laboratory services

testing expertise for battery modules with destructive and non-destructive analyses

state-of-the-art laboratory

We offer comprehensive testing procedures tailored to battery module manufacturing. We focus on analyzing all types of joints and base materials commonly used in this field. Our portfolio includes both destructive and non-destructive testing methods to ensure the quality and reliability of your products.

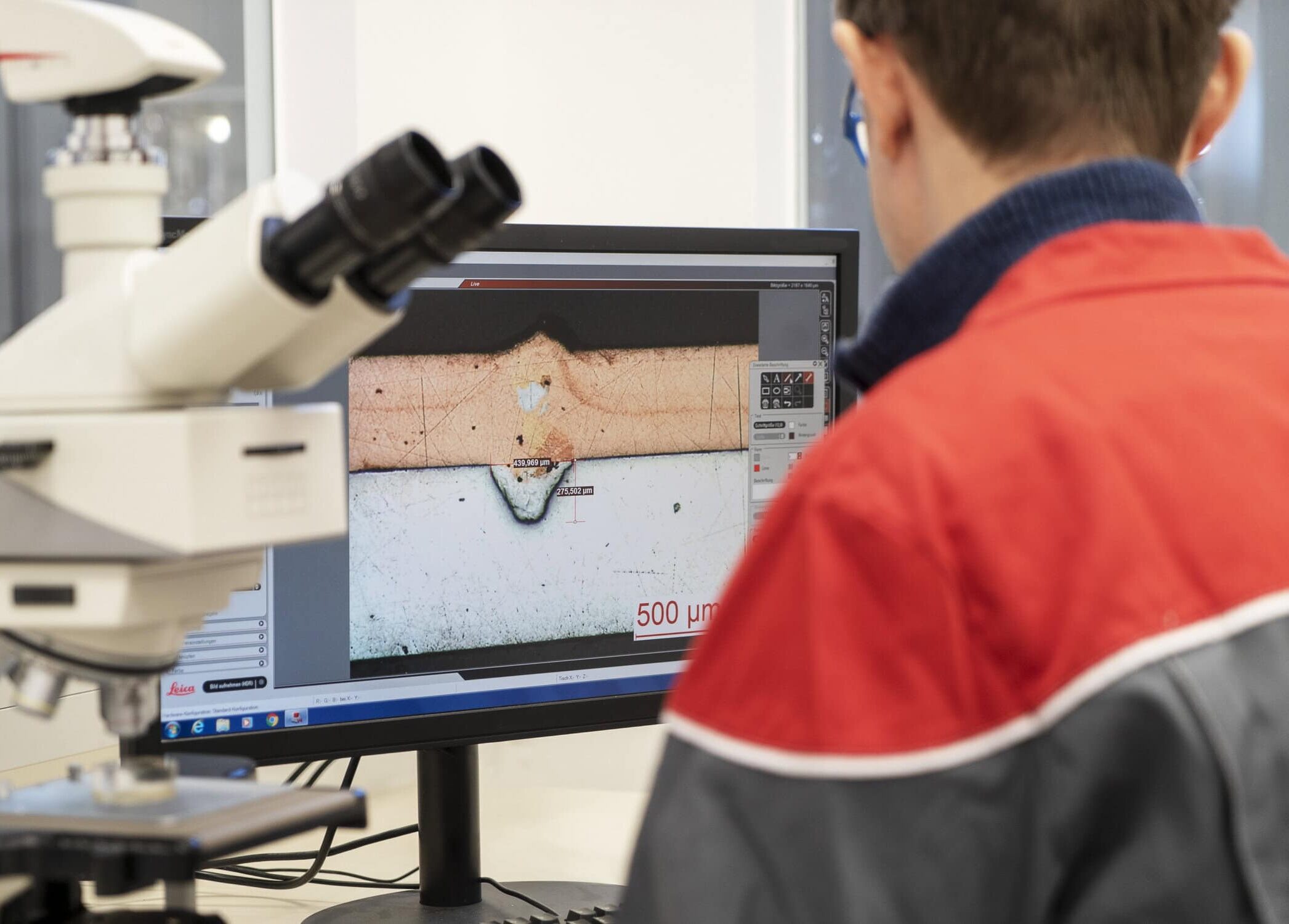

Microstructural Analysis via Metallographic Cross-Sections & Microscopy

Precise macro and micro sections, including all necessary contrast techniques and etching, for detailed structural and microstructural evaluation.Universal Testing Machine

Versatile testing capabilities such as tensile, compression, shear, and bending tests to determine the mechanical properties of your joints. A typical example is destructive shear and peel testing of busbar welds during connection parameter development.Surface Tension Measurement

For accurate determination of surface energy and the adhesive properties of materials.

Voltage drop measurements and contact resistance analysis (interface resistance) to assess electrical conductivity and connection quality.

Process capability analyses (CpK, CmK) for the validation of series production processes.

comprehensive quality evaluation for laser welds

These testing methods allow for reliable evaluation of all relevant quality characteristics of a laser weld – including penetration depth, bonding area, porosity, seam and bonding defects, as well as other critical structural features.

Our laboratory provides precise and dependable analysis to help ensure the quality of your battery modules throughout all stages of production. When needed, we also support you with our expertise in evaluating the available process window to develop robust processes that are less sensitive to parameter variations.

all from a

single source

For advanced analyses – such as scanning electron microscopy (SEM) with EDX analysis or 2D/3D X-ray inspections – we collaborate closely with renowned external partners and academic institutions to provide well-founded answers to even the most complex questions.

Thanks to this broad analytical capability, we can not only evaluate individual processes but also secure entire manufacturing workflows – from development and prototyping to small-scale production.

For ous this means: maximum transparency, top-tier quality, and reliable process security – all from a single source.

contact

get in

touch

with us