Goodbye jelly needle, hello jelly die!

April 17th, 2023

After conducting rigorous testing under real-world conditions, Rosendahl is replacing its jelly needle with a new die system.

share

loose tube production / outdoor applications

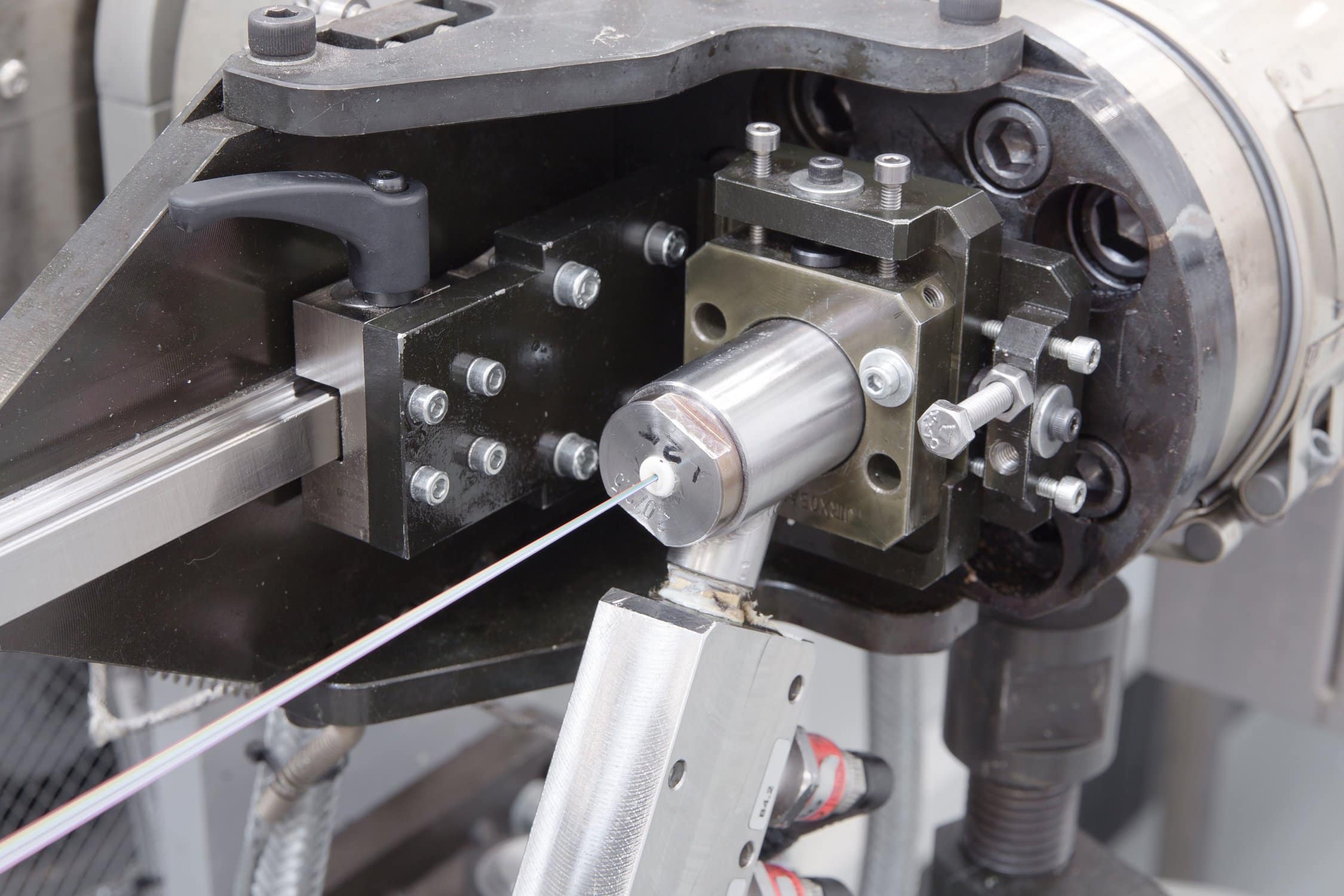

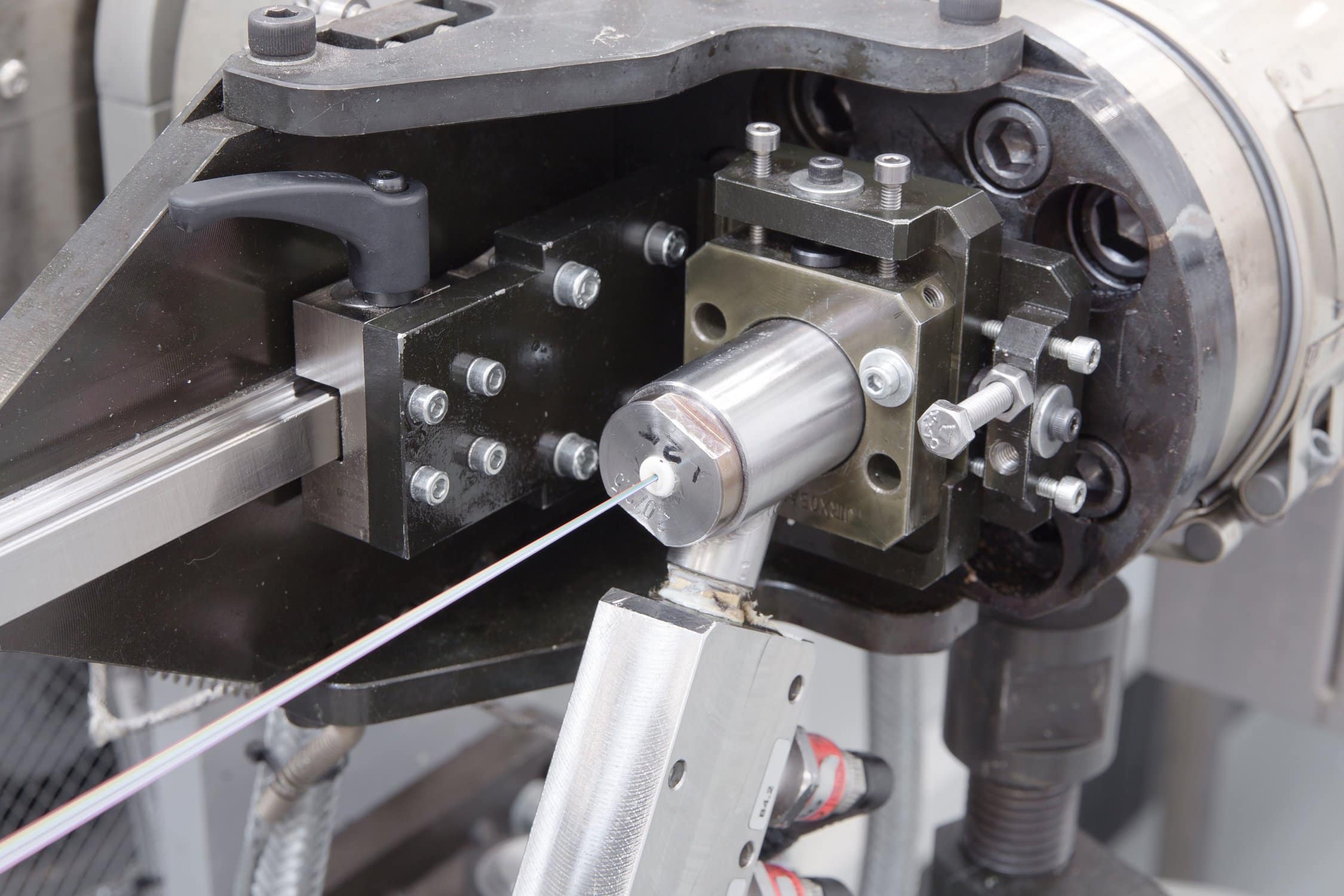

Fiber optical cables for outdoor applications must be protected from water penetration. One way to achieve that is to fill the loose tubes with jelly. Until recently, Rosendahl Nextrom used a needle system in their jelly application head. It is now being replaced by a new die system that offers numerous benefits to both the production process and the quality of the final product. By making this small, yet significant adjustment to the process of jelly filling, wer are taking the production of loose tubes to a new level of excellence.

