our new co-extrusion crosshead

September 02nd, 2019

The most common coating variant for LV power cables, the "tandem extrusion", is increasingly being replaced by so-called "co-extrusion".

share

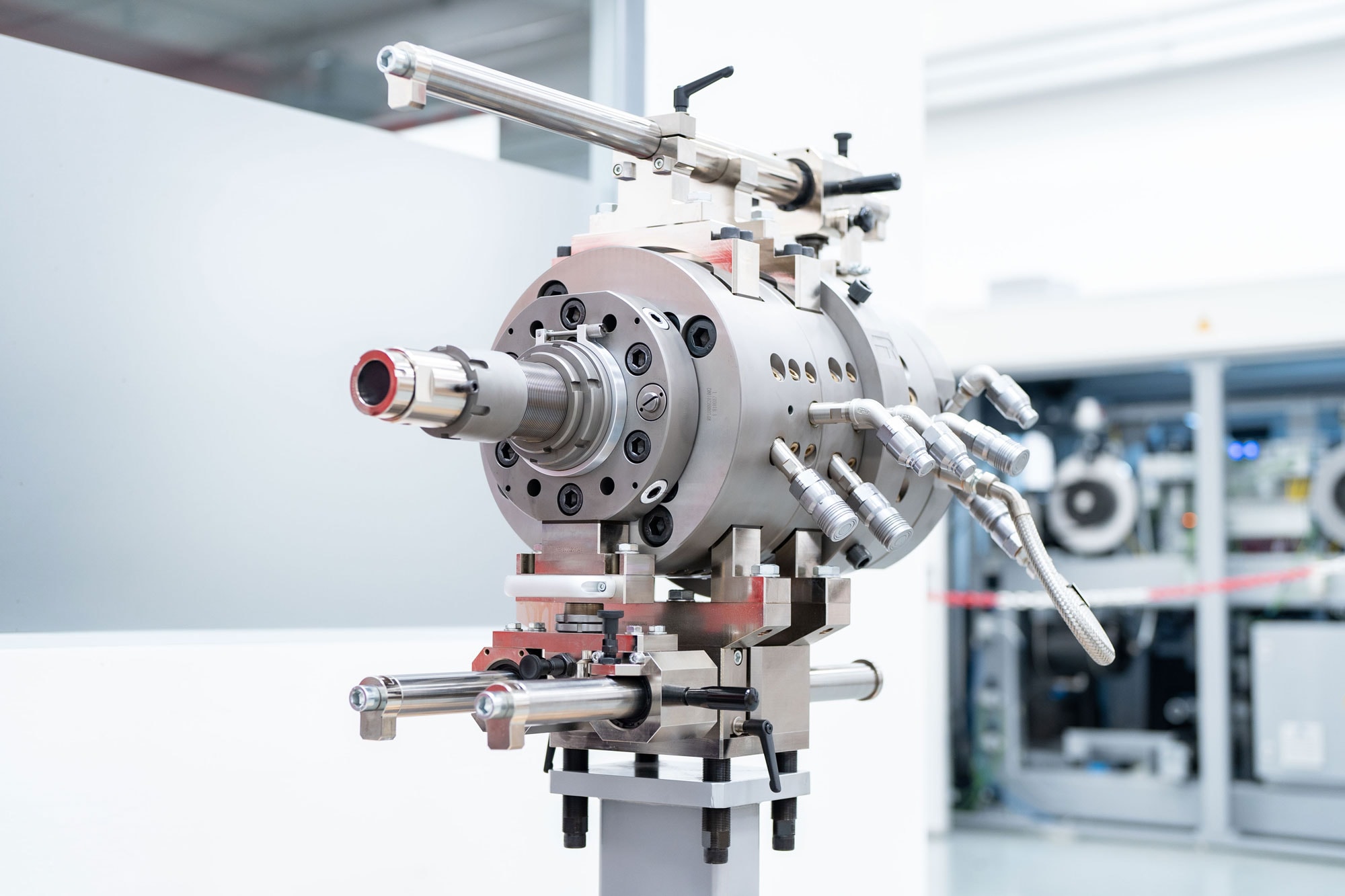

crosshead RX 40 MB 2.1.I

Co-extrusion is getting more important because it is more efficient and thus more cost-effective.

Another reason is, that it is becoming inevitable due to the many different extrusion materials.

