Quick color change

with ROCOMAT

Get one single perfect solution for all your demands within the color changing process for stripes, skin and layer.

Quick color change can be that easy

From red/blue to yellow/green in 0.3 seconds

- Small volume of melt is used during product change, which results in shortest scrap length during the color change.

- The color change is performed fully automatically.

- All bypasses are integrated in the ROCOMATSystem, no need of separate units.

- To save costly ready-sale stock, the ROCOMAT supports your just-in-time manufacturing.

- The system containing fine-tuned hardware and software components allows shortest production length and smallest batch size.

Change layer / skin / stripe color

Layer change

Skin change

Stripe change

Layer and stripe change

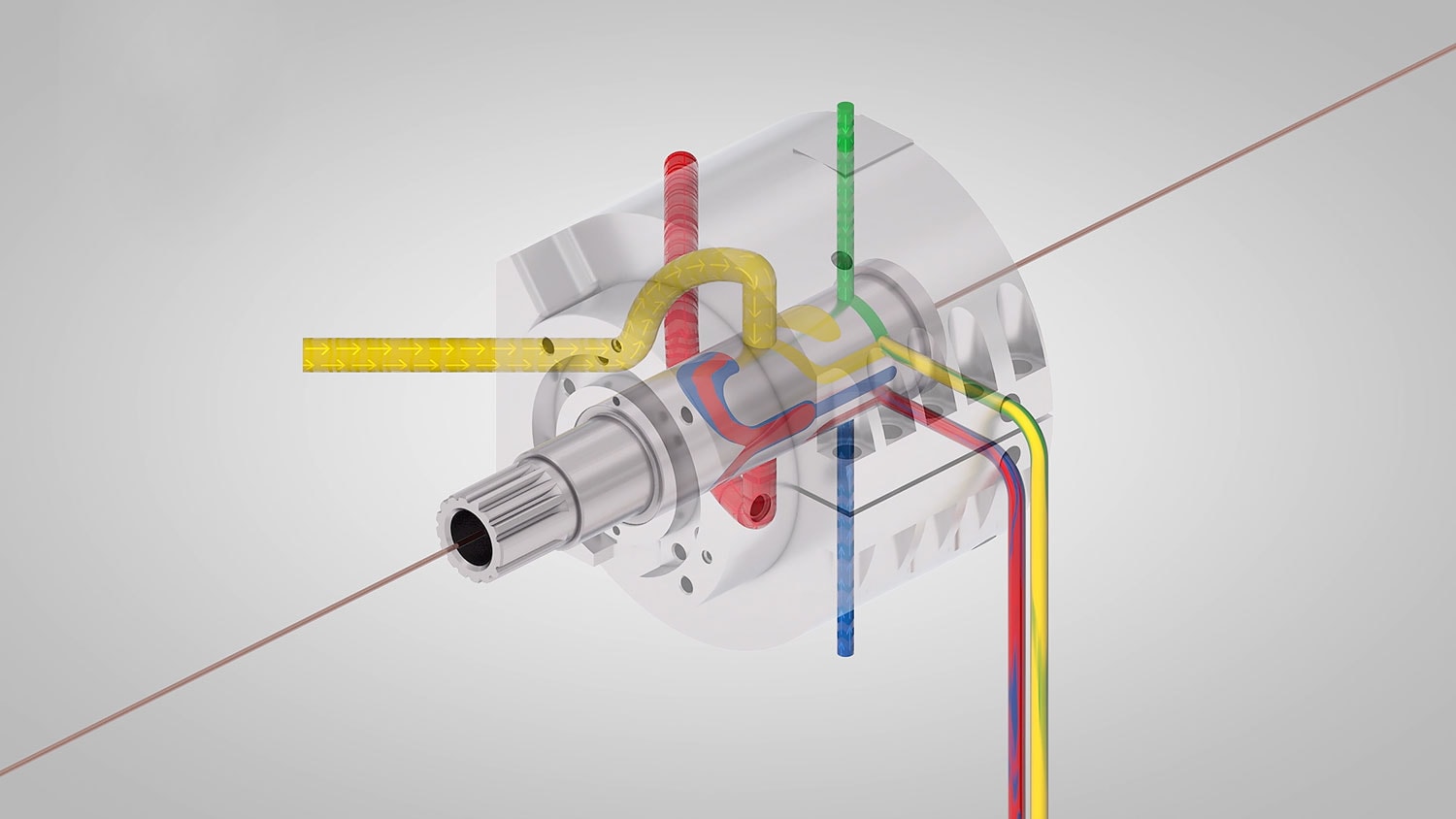

The ROCOMAT concept

How does a color change with ROCOMAT work?

The melt is delivered into the multi-layer crosshead ROCOMAT by two independent main extruders for the inner and outer insulation layers. Additionally, one or two stripe extruders can be connected. While the outer layer/stripe shows the actual color, the inner meltflow gets colored as needed for the next planned batch. Continuous melt-flow without valves prevent stagnation and blocking.

Colors change by switching the distributor in the ROCOMAT: only the volume in the distributor is used for color change.

The inner melt-flow with the new batch color becomes the outer layer. At the same time, the color change takes place unnoticed at the inner layer. In order to support the benefits of crossing-out the melt-flows, the material throughputs of the various layers can be varied.

Technical data

-

Core diameter 0.8 mm – 5 mm

-

Insulation diameter max 7 mm

-

Layer types Layer change, skin change, stripe change, layer and stripe change

contact

get in

touch

with us

Contact us if you are interested in high-performance equipment for automotive cable and wire production. We will be happy to answer your questions.