Equipment for fiber optic cable production

unique stranding technology for long production runs

Our efficient SZ stranding technology is designed for manufacturing fiber optic cables for a wide range of indoor and outdoor applications. It ensures low stranding tension fluctuations, and consistent binding tension.

Thanks to our ultra high-speed strander and low-tension crossbinder, our SZ stranding process sets a new standard in productivity:

- High production speeds

- Long batch runs

- Minimized setup and downtime

Your benefits

gentle processing

large batch sizes

high productivity

50 km of nonstop stranding

By using longer batch sizes, you can boost performance by up to 20% compared to 25 km batches, while further reducing your scrap rate.

shortest reversal length on the market

Together, our low-tension crossbinder and ultra high-speed strander achieve the market’s shortest reversal length. Ensuring uniform flexibility along the entire length of the SZ-stranded cable and allowing it to bend, twist, or move without breaking or loosing its structural integrity.

Line highlights

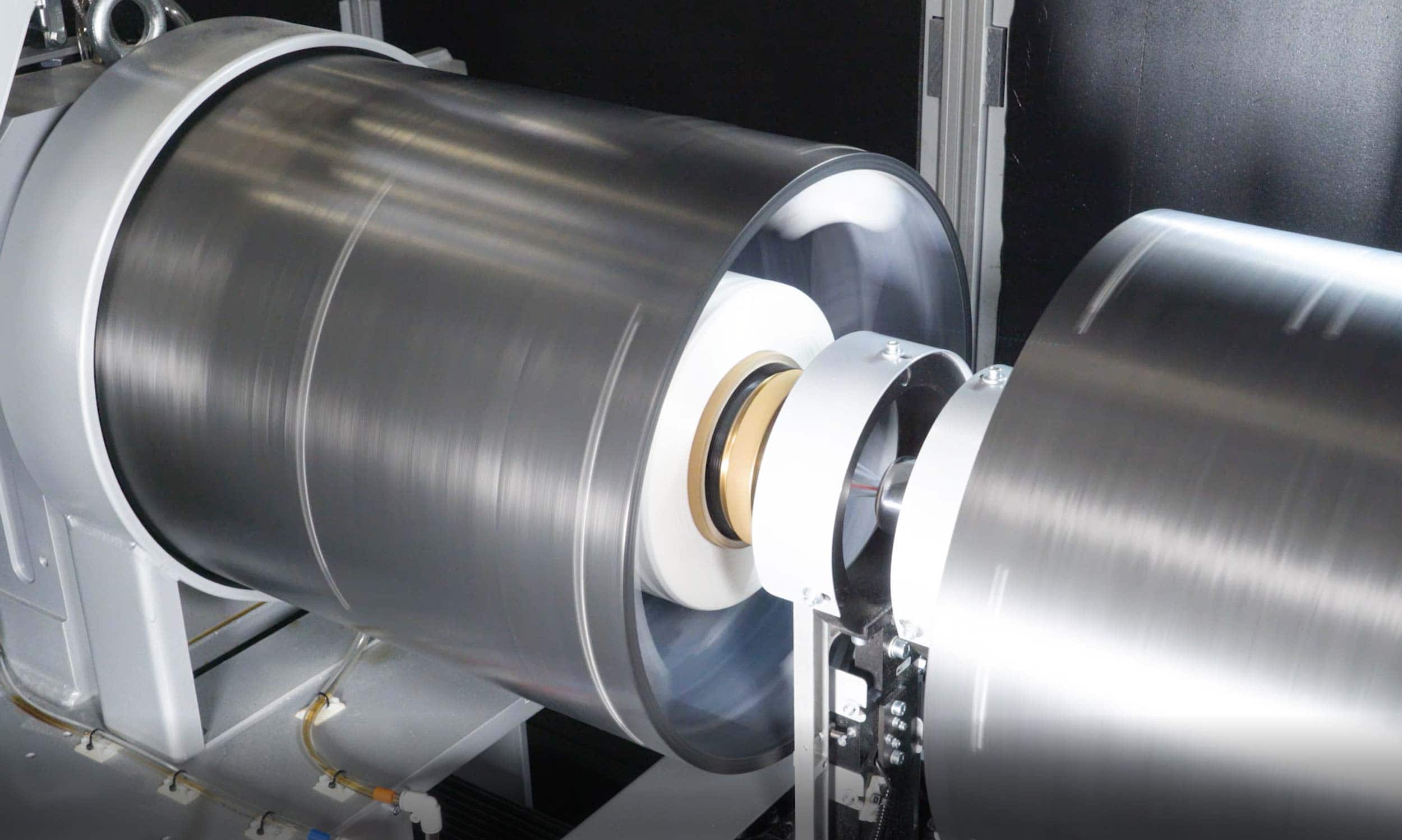

DTSZ

Ultra high-speed strander

This ultra high-speed strander has been engineered for short reversal times. Its high-dynamic drive system ensures precise lay reversals and reaches speeds of up to 2,500 rpm.