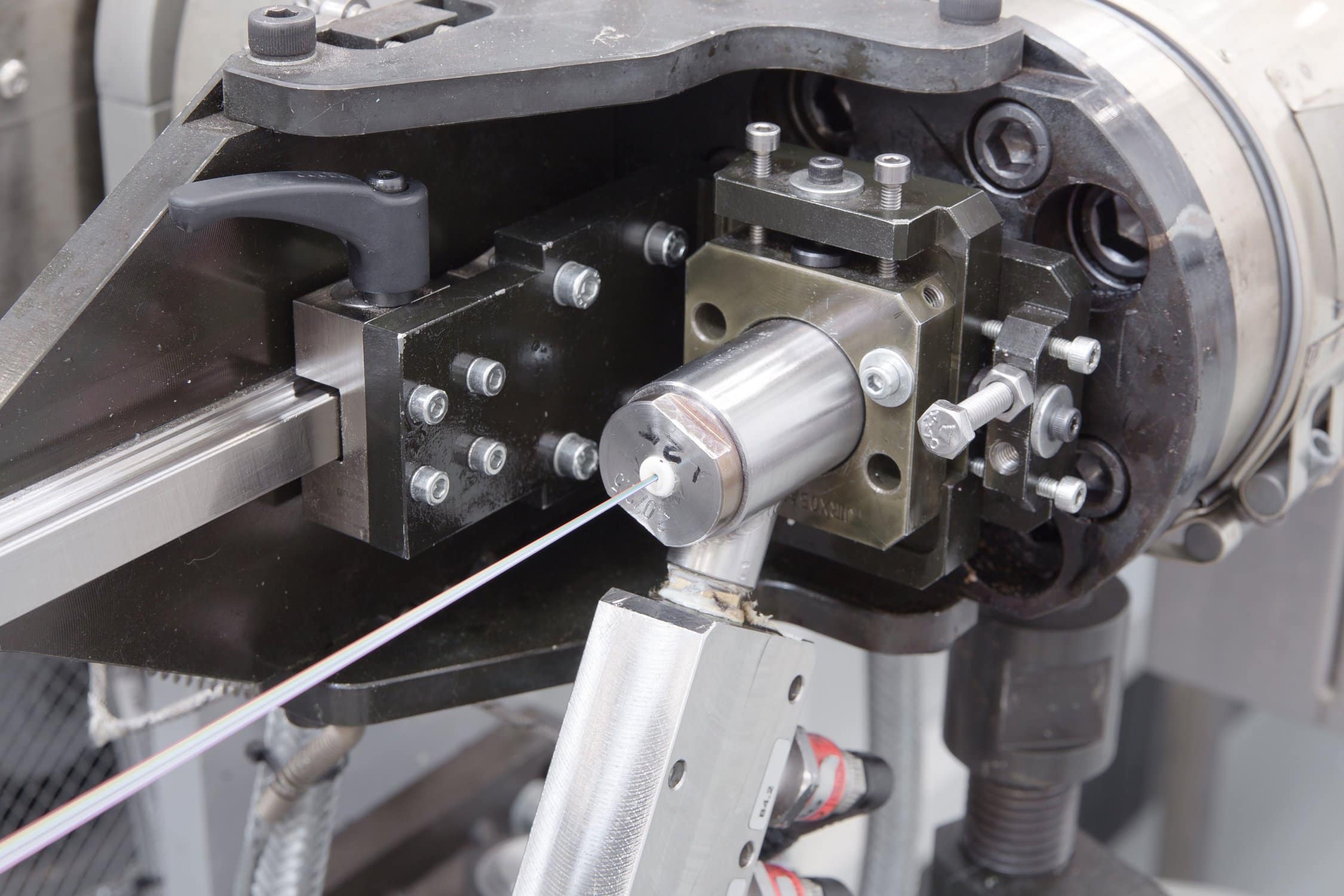

Our new crosshead RX 40 MB 2.1.I was specially developed for these requirements. It enables the co-extrusion of different material combinations, such as EPDM with PVC. And all with only one crosshead!

