3 steps to a dry surface at 2,400 m/min

October 17th, 2025

We have modified our proven drying system for automotive wire insulation to meet the demands of higher speeds.

share

Higher productivity for automotive wire production

Proven drying system - now modified for higher speeds

A dry product surface is the foundation for accurate in-line quality control in cable production. To ensure this, our Rosendahl automotive lines use a 3-stage drying process — now adapted for speeds of up to 2,400 m/min.

The process follows 3 steps:

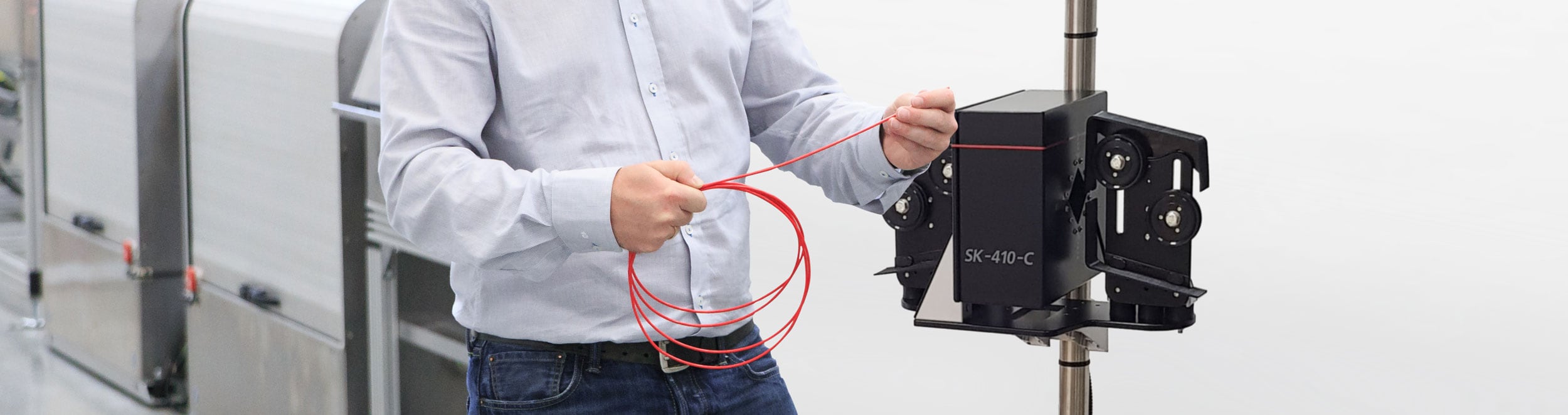

Centrifugal

pre-drying

This first drying unit reduces moisture by around 70–80%, using centrifugal force gently and at low tensile stress. It is maintenance-friendly and does not require changeover.

Superdry air wipe system

In the second step, Rosendahl’s newly developed and automated Superdry system creates a supersonic air flow through its unique air channel design. It removes residual moisture efficiently at high speeds while reducing compressed air consumption by up to 50%.

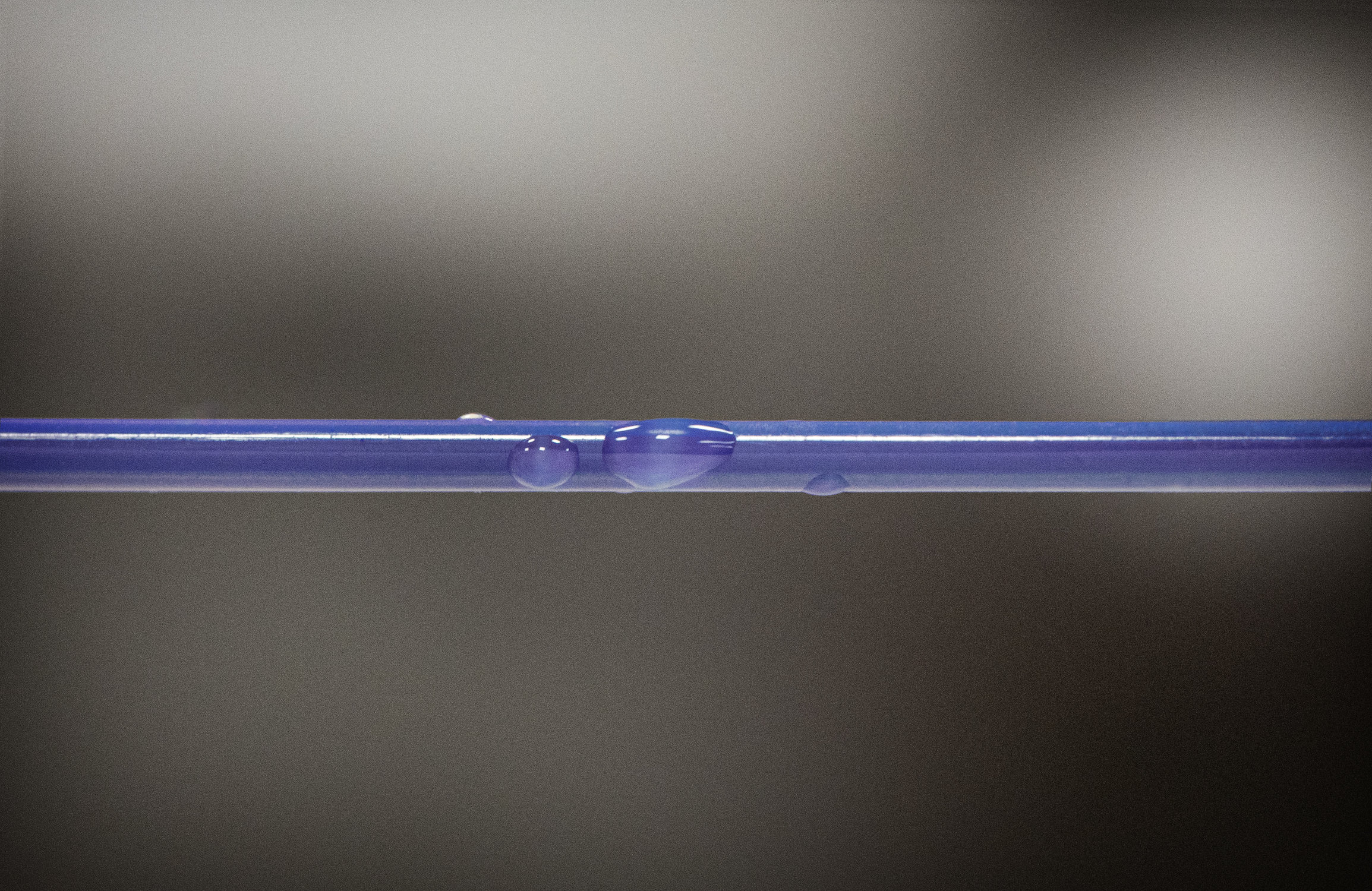

Blowing suction device

In the final step, a blowing suction device removes the last traces of surface moisture, ensuring that no humidity remains on the insulation.

say goodbye to false quality alarms

This 3-stage approach prevents follow-up issues such as false alarms in lump detection or quality deviations caused by residual moisture. It also simplifies handling and saves time in operation.

The new drying system is available for Rosendahl automotive wire insulation lines with RIO line control. And because higher speeds also demand reliable winding, Rosendahl provides matching winding solutions to complete the setup. Tailored to your individual needs.

contact

get in

touch

with us