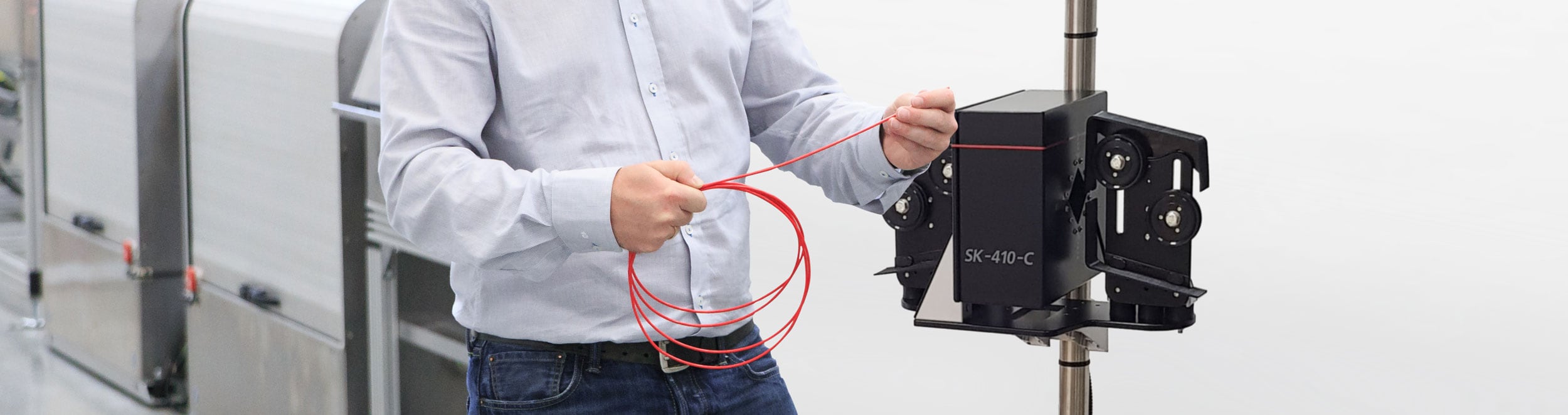

cable production

Scrap is an unavoidable byproduct of the cable manufacturing process. The good news: it can be minimized and we have many smart options available to help with that.

Scrap costs time and money, and creates waste that needs to be disposed of. These efforts can be minimized if less scrap is produced from the start.

how to save scrap

It all starts with proper organization

Planning production runs smartly is the first step in preventing scrap in cable production. Cleverly organizing the product sequence and minimizing the number of changeovers between different production runs can make a significant difference.

Equally important is the regular maintenance of equipment and machinery, which prevents breakdowns and defects in produced cables. Worn out components should be replaced promptly to avoid generating scrap. Additionally, well-trained operators reduce mistakes in production and improve efficiency, leading to even less scrap.

Quick start-ups and production stops

The biggest portion of scrap is generated during the start-up and shutdown of a system. Why is that? When the production line is started, it takes some time for the machines to reach optimal operating conditions. The raw materials processed during that time are considered scrap. Similarly, when the production line is stopped, any leftover materials in the machinery may need to be scrapped.

That’s why it’s essential to design the entire production line with the smallest footprint possible. When the distance from pay-off to take-up is shorter, less cable length is required in the line, reducing scrap generated with each production run.

Rosendahl Nextrom machines are optimized for very fast start-up, allowing production to stabilize quickly. Extensive process know-how and precision engineering go into this. Well-coordinated machines and processes hit the mark from the start, ensuring rapid system stabilization.

Process stops are also optimized. The main focus here lies on conserving materials and reusing them in subsequent production runs. In general, both start-up and shutdown scrap can be minimized by reducing the number of start-ups. Depending on the line type, you can choose continuous production or implement stop-and-go processes to help keep material scrap low.

Stable manufacturing conditions

When the line is running, it is important to keep the process stable to produce consistent quality and avoid failure rates. A stable process has another major advantage: tighter tolerances can be set, and the wall thickness can be thinner – another factor for savings.

A basic but important thing to reduce vibrations on the line is to use stabilization rollers for exact product guidance.

Under optimal conditions, some production lines can run uninterrupted for a long time, provided they are equipped for continuous production. This requires fully automatic dual reelers or winders with accumulators, and other necessary equipment. A line can’t run indefinitely, though. It needs servicing, such as cleaning certain parts or regularly changing the extrusion screens, to maintain high product quality.

Modern line control systems, such as RIO, offer inline measuring gauges and real-time quality monitoring of both the process and product quality. As soon as the quality criteria are not met, production must stop. Every second counts, especially at speeds of 2,000 m/min or higher.

save scrap. save money

Double-digit scrap savings are achievable, cutting costs and reducing environmental impact, when these factors are in place:

Proper planning

Quick start-ups

Stable production

Quick shutdowns

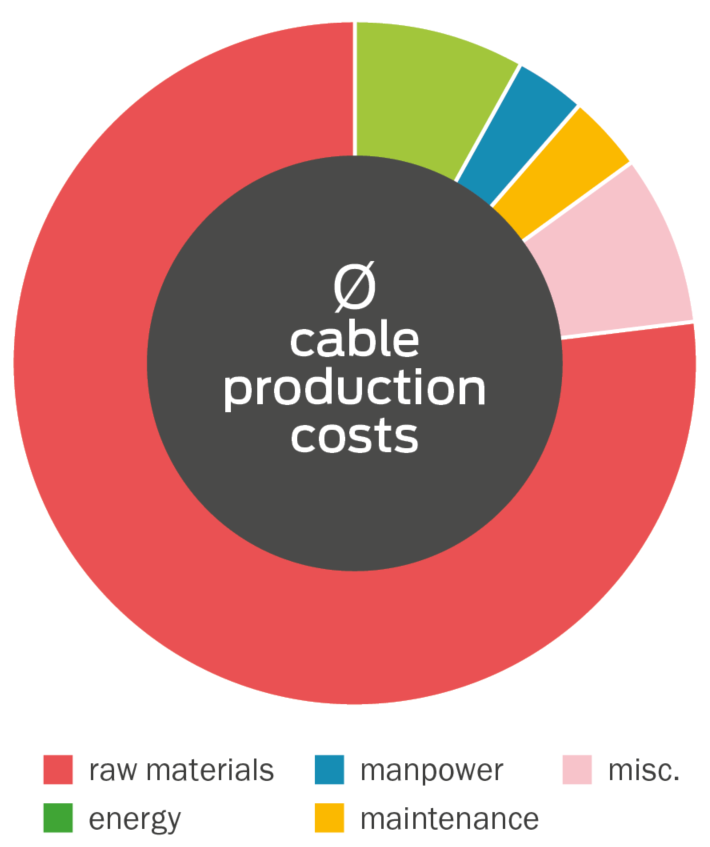

cable production costs

Does the cost breakdown of your cable production look similar to this?

There lies big potential for cost and CO2 savings in the efficient use of raw materials. This is especially true for expensive materials like copper, optical fibers, or high-performance plastics which are difficult to recycle, especially if they are mixed.

Get in touch to get more information about our latest scrap saving production solutions.

contact

get in

touch

with us