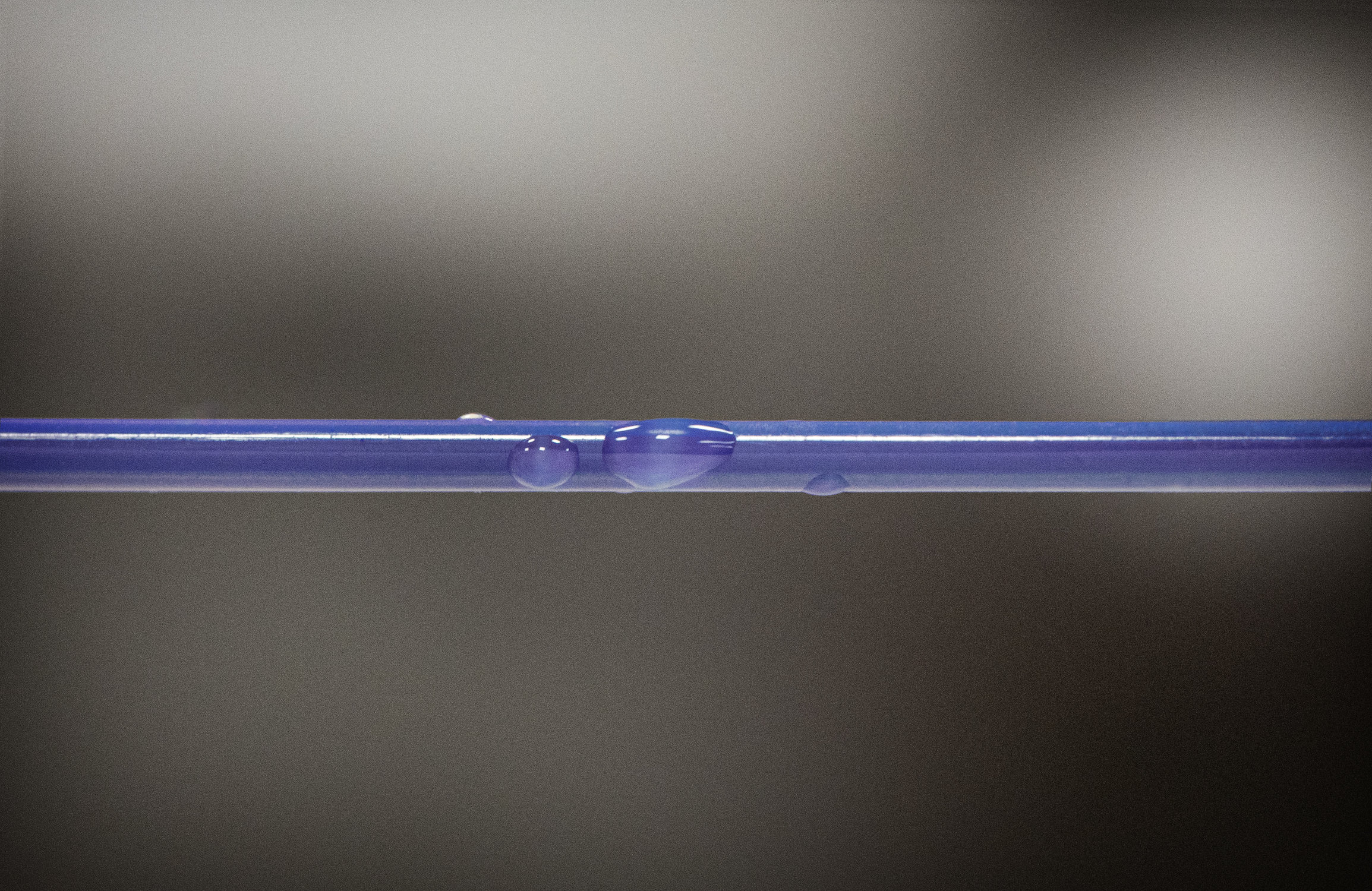

Cables, especially for the field of building cabling, have ever thinner and optimized wall thicknesses. These products require a high degree of precision in their manufacturing process.

During the development of this new crosshead, we made special efforts to ensure that commercially available products can be processed from a diameter of only 3 mm.

The head is also liquid-tempered, which means that, if necessary, very low plastic melt temperatures can be processed. Due to thermally separated material flows, materials with different melt temperatures can be extruded. These properties are particularly important for the production of flame-retardant materials, such as LSOH. Another advantage are the separately heated head zones. As a result, the required production temperature can be controlled even better and constantly monitored during production. This achieves stable process conditions for the entire production time, even with changing processing temperatures.

easier to use

due to co-extrusion

material saving

thanks to the possible processing of thinner filler wall thicknesses.

preventive

by eliminating an additional intermediate cooling path and cable drying

product information

-

core diameter 0 - 30 mm

-

layer types Double Layer Double Layer + Skin or Stripe

-

materials PE, PVC, EPDM, Flame-Retardant Polymers

you may also like

contact

get in

touch

with us