Wire 2026

when?

Apr 13th – Apr 17th, 2026

where?

Messe Düsseldorf | A60 | Hall 9 Stockumer Kirchstraße 61 Düsseldorf Germany

share

Visit booth A60 in hall 9

where machines, processes and people connect

At Wire 2026, we will showcase intelligent, automated solutions designed to address real-world challenges and boost productivity.

technology meets impact

Thinking about TPI or PEEK extrusion for magnet wire?

Looking for gas-tight metal shielding for your superconductor production?

Need for higher bandwidth pushing data centers toward optical fibers?

Sounds like a case for Rosendahl Nextrom.

Visit us at booth A60 in hall 9 to find solutions for that and more.

We are set to showcase innovations across the sectors energy, mobility and communication.

energy

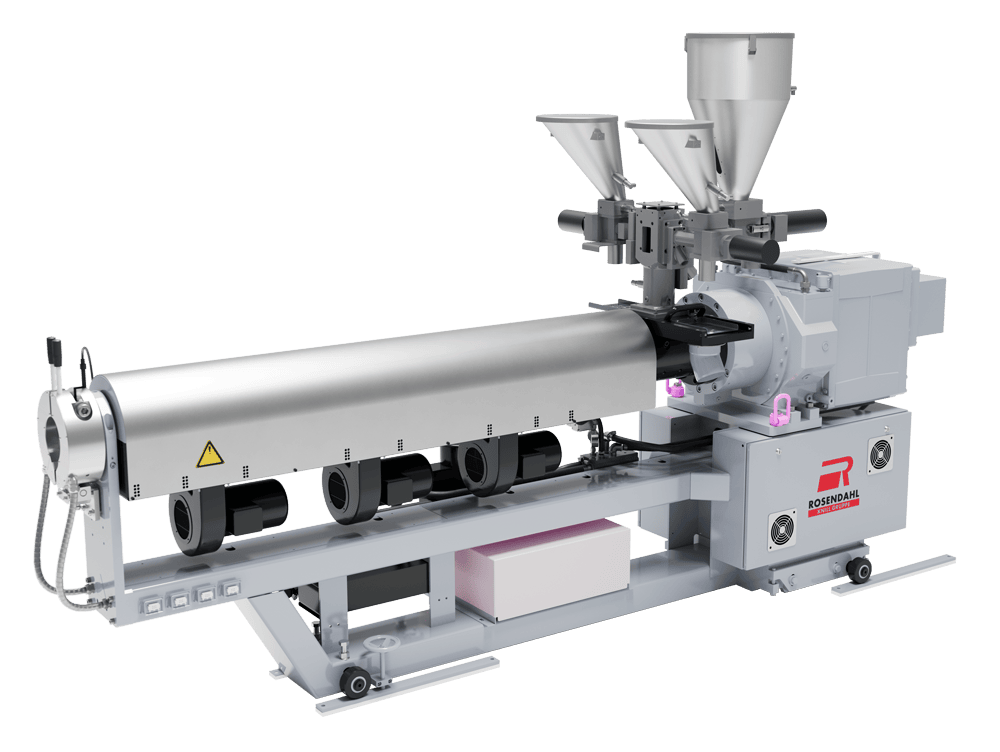

A new standard in high-speed insulation

Rosendahl introduces its first completely standardized high-speed insulation line. Cost-efficient, material-saving, and designed for the most common use cases, it reaches new levels in output and material performance – particularly in LSOH/HFFR processing.

