Why AGM?

Ron Miksiewicz shares in an interview why east penn chooses AGM technology for reliability, performance, and future-ready energy solutions.

Can you briefly introduce your history with AGM

battery production?

Ron: We started developing sealed valve-regulated AGM batteries almost 40 years ago and shortly thereafter began low volume production in our maintenance building in an area we called “the pilot plant”.

Most of these batteries were produced for the wheelchair/electric mobility and Marine market, where flooded batteries had been dominant

for many years, but a new trend to improve on product performance/cycle life and reduced maintenance was beginning. In the early stages, we learned a lot about what worked and didn’t work so well. We then took what we learned from those early days and just kept building on it. Our engineering team, under the guidance of Bob Flicker, learned about this new technology through our industry partnerships/relationship, attending industry technical conferences and working closely with industry material and equipment suppliers to enhance our capabilities. We also brought on new talent to increase our know-how and abilities. All these things, combined with a “Can Do” attitude and a great leadership team focused on product quality and market penetration, allowed us to grow this business across most product lines.

How has your AGM production evolved over the past few years?

Ron: With recent industry growth and market opportunities for AGM, we have expanded our AGM production significantly over the past several years. Without getting too specific, I would say we are keeping pace with published industry data for AGM

valve-regulated battery market penetration and sales.

Maybe the best way to elaborate on this would be to say that 15 years ago, we had one factory that produced all the AGM/Gel valve-regulated batteries we sold. Today, we have multiple factories that produce AGM batteries & it has become a production norm with many of our processes being integrated to allow for both AGM and flooded production to co-exist. As our customer needs have changed, flexibility in manufacturing has become extremely important to us.

It is important

to remain diligent

in cost optimization

efforts and to improve

efficiency and

product quality.Ron Miksiewicz

Sr. VP Mfg. Support Services

What are the biggest changes you’re seeing in market demand for AGM batteries?

Ron: In the USA we are seeing an increased demand from the aftermarket. Many OEM’s/automakers converted to AGM several years ago.

These batteries are now in their 1st and even 2nd replacement cycles. Some OEMs used two AGM batteries to handle their vehicles electrical requirements, so the growth in this area has been significant. Of course, our Reserve Power AGM products (UPS, Stationary, telecom, etc.) have been in use now for 5, 10 and even 20 years and we are seeing similar trends including new battery systems for 5/6G. Applications for Pb AGM batteries continues to grow, and we are positioned well to meet the market demands.

The main campus in Lyon Station, PA.

AGMs role on the market

Why do you think manufacturers are moving toward AGM rather than traditional flooded batteries?

Ron: Our customers want them. Beyond that, these products have matured over the years. The industry has adopted well, with new materials, chemistry, and manufacturing capabilities. There are so many things we have all learned as an industry. In the early days of AGM, inconsistent quality and high cost hampered its growth.

Today there is a more robust and extensive supplier base than ever before, which has developed sophisticated processes and equipment to improve product consistency. As an example, If you read the most recent “Failure Mode Study” by BCI 2025, you’ll see that AGM battery life is longer than its flooded counterpart, although some of the extended life may be attributed to the location of the battery in the vehicle.

From a manufacturing standpoint, what makes AGM battery production different or more challenging than traditional lead-acid battery assembly?

