SK-410-C

Detecting color variations at a speed of 2,400 m/min seems impossible? It isn’t.

In automotive wire production, just one tiny granule of a different colour can cause a contamination of approximately 200m of precious wire product. And at a speed of 2,400m/min it takes only 5 seconds for these 200m to disappear in a reel. Now you can detect that:

With the innovative SK-410-C 360° sensor system, you can detect color deviations unperceivable to the human eye. Thanks to immediately assured color reliability, color claims and faulty productions are now a thing of the past.

suitable for high-speed applications

easy handling and integration

insensitive to water drops and rotation

improve your color quality or reduce your master batch with objective color assessment

The SK-410-C continuously monitors the color quality by measuring the main and stripe color as well as the stripe width. The color quality is logged in the reel report.

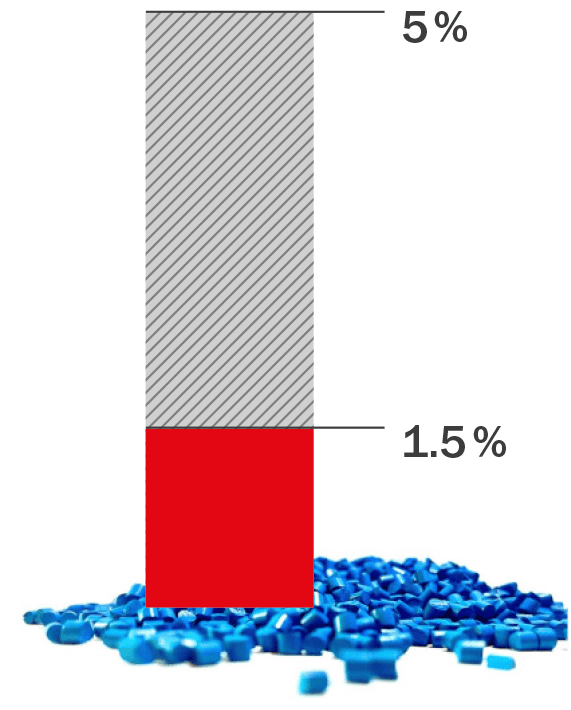

The results of intense testing and customer experience have shown that master-batch can be decreased down to 1.5%, while maintaining the same color shade and product quality.

Moreover, waste and scrap rates can be significantly reduced at start-up, color change and during production due to automated production sequences.

Neatless integration in RIO line control

Effortlessly manage your color settings within RIO line control and access real-time reports.

contact

get in

touch

with us