How to prepare your factory for efficient line commissioning

January 22nd, 2026

Good preparation is key to a smooth and efficient commissioning process. Here’s how you can support our team and speed up your start.

share

Our common goal:

smooth on-site commissioning so that you can start your production as soon as possible.

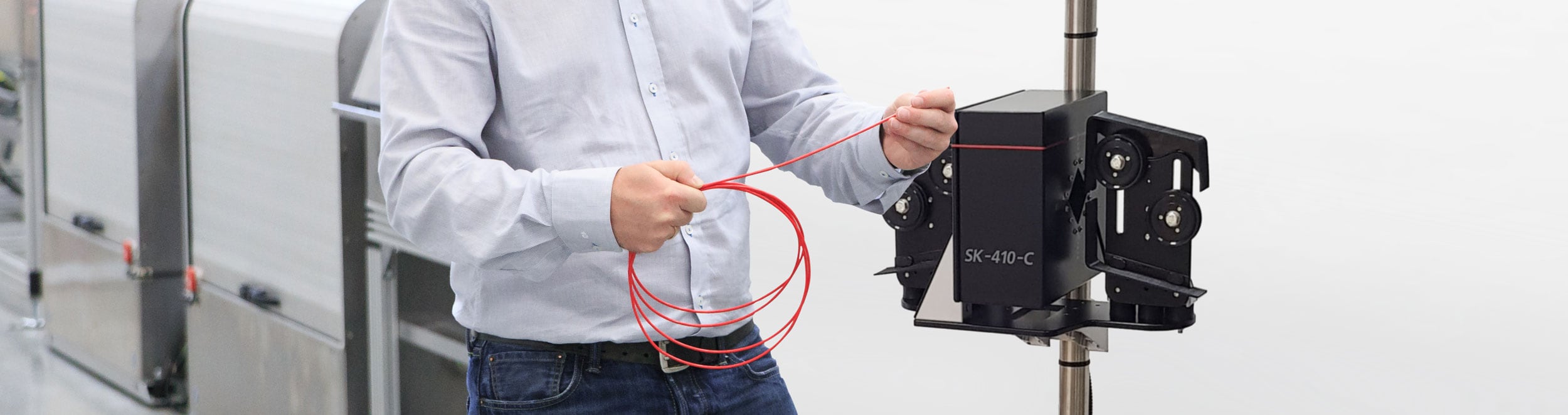

Cable production lines vary a lot, they are complex setups, often customized. And, of course, not everything that happens on site can be planned or predicted.

Factors that influence commissioning duration

- Complexity and size of your line (number of machines, different line modes).

- Availability of materials.

- Presence of third-party machines and how well they integrate.

- Quality of provided tools and materials.

- Availability of staff on site.

- Missing or defective components.

Good preparation is key

Here’s how you can support our team for a smooth and efficient commissioning process and speed up your start.

Before we arrive, make sure you:

- Provide power, compressed air, and water supply connections.

- Prepare evenly leveled floors. Pay attention to floor height and soil bearing capacity.

- Don’t bolt the processing unit (extruder and crosshead) to the floor yet. Our engineers need some flexibility for fine-tuning the alignment.

- Don’t run cable trays or channels beneath machines or too close to moving parts.

You’ll also need to provide:

- Scrap material and empty reels for rewinding and trial runs.

- Access to your LAN and ERP system (if integration is planned).

- Technical staff (electricians, mechanics, trainees) on site.

You will receive a checklist

Please refer to the project management checklist and pre-documentation we provide. These include everything you need to have ready before commissioning begins.

contact

get in

touch

with us