wire 2024

when?

Apr 15th – Apr 19th, 2024

where?

Messe Düsseldorf | A60 | Hall 9 Stockumer Kirchstraße 61 Düsseldorf Germany

share

Balancing quality, productivity, and sustainability is an ongoing challenge for cable and wire producers. As a technology leader, we consistently question conventional manufacturing methods, and explore possibilities for improvement. Sometimes, a small enhancement to a machine can have a significant impact. At times, it's necessary to rethink the manufacturing process of a product from the ground up.

At wire 24, we will proudly present our latest advances in manufacturing technology:

Hairpin extrusion:

a future-proof solution for e-mobility

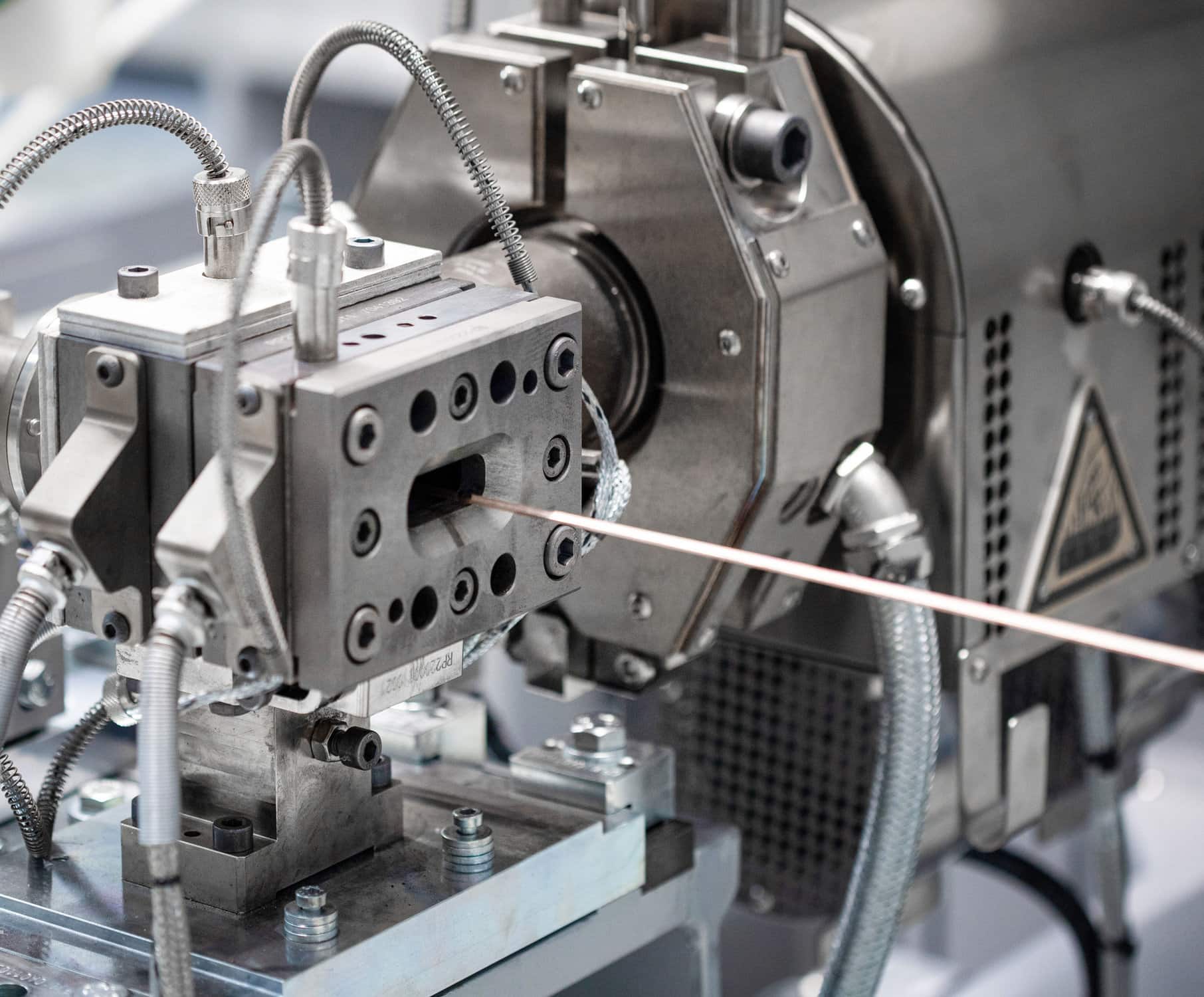

We have recently introduced the world’s first turnkey extrusion line for hairpin insulation. It makes a safe and reliable power supply at 800V or higher possible. With this solution, the much slower and less efficient enameling process faces strong competition. The exceptionally robust insulation with high-performance plastic will contribute to reduced charging times and increased ranges by minimizing energy losses in electric board systems. This will surely boost the attractiveness of e-mobility.

Increasing production capacity in datacom and telecom

The demand for high-speed data infrastructures continues, as does our R&D work in this area. We haves recently installed the world’s most sophisticated laboratory lines for LAN cables and loose tubes at our in-house technology center. Both lines are optimized for high-speed production and equipped with many standout features for scrap reduction, quality control, and automation – an impressive mix of R&D work and engineering excellence to be multiplied in factories worldwide.

Nextrom is revolutionizing preform manufacturing with a combination of Vapor Axial Deposition and Outside Vapor Deposition technologies tailored for producing large-sized preforms with the lowest operational expenses. Furthermore, the telecom fiber drawing process has been optimized to reach impressive speeds of up to 3,500 m/min.

The latest achievements in fiber optical cable manufacturing include a high-speed fiber launching system, a high-speed rewinding line and a proof testing & fiber coloring line with automated reel changes. With these new solutions, emphasis was placed on reducing operating time and scrap while increasing productivity, quality, and safety for operators.

Accelerating energy transition

To facilitate and support the industry’s shift towards a more sustainable power supply, we offer a comprehensive set of solutions. Our sustainable concept for forming, welding, and jacketing flexible materials and product sizes on a single production line is well-suited for connecting wind farms, photovoltaic farms, and offshore projects to the power grid.