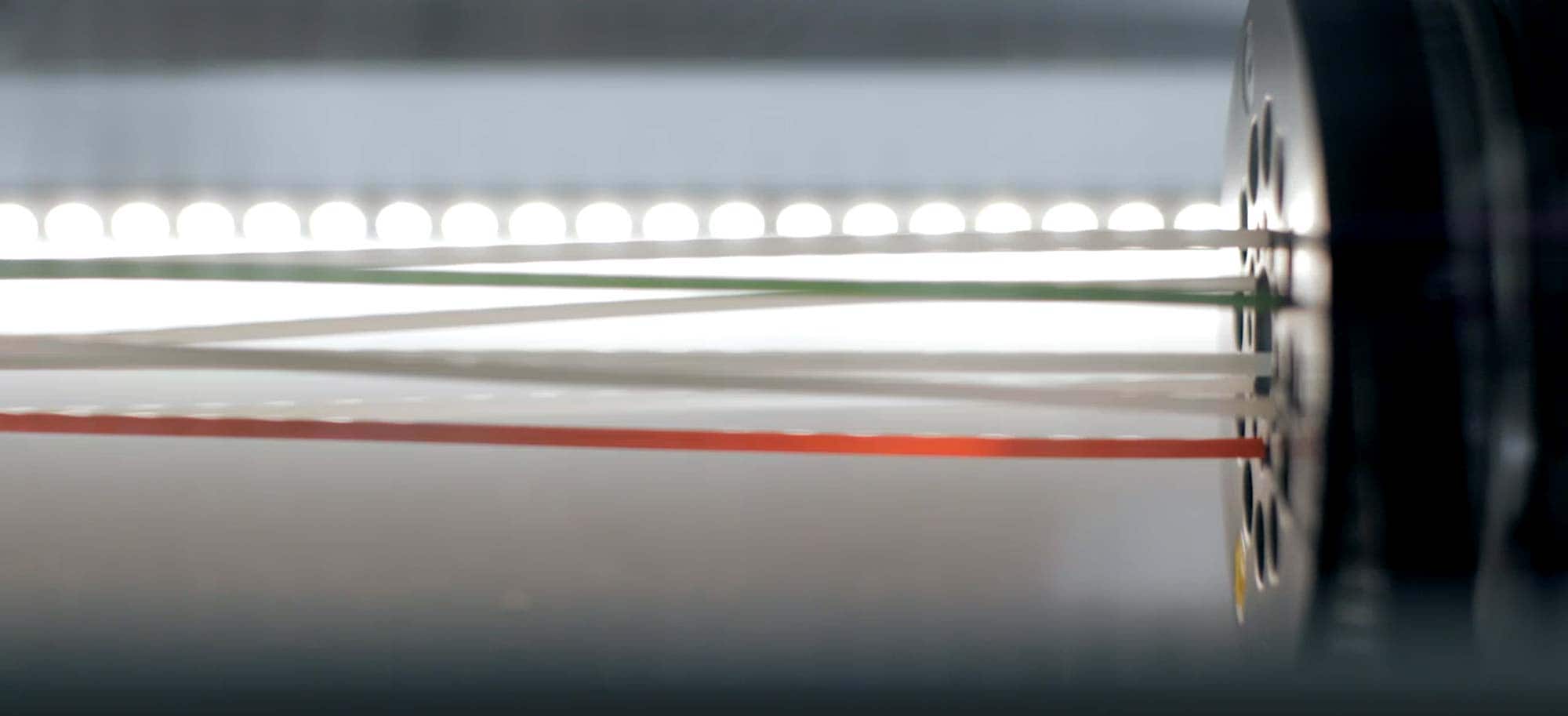

ROBI

Low-tension crossbinder

ROBI is our low-tension crossbinder, designed to handle your FOC product with care at up to 4,500 rpm, maintaining a constant yarn tension below 2 Newtons.

RL-V technical data

| Processing data | Loose tube | Ribbon tube |

|---|---|---|

| Structural speed | 200 m/min | 200 m/min |

| Elements | up to 24 | up to 12 (depending on tube diameter) |

| Diameter of elements | 1.0 - 4.0. mm | up to 9.0 mm |

| Diameter range | 3 -25 mm | 15 - 35 mm |

| Layers | single and dual layer stranding | single layer stranding |

contact

get in

touch

with us