mobility

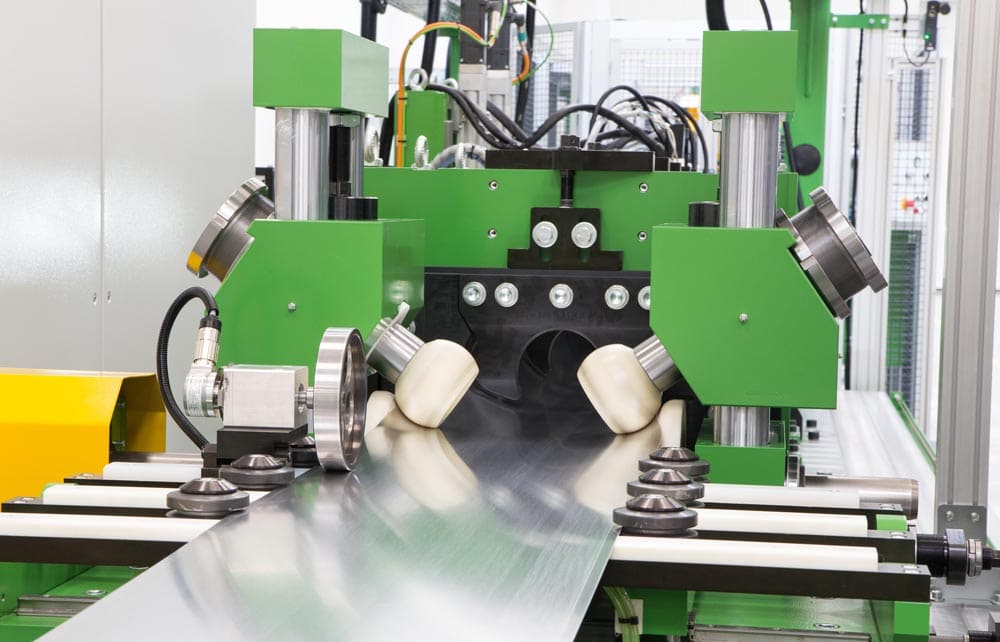

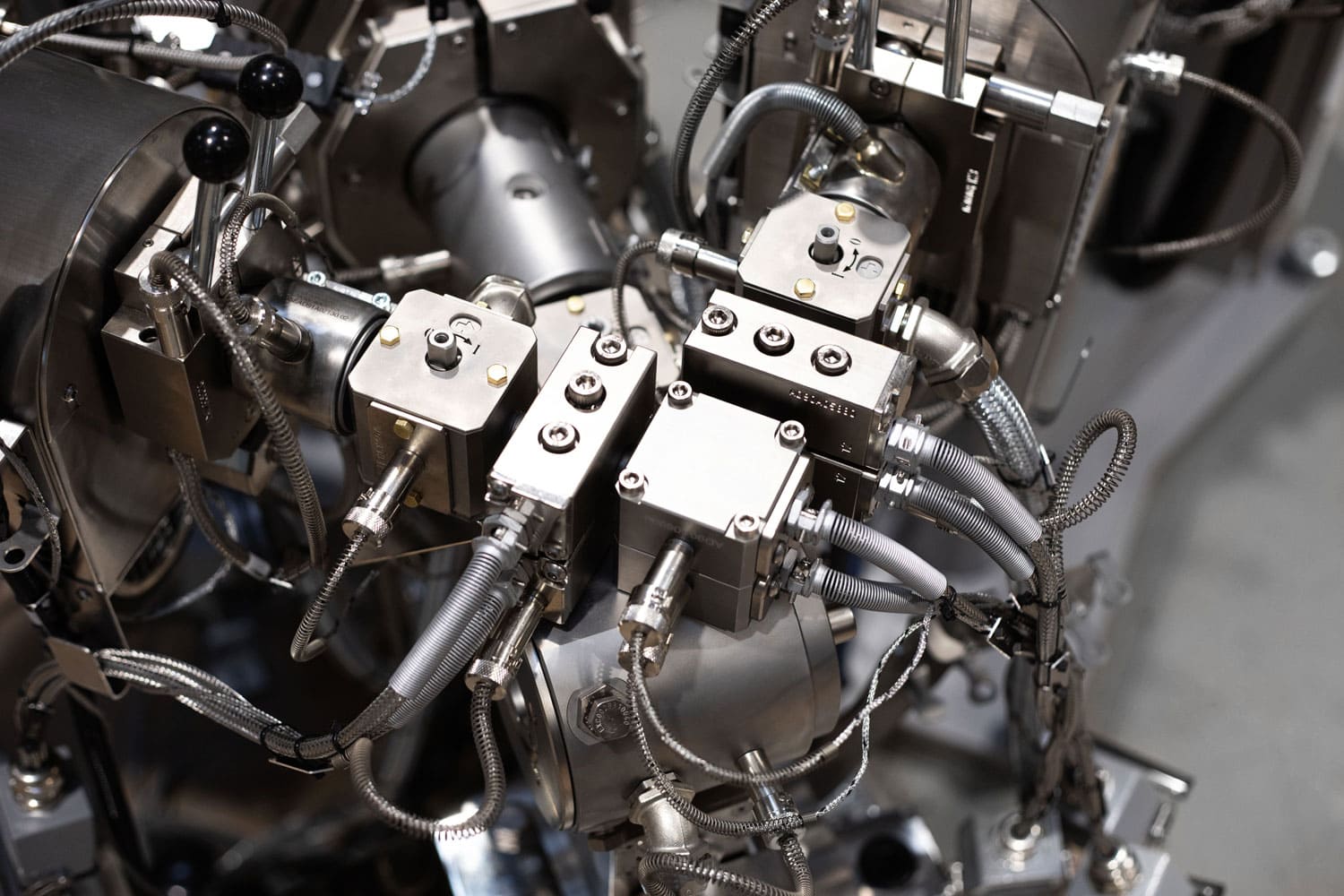

Boosting productivity in magnet wire insulation

Building on its work with high-temp polymers, Rosendahl has developed processes for new materials in magnet wire insulation, such as PEEK, TPI, PPSU, and PFA.

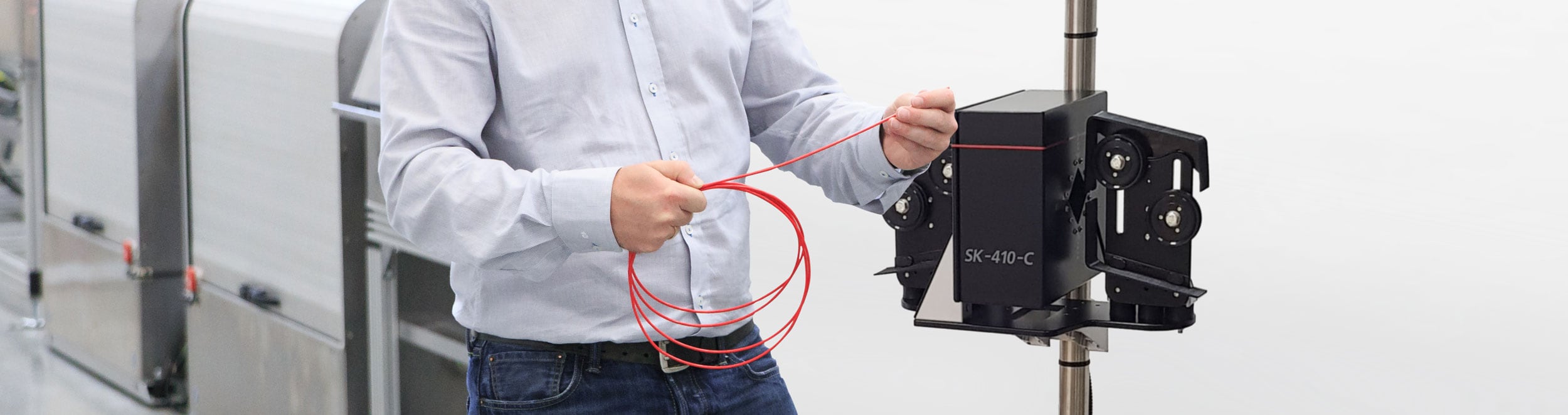

In addition, productivity receives a significant boost thanks to a new inline wall thickness scanner and a fully automated, robot-assisted winder.

communication

What AI needs

As AI technology is now woven into every aspect of our lives. Copper and fiber optic solutions from Rosendahl and Nextrom deliver everything needed for modern data centers and networks: Speed, reliability, and energy efficiency for long- and short-distance connections alike.

