Check the X-factor in lead-acid battery production

November 29th, 2023

Production downtime, operator intervention, defect elements. All that costs time and money in the overall production process. Here the X-factor in automotive lead-acid battery production comes into play.

share

Our superhero in lead-acid battery production

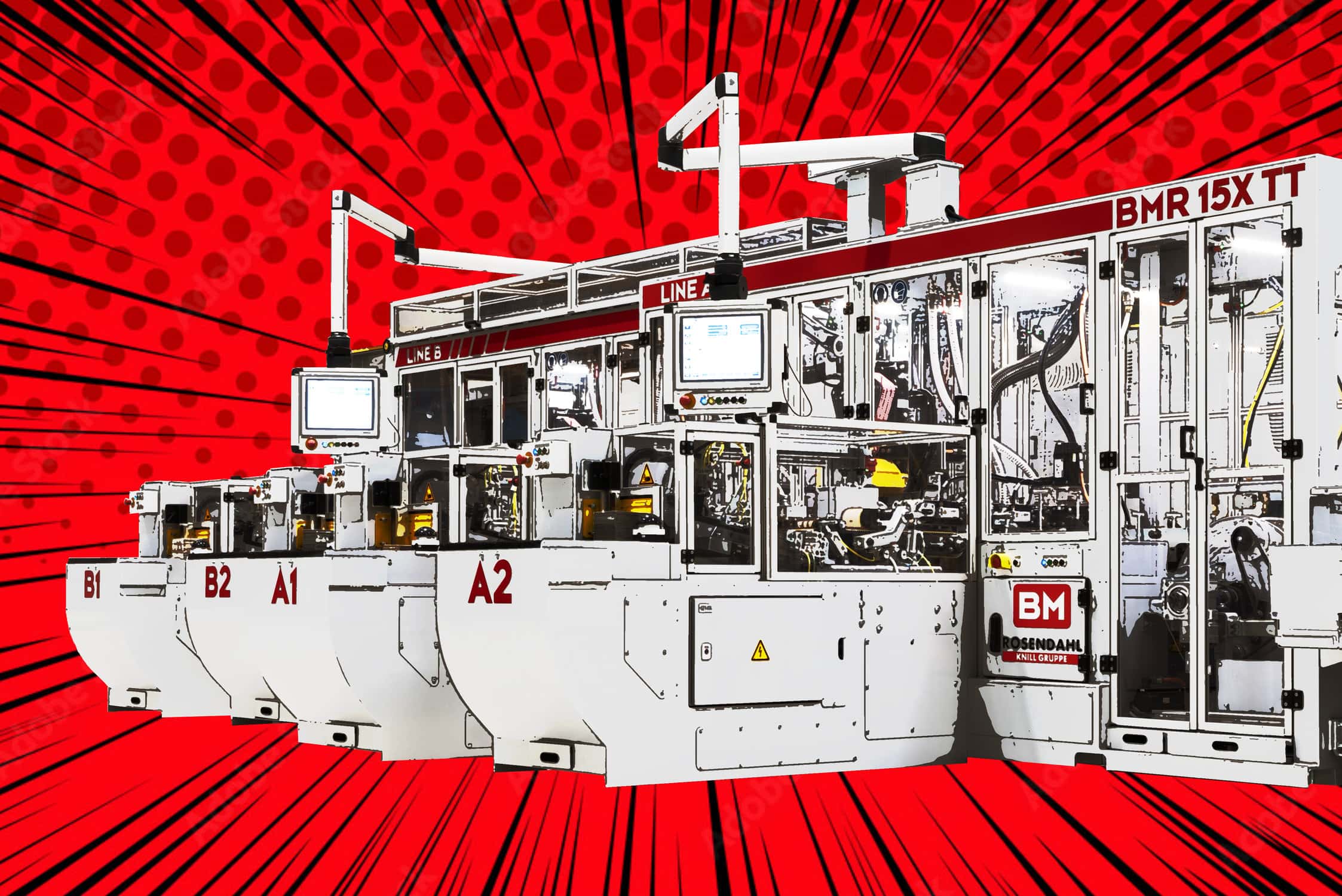

Automotive lead-acid battery production is a well-known process and still the requirements and regulations rise, and unforeseen challenges may occur. In our enveloping machine BMR15X TT, which is a combination of 2 BMR15 machines in 1 machine frame, we put our focus on keeping productivity as high as possible.

The solution: With our technical superhero called “X-factor” you can automatically detect and repair defect elements during running production. It is a proven system that makes us and our existing customers happy and relaxed.

The X-factor

- automatically rejects double plates

- automatically handles missing plates

- automatically rejects “short” separators

- automatically homes

All these technological aspects lead to:

continuous production process

less operator intervention

higher production efficiency

fast, faster, BMR15X TT

The BMR15X TT in general is processing both PE and AGM separators and is currently the fastest and most efficient enveloping & stacking machine on the market. It comprises plate feeders for horizontal plate stack loading of typical starter batteries.

more technical features

- horizontal plate feeding unit

- without additional equipment ready for automatic stack loading

- new controlled vacuum opening at overhead vacuum belt via motor activated valve included in the basis machine

- faster change over time at the plate feeding units

- Aipsum dolor sit ame

technical data

- 340 PE env/min

- 280 AGM env/min

- 4 feeder version only

- handles softer plates

- upgradeable for automatic plate loading

you may also like

contact

get in

touch

with us