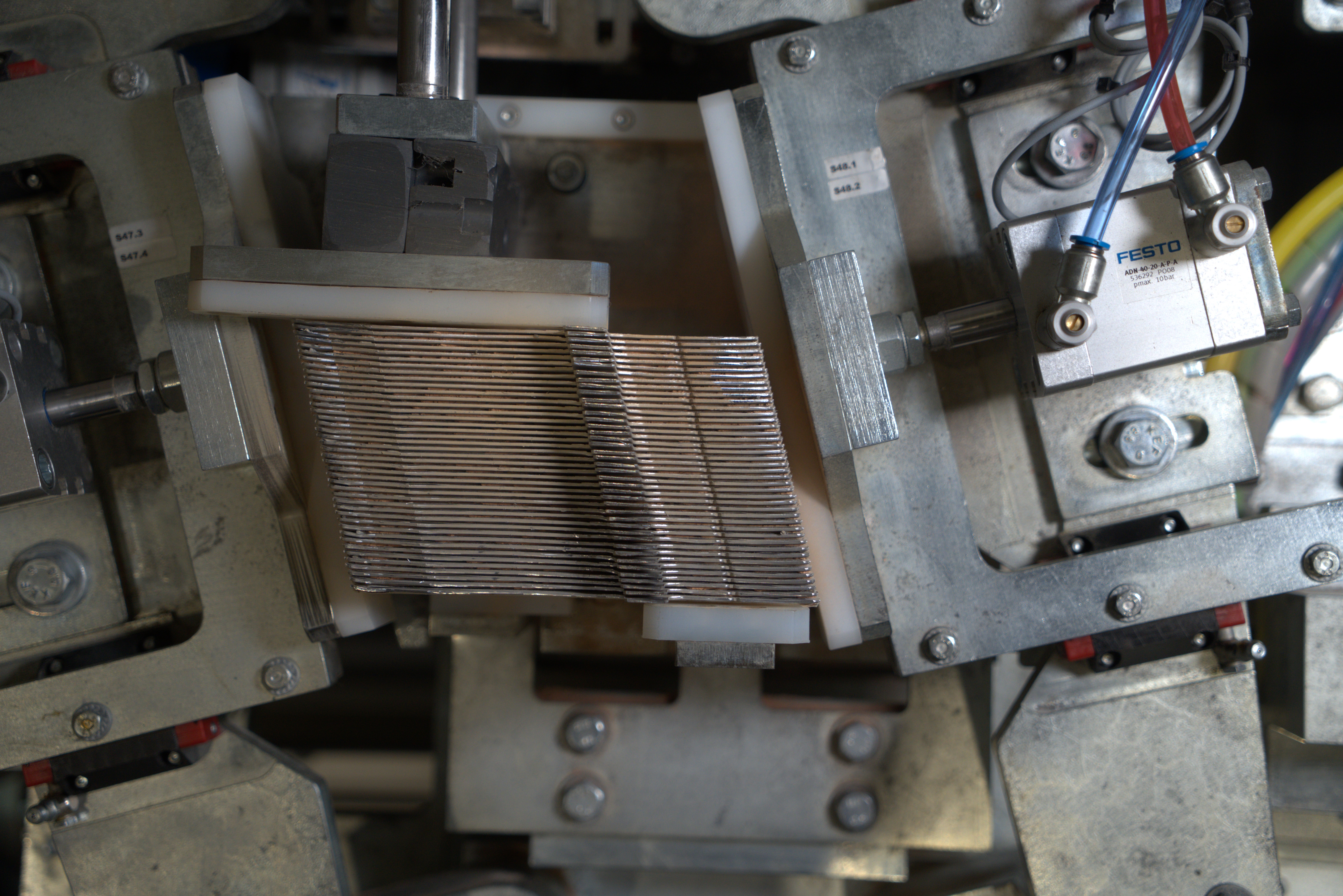

Ron: The materials and the precision required. We have to control the process to be more precise in every aspect. The cells are precisely compressed. Plate thickness, paste weights, acid volumes, final weight, etc.

These attributes are increasingly more impor tant in AGM then in flooded. AGM is considered an advanced Pb battery and quality expectations from our customers are at their highest with these batteries.

What are the most critical factors in maintaining quality and consistency when producing AGM batteries?

Ron: Materials, components, and equipment need to be at their highest quality and performance levels in order to produce advanced AGM batteries. The machinery needs to be set up precisely and maintained properly. Machine operators need to

be trained at the highest level and take ownership of their equipment and the quality they produce.

We are lucky to great people at East Penn and have machinery companies like BM-Rosendahl who understand our requirements and supply us with the very best equipment to meet our goals.

BM-Rosendahl

was willing to help us

out by designing

something new

to help meet our

requirements and

production goals.

We recently introduced the new stack-breaker unit for gently separating pasted plates before enveloping. How does this technology impact the efficiency or quality of your enveloping process?

Ron: Albeit new, the stack-breaker will have the biggest impact to our BMR wrapper stacker machine operators. Today these operators need to manually manipulate pasted plate stacks, prior to placing them into the machine plate feeder tracks.

This new process will eliminate this part of the job. Machine operators will spend less time handling lead plates which allows them more time to keep the machine running efficiently with fewer stoppages.

