are you investing in renewable energy? we are.

May 23rd, 2016

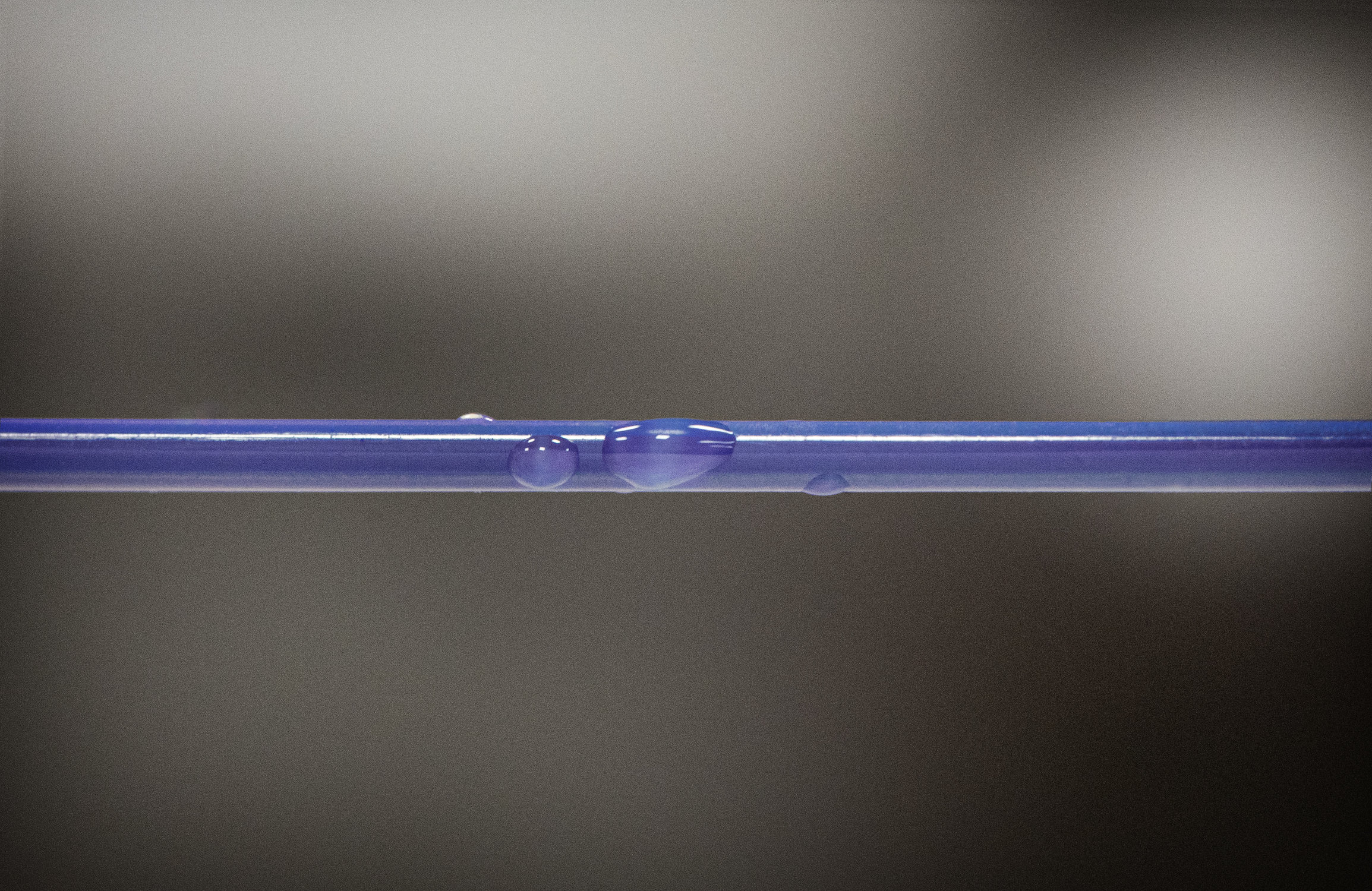

Renewable energy is booming. Not only single households, but more and more companies are also changing their power supply sources. Solar energy is one of these sources that is transmitted through solar cables.

share

Renewable energy is booming

Not only single households, but more and more companies are also changing their power supply sources. Solar energy is one of these sources that is transmitted through solar cables.

And these have special properties to fulfill environmental requirements: they need to be UV resistant, weather resistant and mechanically resistant, as well as offer electrical properties with an ideal lifetime of more than 25 years.