Successful lab and field tests

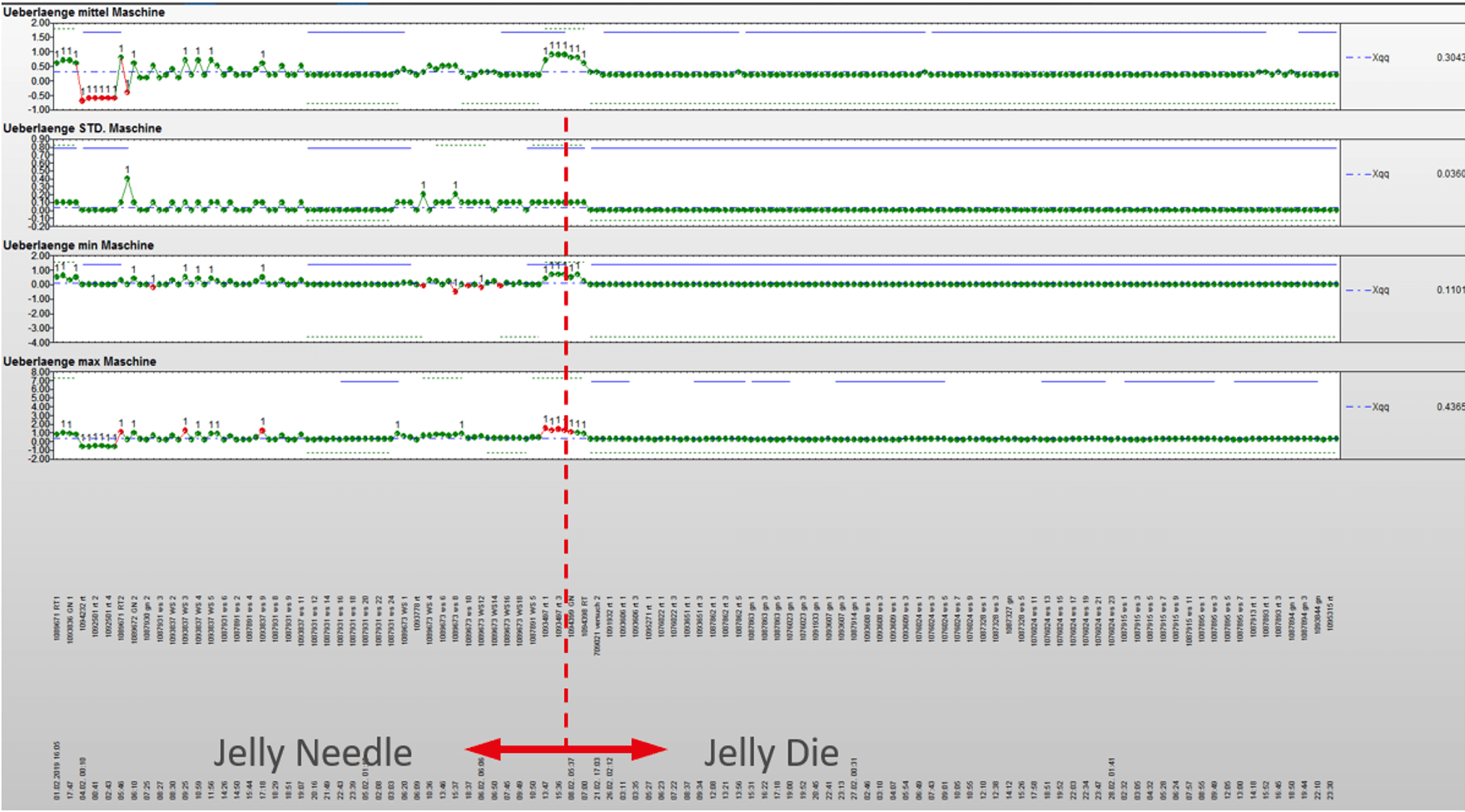

Extensive tests at Rosendahl’s laboratory plant have already shown an optimized jelly flow and better process stability with the new jelly die system.

In addition, to prove its reliability in the field, the new jelly-filling die system has been tested together with a customer under real production conditions. The before/after speaks for itself: there are significantly fewer EFL variations. Why is that? Within the jelly die, the fiber bundle experiences fewer turbulances due to the optimized design of the die system.

Minimal maintenance

If you’ve had to regularly change a jelly needle in the past, there is good news for you: The die is much more compact and cannot bend and wear out like a needle. That makes handling much easier. Less maintenance is required.

you may also like

contact

get in

touch

with us