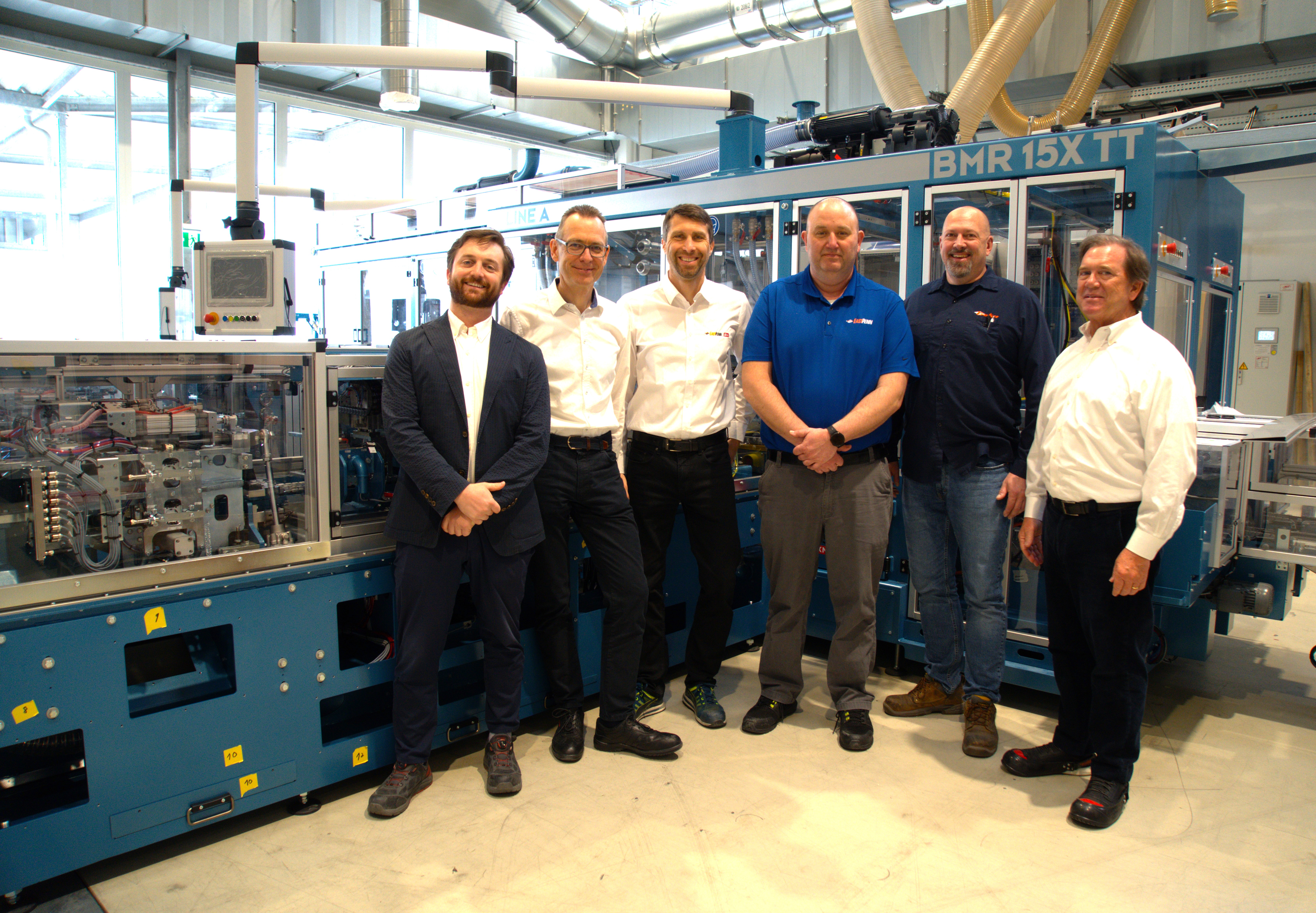

from left to right: Christopher Glascock jr, Richard Jonach, Mario Semmler, Kevin Rutch, Derek Knerr, Christopher Glascock sr.

scalability and automation

Do you see this kind of innovation making a meaningful difference in future production scalability or automation?

Ron: Once you start to automate plate stack breaking, I can easily see the next steps in automation following suite. Becoming more efficient, making the job safer and easier for people is our goal. Of course, we will need to upskill our work force to better understand and work along with future automation. These are exciting times!

What do you see as the biggest challenges – and opportunities – for AGM battery production in the next 5–10 years?

Ron: There’s a lot of talk about AGM and its growth in the USA. Earlier I mentioned, OEM’s continuing to use and demand high quality AGM batteries for their new and replacement vehicles. The aftermarket (retailers, car parts stores, etc.) sees this as an opportunity, so this will continue to have a big influence on AGM growth and sales.

One challenge to the industry and our suppliers is keeping pace with the growth in AGM and being flexible enough to meet the demands of both flooded and AGM. The other challenge, for some, will be the investment in AGM equipment and required manufacturing changes. AGM is similar to flooded, but it’s different enough to require new equipment, advanced training and more precise processing and attention to the details. We will need to further automate our factories to meet these challenges.

Materials, components,

and equipment need to be

at their highest quality

and performance levels.

How do you see the role of automation and equipment suppliers evolving in response to these industry changes?

Ron: We will need to remain diligent in improving the efficiency and quality of our products to meet the ever-changing needs of our customers.

BM-Rosendahl and a host of other suppliers will need to be ready and willing to improve their response

times, provide specialized engineering & design support and implement AI and advanced automation tools to meet these new challenges and changes in our industry.

Did you know?

Approximately one in four batteries sold in the U.S. and Canada are made at plants in Lyons Station, PA or Corydon, IA to power cars, tractor trailers, motorcycles, lawn mowers, off-road equipment, golf cars, wheelchairs, boats, lift trucks, mining vehicles, locomotives, solar power systems, wind turbines, telecommunications systems, cable television networks, data centers and much, much more.

you may also like

contact

get in

touch

with us