Complete manufacturing solutions for data center interconnectivity

From fiber to finished cable: Rosendahl Nextrom provides the complete toolkit for next-generation DCI infrastructure with manufacturing solutions for rollable ribbons, rollable ribbon “super bundles”, and premises cables for rack-level connections. These technologies enable compact, high-fiber-count designs for efficient, high-capacity data center networks.

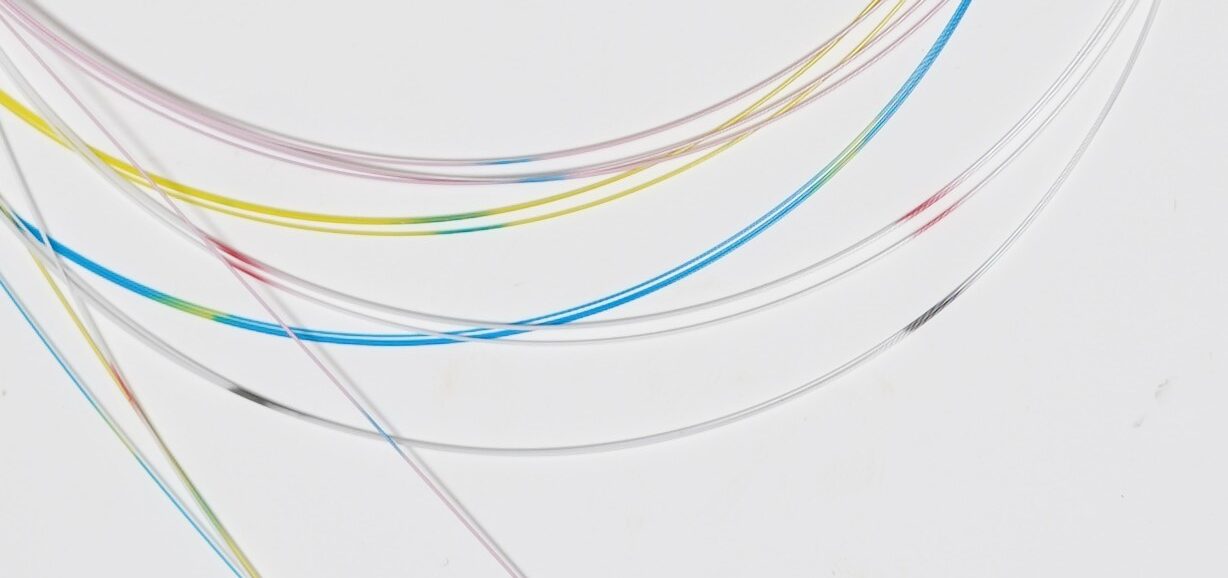

High-Speed Multicolor Ringmarking

Nextrom’s Multicolor Ringmarking ensures high-quality fiber identification with 80+ color combinations and minimal attenuation increase, overcoming limitations of traditional inkjet marking. Its wet-on-wet process delivers sharp rings at up to 1,600 m/min, unlocking new cable concepts and higher fiber counts.

AI and robotics

Next in automation

Rosendahl Nextrom has taken early steps toward integrating humanoid robots into cable manufacturing — offering a glimpse of what’s next in automation.

RIO line control has received major updates, including integrated AI features that finetune precision up to 50 % and reduce start-up scrap by up to 80 %. A major step toward sustainable, high-speed production.

Experience all innovations live in Hall 9, Booth A60.

We are looking forward to your visit!

contact

get in

touch

with us