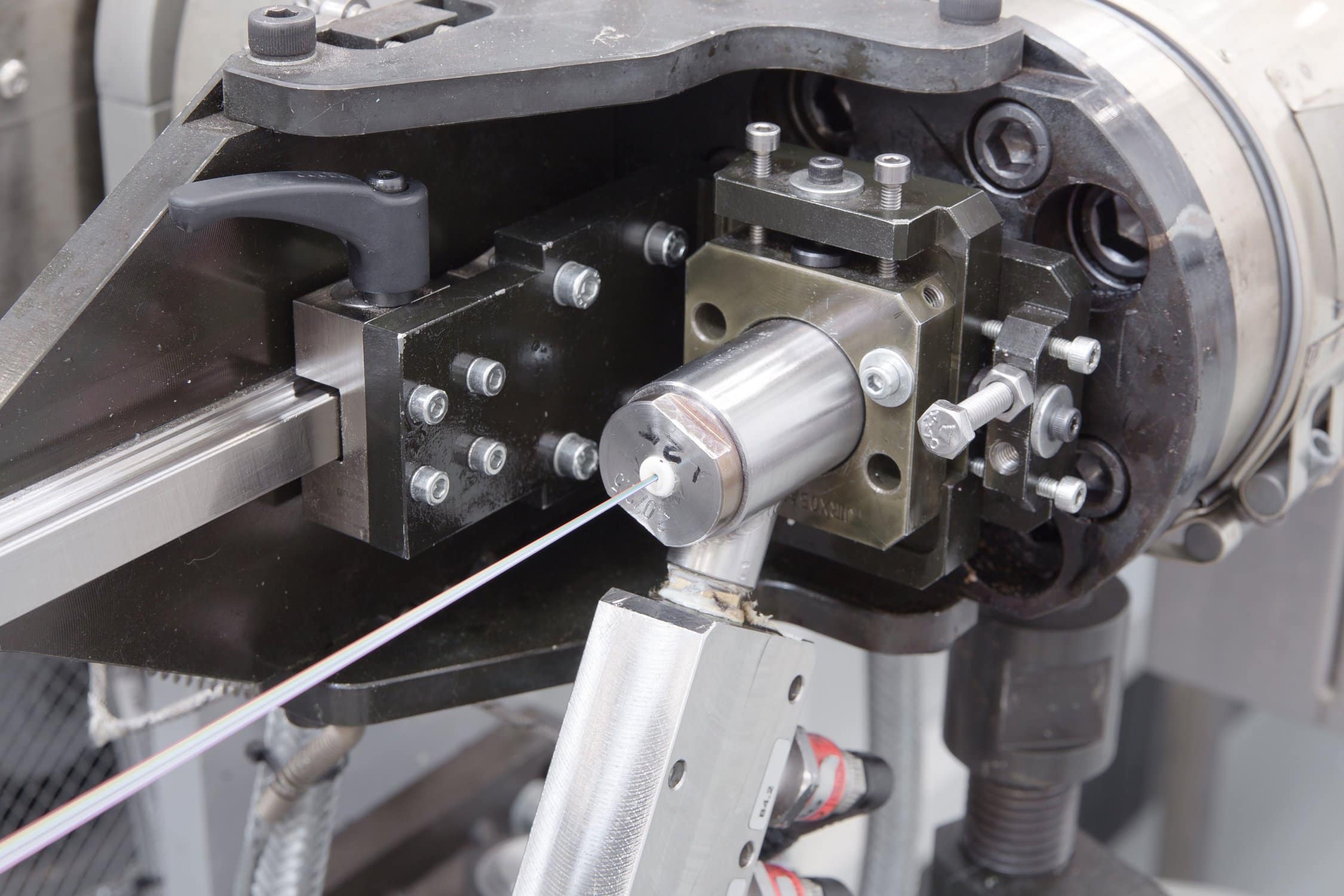

We at Rosendahl deliver extrusion technology for the production of single and multi-core solar cables. The process covers insulation and jacketing in one production step on two extruders of a similar size. An optional stripe extruder can be included in the extruder group.

The latest standards, International IEC 62930 and European Standard EN 50618, also allow the process to run co-extrusion (dual-layer extrusion with one crosshead).

Our experience has shown the utmost results and we are happy to assist you with your individual solution.

Your advantages with Rosendahl co-extrusion are:

- Thinner walls on solar cables

- Higher production speeds

- Easy operation, as it is only one extruder group

- Lower investment costs

- Shorter line length

The extrusion process calls for intense product know-how. The material is typically a polyolefin copolymer which is then crosslinked using either an electron beam or the sioplas method to achieve the desired product quality. These two methods help the material attain a rigid molecular structure for chemical resistance and mechanical flexibility. The material characteristics can be tailored to suit custom needs.

you may also like

contact

get in

touch

with us