in terms of strength (static and more so dynamic), compromises are often unavoidable with this material pairing

Fe-Fe

generally more forgiving, but with the same requirements as for Fe-Cu.

Our strength lies in the combination of state-of-the-art laser technology, deep materials science expertise, and robust testing methods

testing expertise for battery modules

destructive and non-destructive analysis

In our state-of-the-art laboratory, we offer comprehensive testing procedures tailored to battery module manufacturing – with a focus on analyzing the various types of joints and base materials commonly used in this field.

Our portfolio includes both destructive and non-destructive testing methods to ensure the quality and reliability of your products. Our laboratory equipment is continuously expanded and adapted in line with current project requirements.

what our expert says

battery systems.

contact

get in

touch

with us