Cable & Wire Fair India 2025

when?

Nov 04th – Nov 06th, 2025

where?

Pragati Maidan Booth 3R2-1 New Delhi India

contact person

Aman Arora

+91 888 44 01 101

aman.arora@rosendahlnextrom.com

share

Meet as at booth 3R2-1

From building wire to e-mobility:

Future-ready solutions for a growing nation

We are returning to New Delhi with a portfolio tailored to the needs of India’s dynamic cable industry:

High speed meets high quality

We combine speed, precision, and efficiency to deliver real value to our customers. Our high-speed insulation technology ensures minimal material waste, maximum product consistency, and seamless color changes. With production lines designed for quick changeovers, fast stabilization, and a high degree of automation, you gain greater flexibility and higher output. These advantages are especially beneficial for low-voltage applications such as building and automotive wires, where frequent color changes and reliable performance are key to staying competitive.

Increasing production capacity in datacom and telecom

Our high-temperature physical foaming lines deliver impressive data transmission rates and ultra-low latency, helping supercomputers think faster. We also offer a new generation of datacom core insulation lines for CAT 7 and CAT 8 compliant cables with a skin-foam-skin construction.

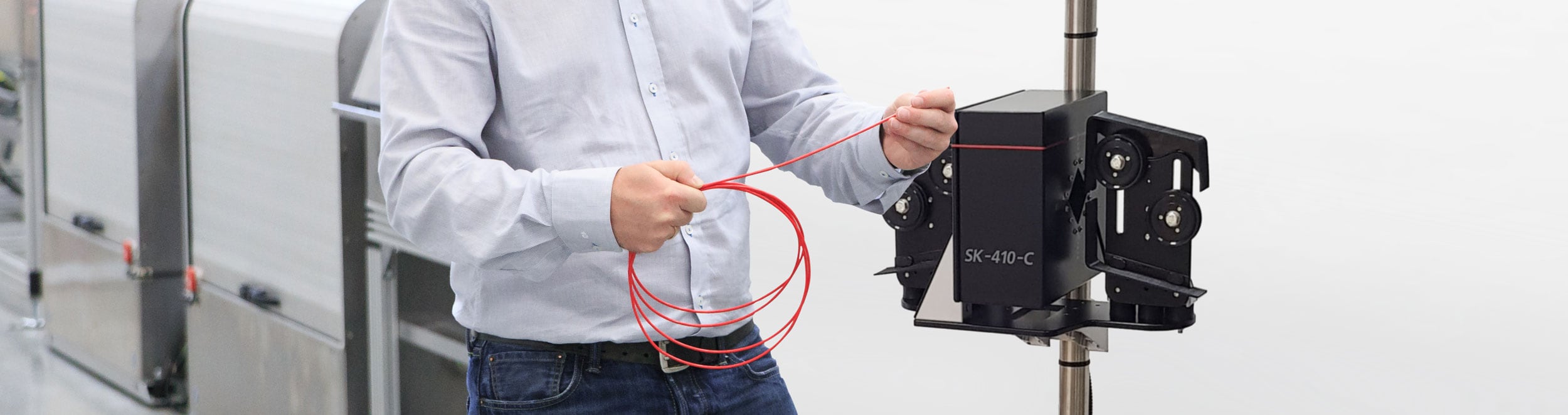

Recent advancements in fiber optic cable production include a high-speed fiber launching unit, an upgraded jelly-filling system, a redesigned fiber cutter, compact clenching capstans, efficient high-speed drying, and a full set of tools to manage EFL variations. Together, these solutions minimize downtime and material waste while raising productivity to the next level.

Greater efficiency for solar cable production

For the booming solar sector, Rosendahl Nextrom presents its latest co-extrusion solution. Applying insulation and jacketing in a single step simplifies the entire production process, resulting in higher production speeds, easier operation, lower investment costs, and shorter line length.

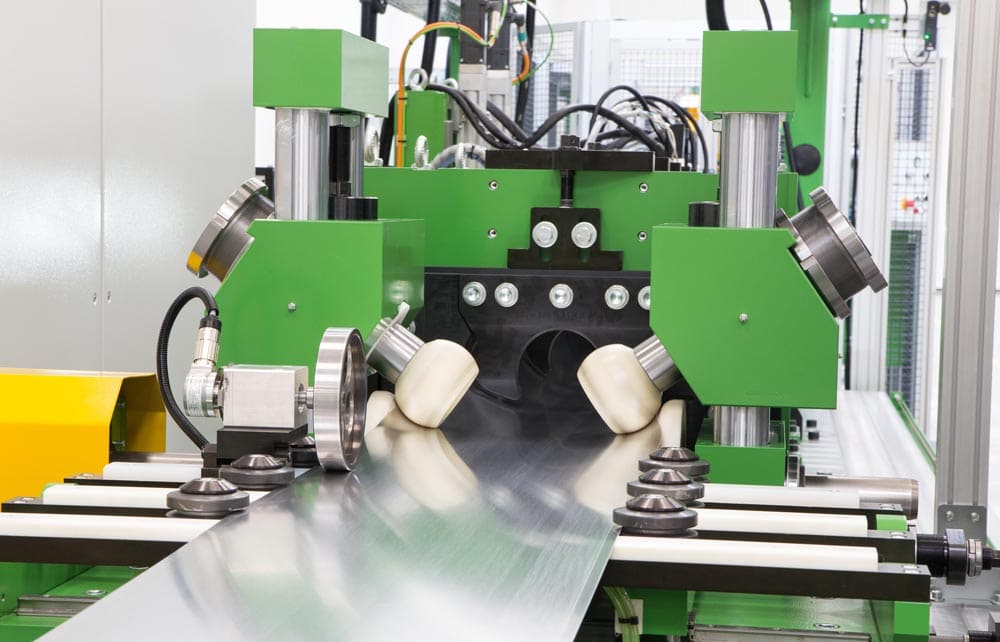

Powering the grid – offshore and onshore

Our powerful metal tape-forming and welding line processes copper, aluminum, stainless steel, and alloys to provide optimal protection in both subsea and land environments. The technology is ideal for connecting wind farms, photovoltaic farms, and offshore projects to the power grid, and opens up many possibilities for HV cable manufacturing.

