The next generation of extruder screws

October 16th, 2024

Boost your output by up to 40% with the latest screw and feeding zone design.

share

extrusion technology

What the latest screw and feeding zone design are capable of

The extrusion process is subject to constant change:

- Cable products are getting smaller.

- Wall thicknesses are getting thinner.

- Materials are being substituted.

- Production speeds are increasing.

- The process window for the extrusion process is getting narrower.

To deal with these and future demands, our R&D team has enhanced our extruder screws and the corresponding feeding zones in extensive laboratory and field tests.

The results speak for themselves:

Up to 40% higher throughput

Improved melting performance

Improved mixing quality and melt homogeneity

Less wear and tear

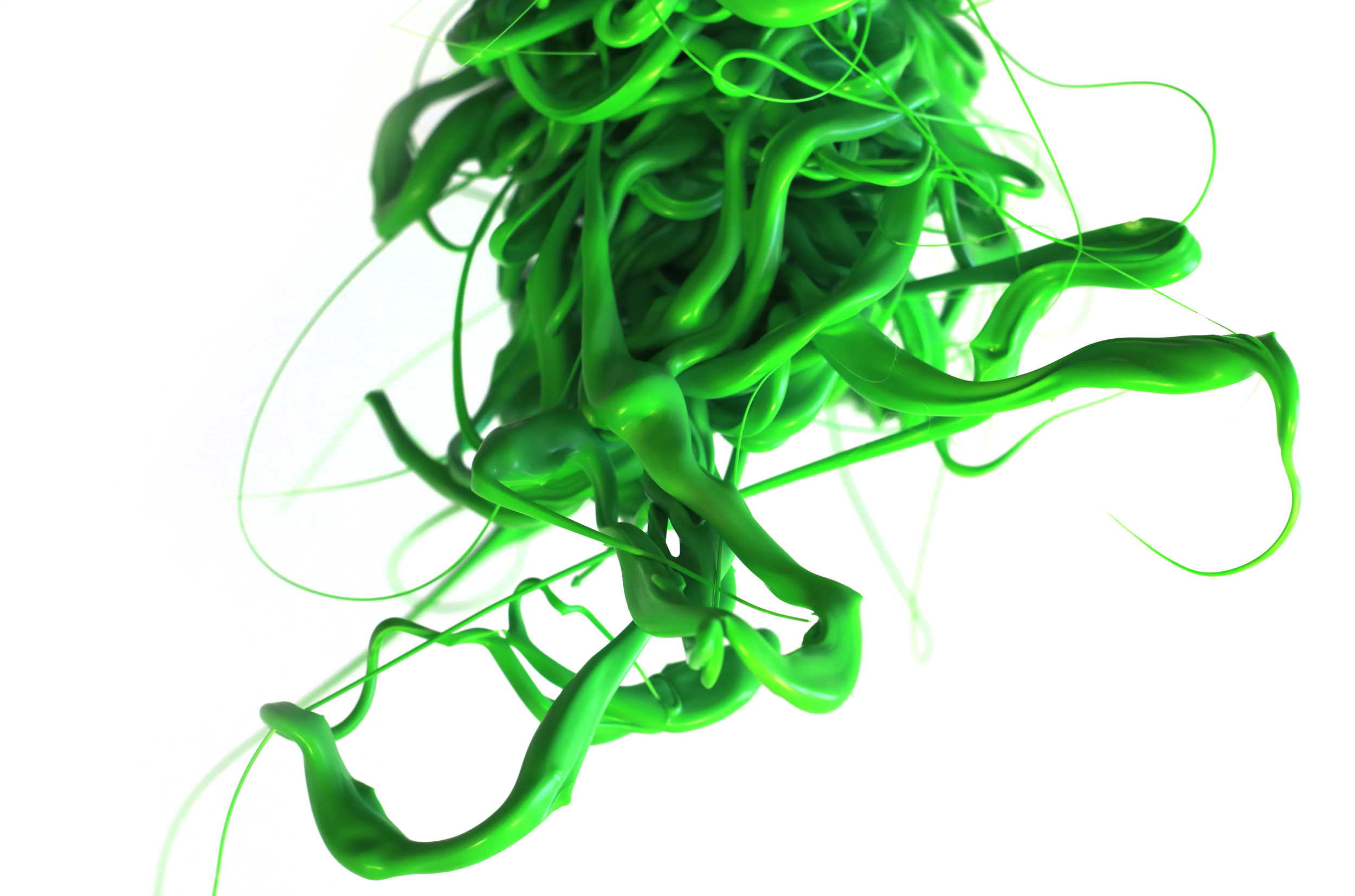

Dried polymer layers peeled from the extruder screw to analyze the mixing quality.

your success is our passion

Screw and feeding zone – a powerful duo

Bringing the extruder screws to that new level of excellence, is the result of rigorous testing and iterative design adjustments with the support of the latest simulation software, combined with field tests at different customers’ sites. The focus of the R&D work was to refine the interaction between the extruder screw and the feeding zone. After all, the synergy between those two parts is key for maintaining a homogeneous polymer mass over the entire extrusion process.

The team itself is impressed with the results achievable.

you may also like

contact

get in

touch

with us