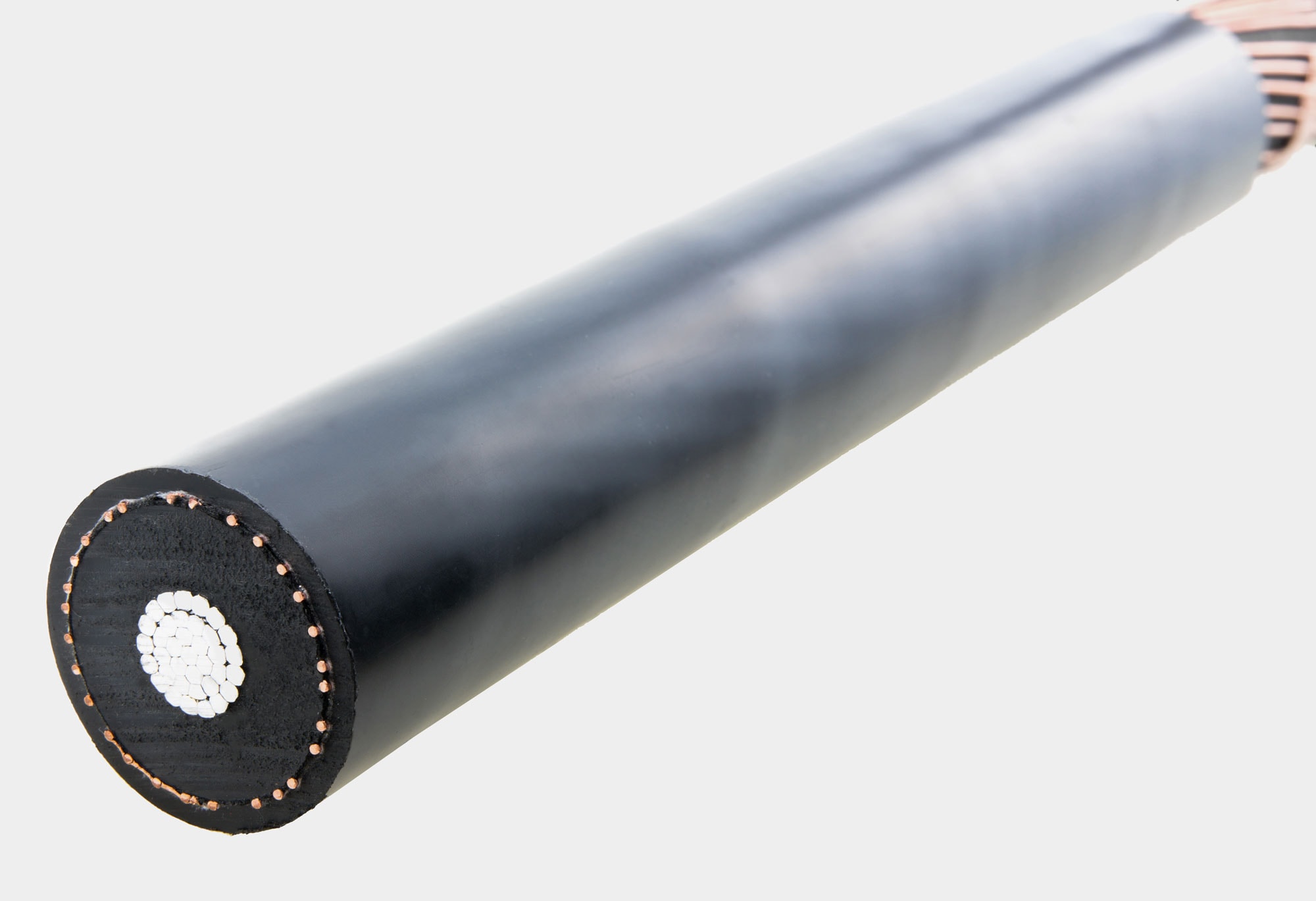

In the medium-voltage segment, the use of recyclable polypropylene-based compounds eliminates the need for energy-intensive cross-linking. This new manufacturing concept creates a compact and sustainable alternative to conventional XLPE solutions without compromising on electrical properties.

Innovating smart and responsibly

Along with high performance comes high responsibility. A major focus of our efforts is the thoughtful use of materials, waste reduction, minimizing wear, and enhancing energy efficiency.

Our powerful line control offers a wide variety of possibilities to continuously improve production in all those areas. ESG-compliant measurement of CO2 and energy consumption has been added to our smart portfolio, ready to support the green transition in the industry. Another user-friendly yet powerful solution has been designed to simplify the complex task of maintenance management. Customers who integrate it into their workflow can expect increased equipment reliability, reduced downtime, and improved operational efficiency.

In the field of telecom fiber drawing, Nextrom is leading the way towards more sustainable production: A Helium Recovery System recovers up to 90% of the used helium, effectively reducing dependence on this limited resource. The return on investment for this system can be achieved within a year, considering the current prices and availability constraints of helium. Additionaly, the Nextrom Induction Furnace drastically cuts down on energy consumption.

Offering lifetime support

We are a strategic partner for producers of cable and wire worldwide. Customers can expect first-class support for the entire lifetime of their machines. To further improve ongoing collaboration, the company has launched a digital customer portal, and improved their warehouse infrastructure. Attractive new service packages and fast, uncomplicated support worldwide round off the selection.

Visit us at booth A60 in hall 9!

Explore innovative extrusion technology and sustainable manufacturing solutions with interactive exhibits and experience a touch of magic.

you may also like

contact

get in

touch

with us