Future-proof solutions for e-mobility

Automotive producers can look forward to new solutions for the industry, including busbar insulation, high-end charging cables and high-performance data cables. We also offer the world’s first turnkey extrusion line for hairpin insulation for safe and reliable power supply at 800V+.

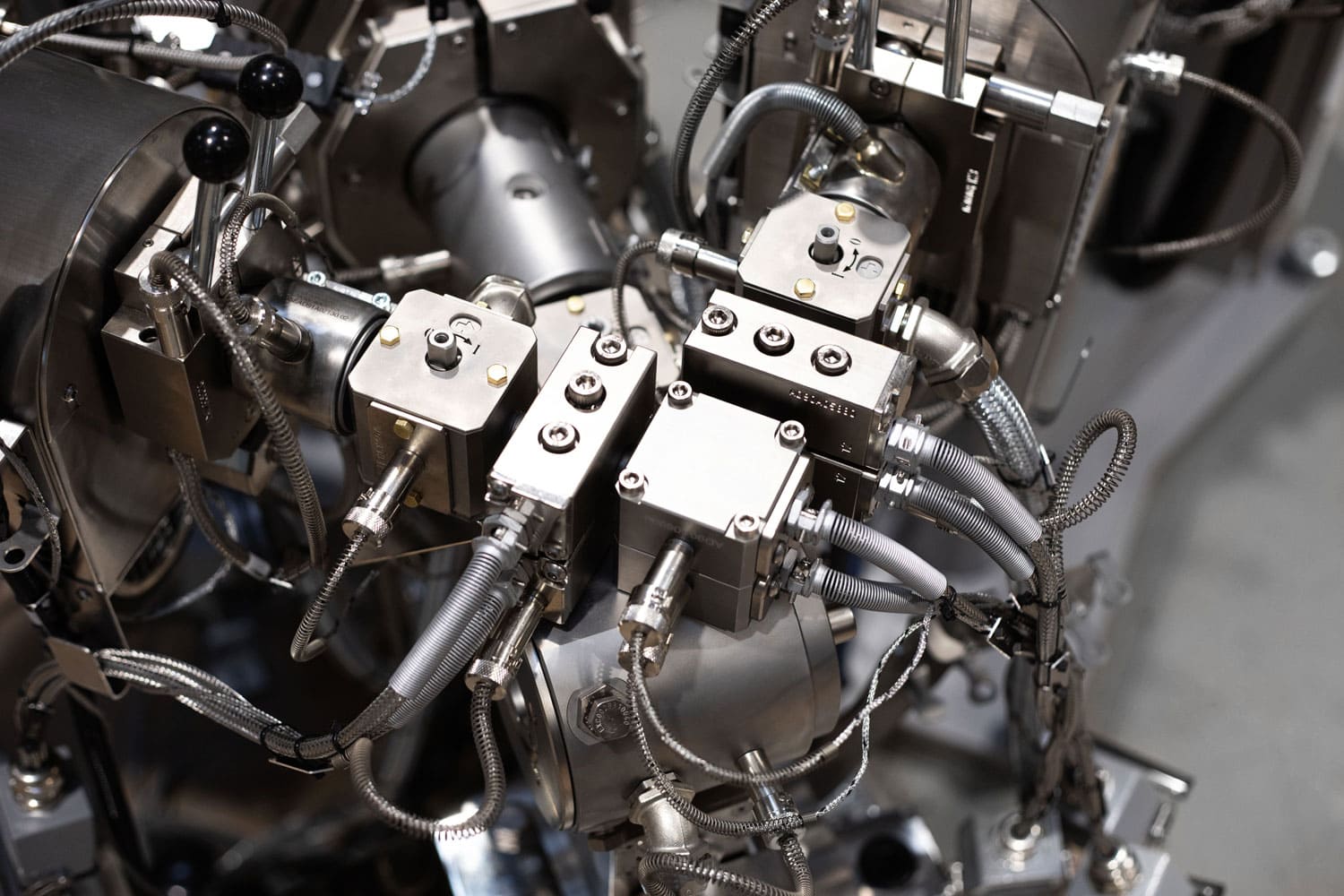

Advanced extrusion technology

At the heart of our extrusion lines is the ROEX technology, which features a unique extruder drive and wear-resistant screws and barrels for high linearity and stable output. The equipment is maintenance-friendly, energy-efficient, built for long-term performance, and ensures repeatable quality.

Innovating smart

A central focus of our work is the thoughtful use of materials, waste reduction, minimizing wear, and enhancing energy efficiency. All machines are orchestrated by our RIO line control. From pay-off to take-up, RIO places every parameter, recipe and diagnostic at the operator’s fingertips, adding AI-assisted process tuning, real-time CO₂ and energy dashboards, and predictive maintenance tools that keep production running smoothly day after day.

Offering lifetime support

We are a strategic partner for cable and wire producers worldwide. Customers can expect first-class support throughout the entire lifetime of their machines. We have maintained a dedicated sales and service unit in India for over 20 years for quick and reliable on-site support.

Visit our experts at booth 3R2-1 to learn more

We are looking forward to welcoming you!

contact

get in

touch

with us