Putting ghost lumps to rest

October 31st, 2023

Ronex Superdry, our automated cable drying system with supersonic airflow finally puts ghost lumps to rest.

share

Energy-friendly solution for cable drying

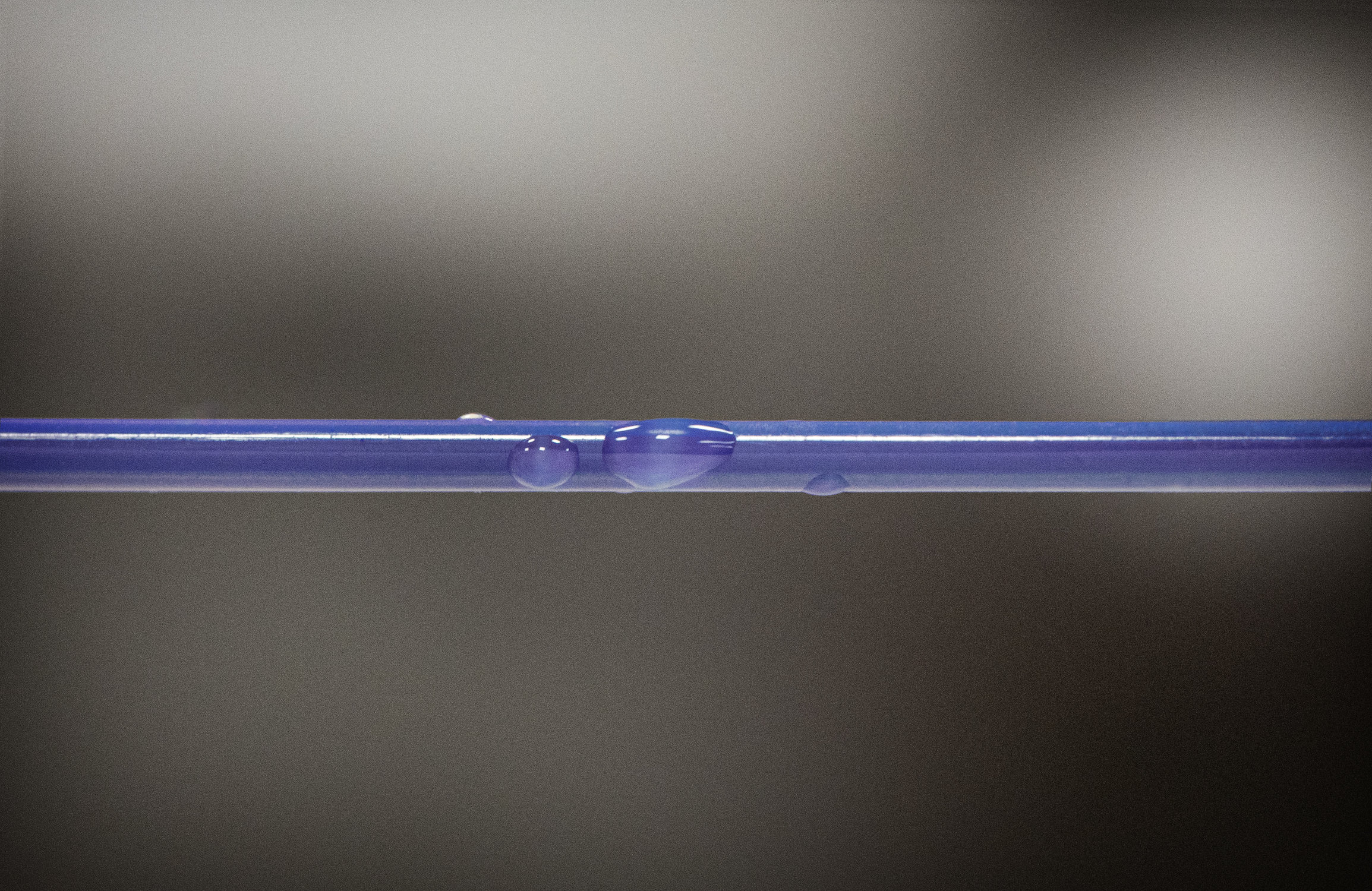

Keeping up with increasing line speeds in cable production can be a problem for conventional drying systems. Bothersome ghost lumps can lead to false quality alarms. Now, Rosendahl Nextrom has developed Ronex Superdry, an automated cable drying system with supersonic air flow, to finally put them to rest.

Unique air channel design

A Superdry nozzle dries reliably at speeds of up to 2,000 m/min where standard nozzles reach their limits.

50% less compressed air

1 Superdry nozzle can replace 3 conventional ones. This reduces the compressed air consumption of the entire drying process drastically.

Automated user-friendly solution

The system closes automatically after a successful startup. This reduces operating time and lowers the risk of product break.

A surface dry product is the basic requirement for reliable inline measurement and quality control later in production. If the product has not dried sufficiently by then, the measuring gauges might detect water artifacts as fake lumps, or so-called ghost lumps. False alarms coming from lump detection cost operators a lot of time and rewinding effort. All for nothing, because the product is in fact flawless, just not dry enough yet. The higher the line speed, the more often conventional drying systems cause this problem. That’s why we made it our mission to develop a drying solution that can easily cope with line speeds of up to 2,000 m/min.

The complete Superdry system is protected from noise and mist. After the successful start-up process, the system closes automatically. This reduces operating time and lowers the risk of product break. Additional features include easy threading and improved stabilization of the cable or tube during the process.

Supersonic airflow

A Superdry nozzle dries reliably at speeds where standard nozzles reach their limits. The secret lies in its unique air channel design. Our team has successfully optimized the air channels to enable airflow at supersonic speed. Water residues no longer stand a chance.

50% less compressed air consumption

Compressed air is one of the most expensive sources of energy in a plant. With its powerful performance, 1 Superdry nozzle can replace 3 conventional ones. The compressed air consumption of the entire drying process can be reduced by up to 50 % (depending on the configuration) – a significant contribution to energy efficiency. Moreover, it is highly wear resistant.

Suitable for your production line?

If you have any questions about this innovation for high-speed production for automotive and fiber optic cables, get in touch with us!

you may also like

contact

get in

touch

with us